Welding method and assembly tooling of inner and outer cylinders with through-hole support for connecting pipes

A technology of assembly tooling and inner and outer cylinders, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as difficulty in ensuring concentricity and affecting the assembly of air delivery pipes, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

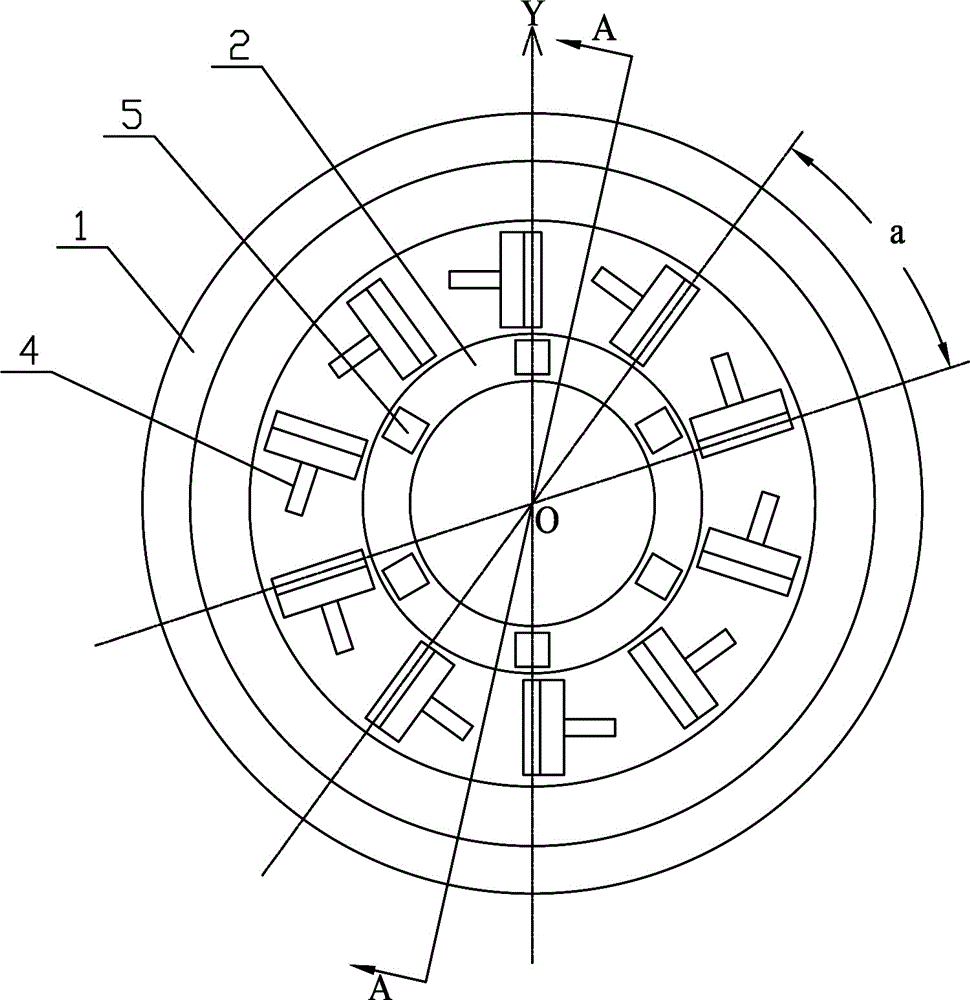

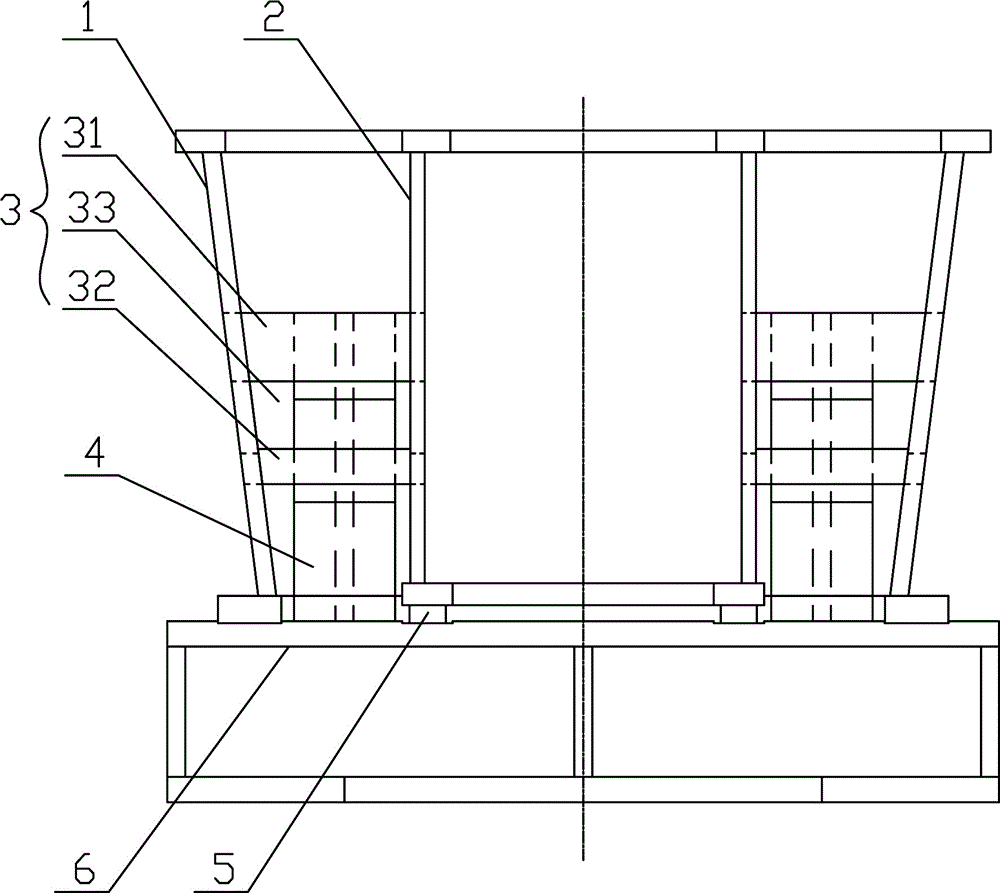

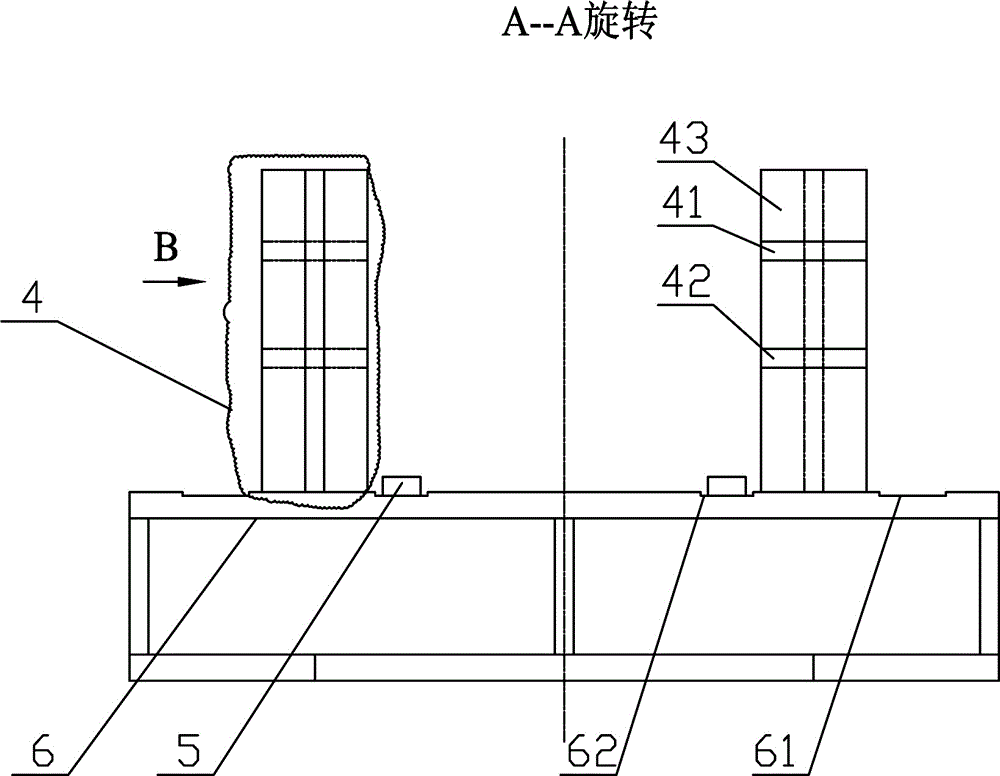

[0036] The takeover structure in this example is as follows Figure 8~10 As shown in , the outer cylinder 1 is tapered, with flanges at both ends, the outer cylinder 1 is divided into two semi-rings by the Huff line 9, the inner cylinder 2 is cylindrical, with flanges at both ends, and the inner cylinder 2 is divided into two half rings by the Hough line 9, wherein the height of the inner cylinder 2 is lower than that of the outer cylinder 1. There are 10 outer cylinder through holes 101 evenly distributed along the circumference on the outer cylinder 1, and 10 inner cylinder through holes 201 are also provided at the corresponding positions of the inner cylinder 2. 201 position, the outer cylinder 1 and the inner cylinder 2 are welded together, and the inner and outer cylinder support 3 with holes is divided into a support upper section 31 and a support lower section 32, and a step is provided on the support upper section 31 and the support lower section 32, and the support c...

Embodiment 2

[0045] A method of assembling welding using the above-mentioned assembly tooling with through-hole support on the inner and outer tubes of the connecting pipe, comprising the following steps:

[0046] 1. Process the upper support section 31 and the lower support section 32;

[0047] Such as image 3 , 4 Among them, the positioning of the supporting and positioning tooling 4 has a tolerance of ±0.05mm. Here the size is used to control the size of the support through hole 33 . Grooves for positioning the inner and outer cylinder flanges are processed on the upper plane of the assembly tooling base 6, namely the outer cylinder flange positioning groove 61 and the inner cylinder flange positioning groove 62. The depth of the groove is 5~10mm. Groove assembly of the flanges of the inner and outer cylinders ensures the concentricity of the inner and outer cylinders and the assembly size of the supporting and positioning tooling 4.

[0048] 2. On the tooling base 6, draw the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com