Adjustable and off-tracking-resistant double-faced sand belt polishing machine

An abrasive belt polishing and anti-deviation technology, applied in abrasive belt grinders, grinding/polishing equipment, grinding machine parts, etc., can solve problems such as injuries, potential safety hazards, improper operation, etc., and achieve a large adjustable range , Convenient clamping and polishing, avoiding the effect of offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

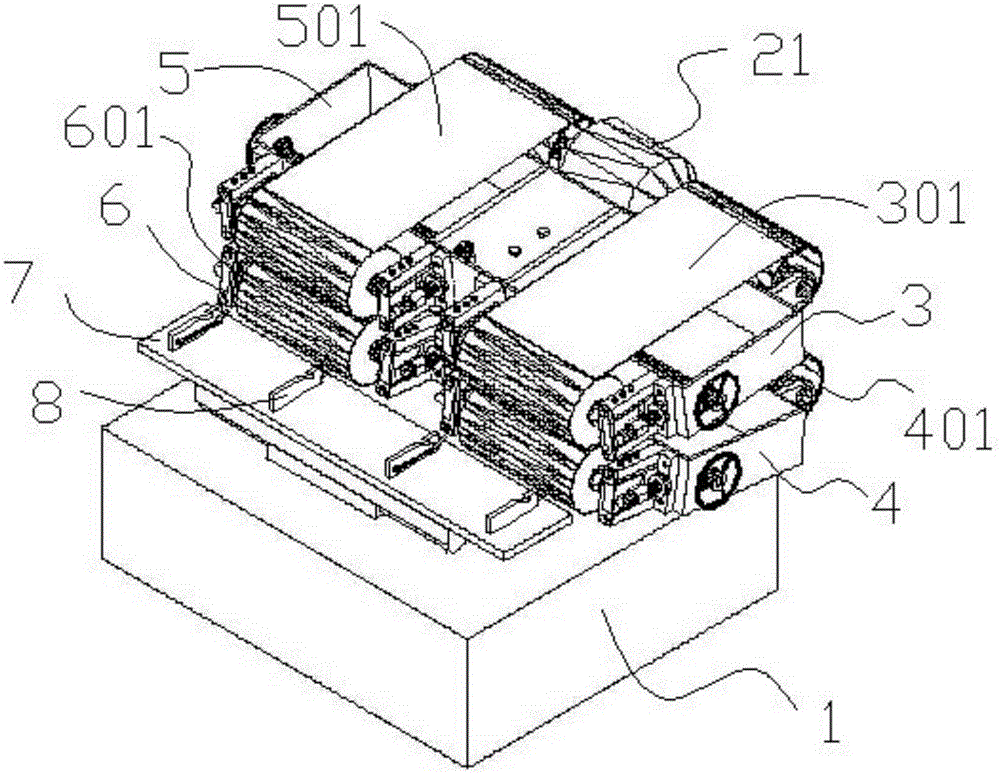

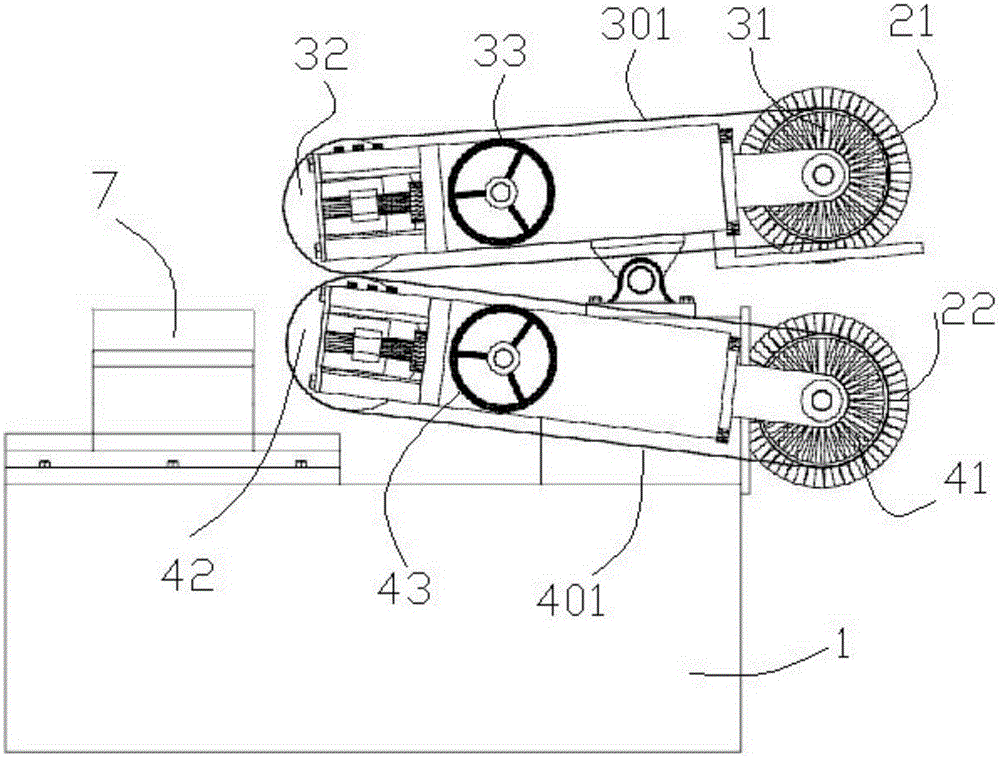

[0038] Concrete structure of the present invention, participate in Figure 2-Figure 8: it includes a base 1, the frame above the base 1 is divided into upper and lower layers and is respectively provided with an upper drive assembly and a lower drive assembly; the upper drive assembly includes: a drive wheel and a driven wheel respectively connected to the two ends of the upper drive 21 , the abrasive belt and the adjusting frame for adjusting the position of the driven wheel and the tension of the abrasive belt between the driving wheel and the driven wheel; The upper drive wheel 51 is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com