An electromagnetic Hopkinson torsion bar loading device

A technology with loading device and electromagnetic type, which is applied in the field of electromagnetic Hopkinson twisting rod loading device, can solve problems such as unavailable stress waves, and achieve the effects of simple operation, good repetitiveness, and strong controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] This embodiment is an electromagnetic Hopkinson torsion bar loading device and test method.

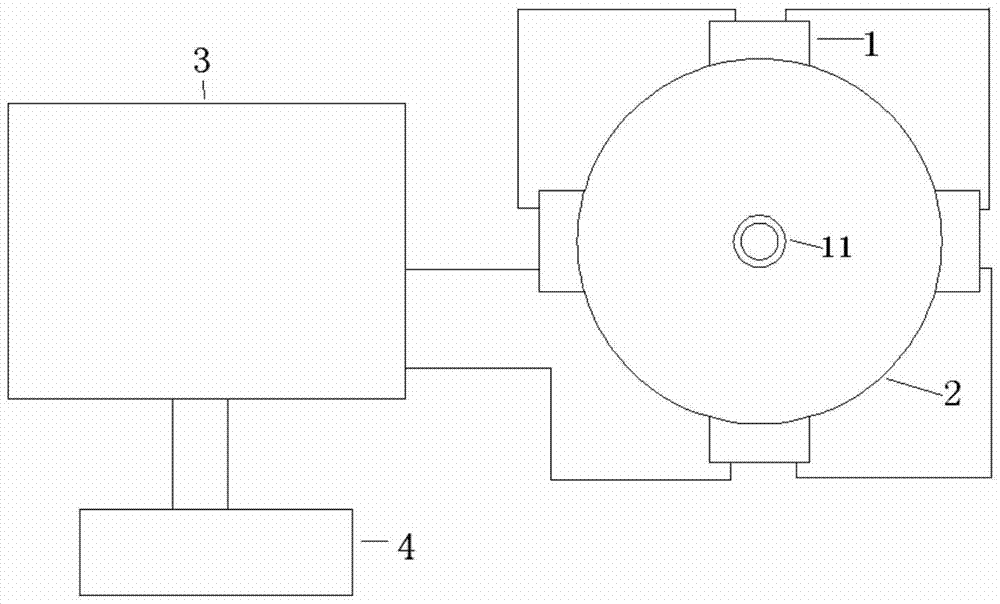

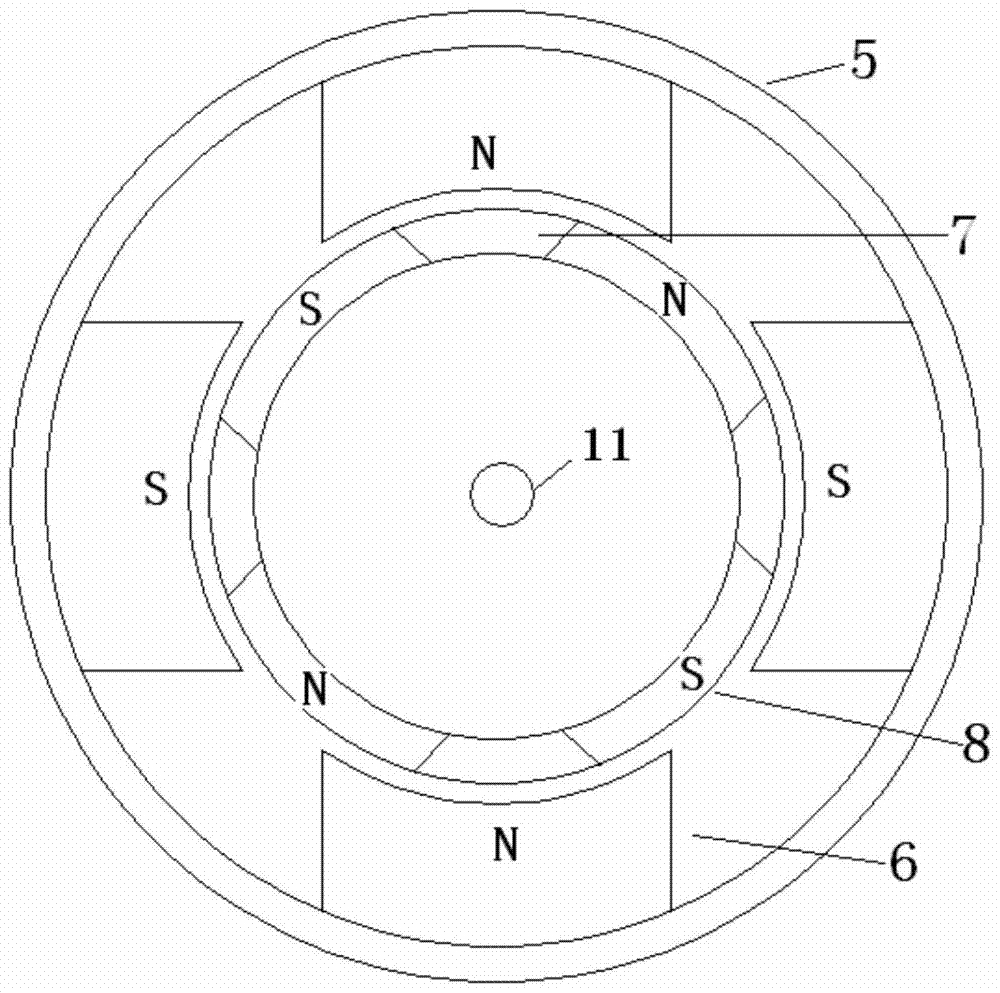

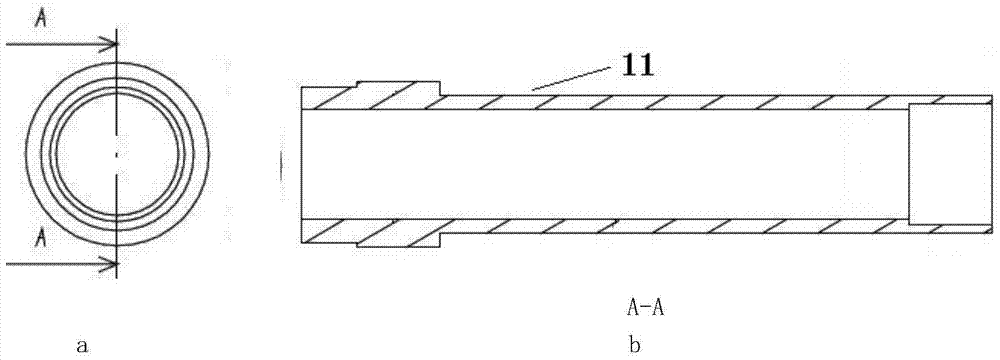

[0039] The electromagnetic Hopkinson torsion bar loading device includes a power supply 4 , an electric energy storage and release device 3 and a torsion gun 2 . Wherein, the torsion gun includes a rotor 7, the joints 22 of the four stators 6 in the torsion gun are connected in series with wires to form a coil group, and the positive and negative terminals of the coils are respectively connected to the electric energy storage and release device 3 The positive output line and the negative output line are connected. The power supply 4 adopts 380V industrial three-phase alternating current.

[0040] In this embodiment, the electric energy storage and release device 3 adopts the power supply part of the electromagnetic riveting equipment published in the patent No. 200520079179, and the power supply part of the electromagnetic riveting includes a capacitor box and a control box. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com