Part placement rack

A technology for placing racks and parts, applied in the direction of workbench, manufacturing tools, etc., can solve the problems of low oil removal efficiency, troublesome work, and inability to remove cooling oil, etc., and achieve the effect of ingenious structural design and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

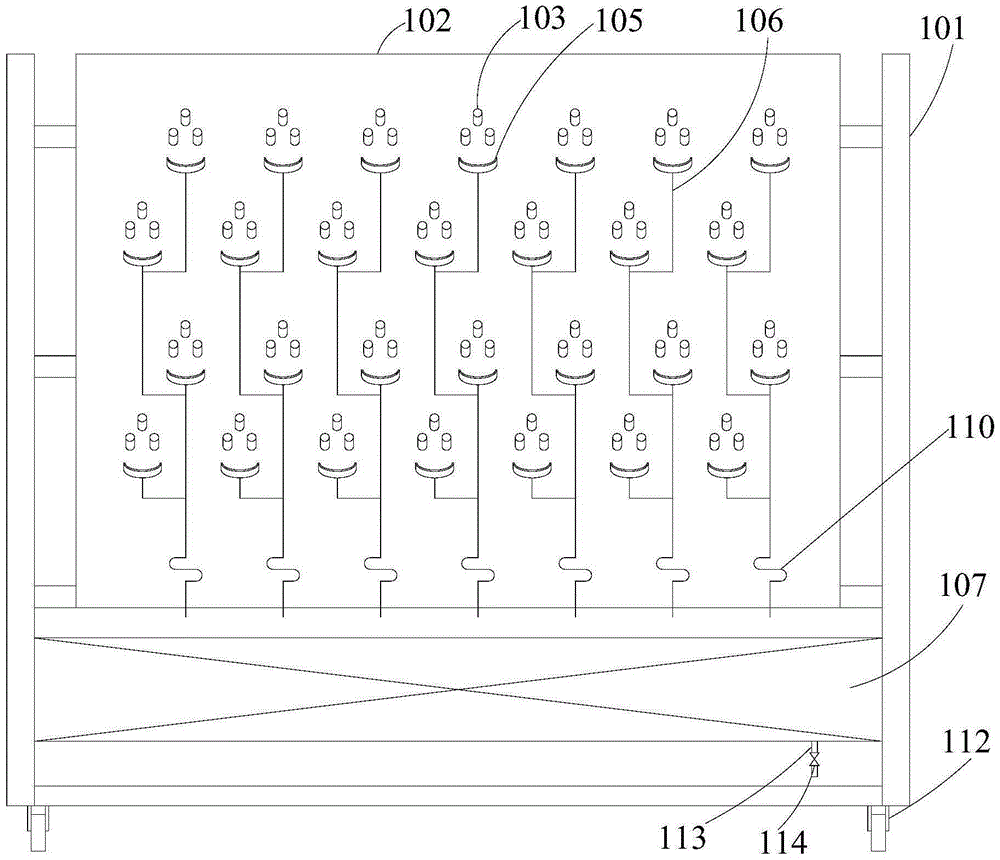

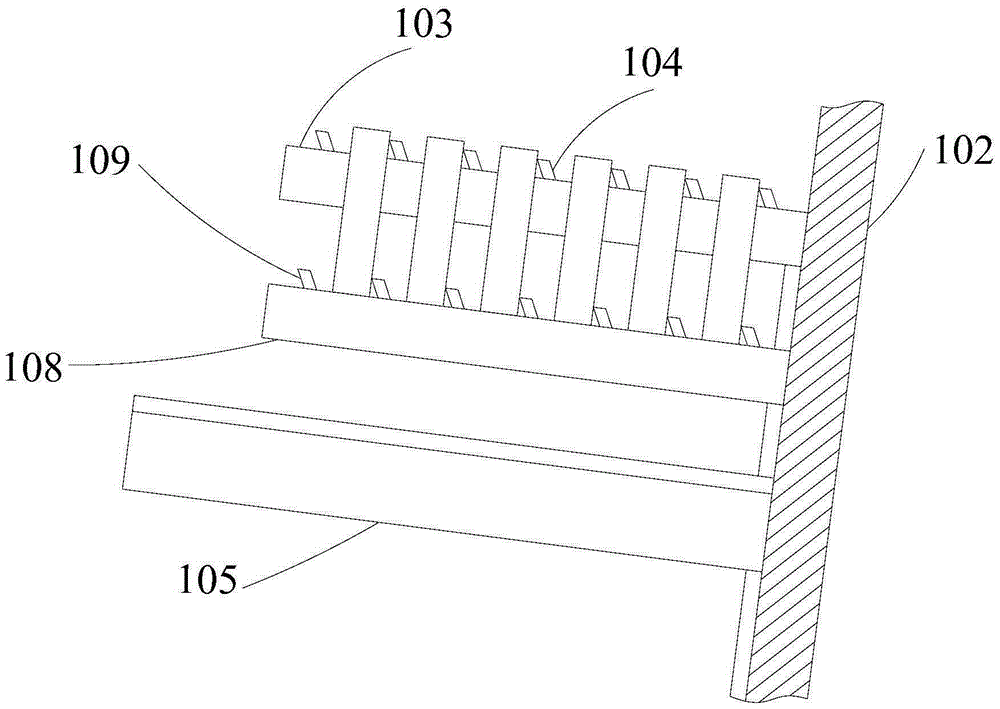

[0059] A parts placement rack, comprising a frame body 101, the frame body 101 includes a placement area and an oil collection area from top to bottom; the placement area includes two sets of suspension mechanisms arranged symmetrically along the vertical plane, and each set of suspension mechanisms includes a Hanging plate 102, each hanging plate 102 is provided with 28 groups of suspension components, the suspension components are divided into four rows, each row has 7 groups; each group of suspension components includes hanging rods 103 arranged obliquely, and the upper part of the hanging rods 103 is along its Seven stoppers 104 are evenly spaced in the length direction, and each set of suspension components also includes an arc-shaped oil collecting plate 105 obliquely arranged under the hanging rod 103, and the bottom end of the oil collecting plate 105 is connected with an oil pipe extending downward 106 ; the oil collecting area includes an oil collecting groove 107 arr...

Embodiment 2

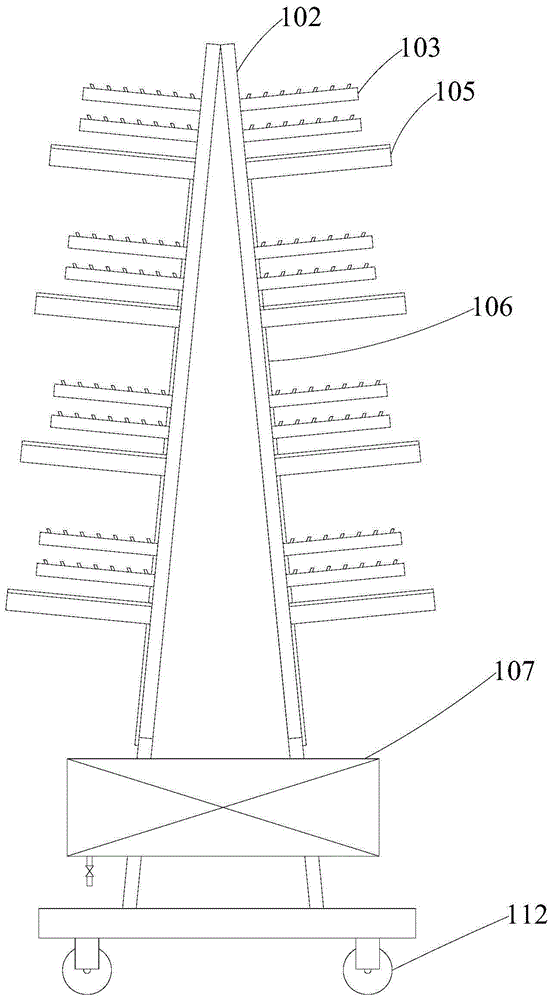

[0061] A parts placement rack, comprising a frame body 101, the frame body 101 includes a placement area and an oil collection area from top to bottom; the placement area includes two sets of suspension mechanisms arranged symmetrically along the vertical plane, and each set of suspension mechanisms includes a Hanging board 102, two hanging boards 102 are all obliquely arranged, and its top is connected, and the bottom is far away from each other, and each hanging board 102 is provided with 28 groups of suspension assemblies, and suspension assembly is divided into four rows, and each row has 7 groups; The set of suspension components includes a hanging rod 103 arranged obliquely. The upper part of the hanging rod 103 is evenly spaced with seven stoppers 104 along its length direction. plate 105, the bottom of this oil collecting plate 105 is connected with oil pipe 106 extending downwards, each hanging rod 103 and each oil collecting plate 105 are all perpendicular to hanging ...

Embodiment 3

[0064] A parts placement rack, comprising a frame body 101, the frame body 101 includes a placement area and an oil collection area from top to bottom; the placement area includes two sets of suspension mechanisms arranged symmetrically along the vertical plane, and each set of suspension mechanisms includes a Hanging board 102, two hanging boards 102 are all obliquely arranged, and its top is connected, and the bottom is far away from each other, and each hanging board 102 is provided with 28 groups of suspension assemblies, and suspension assembly is divided into four rows, and each row has 7 groups; The set of suspension components includes a hanging rod 103 arranged obliquely. The upper part of the hanging rod 103 is evenly spaced with seven stoppers 104 along its length direction. plate 105, the bottom of this oil collecting plate 105 is connected with oil pipe 106 extending downwards, each hanging rod 103 and each oil collecting plate 105 are all perpendicular to hanging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com