Bending preload micro-nano indentation mechanical properties test method and device

A test device, micro-nano technology, applied in the direction of using stable bending force to test the strength of materials, measuring devices, scientific instruments, etc., can solve problems such as the inability to meet new technologies, and achieve high test accuracy, compact structure, and reasonable layout. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation plan

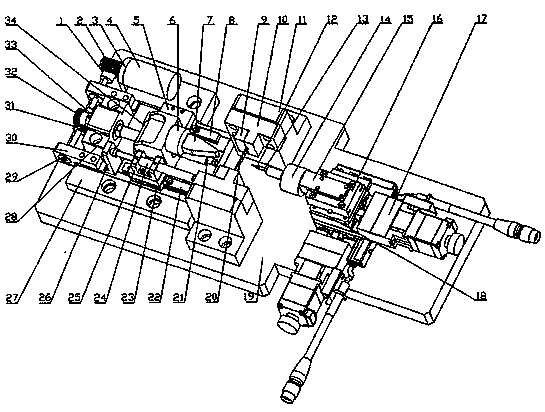

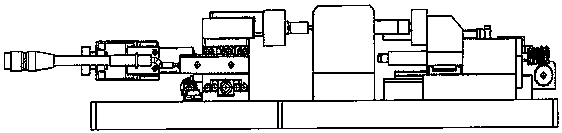

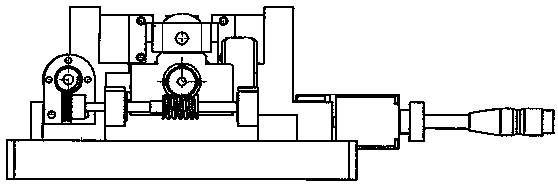

[0023] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0024] see Figure 1 to Figure 7 A bending preload micro-nano indentation mechanical performance testing method and device integrates two parts, the bending loading unit and the micro-nano indentation loading unit, and the bending loading module and the micro-nano indentation loading module are respectively fixed on two sides of the marble floor On the side, the bending loading indenter and the indentation loading indenter are coaxial and installed symmetrically with the fixture, so that in-situ mechanical performance testing can be performed under the composite loading mode of bending preload micro-nano indentation. The mechanical behavior under combined load provides a new test method.

[0025] The drive module of the bending loading unit is composed of a precision DC serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com