Coding system

A coding system and coding technology, applied in the field of coding, can solve the problems of insufficient production capacity and easily scratched glass, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

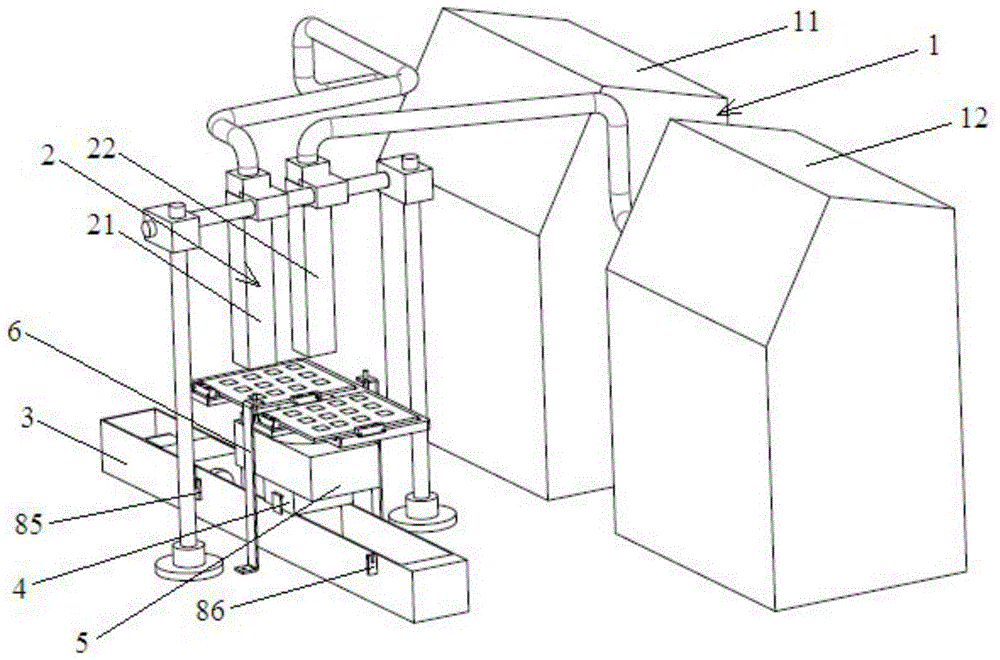

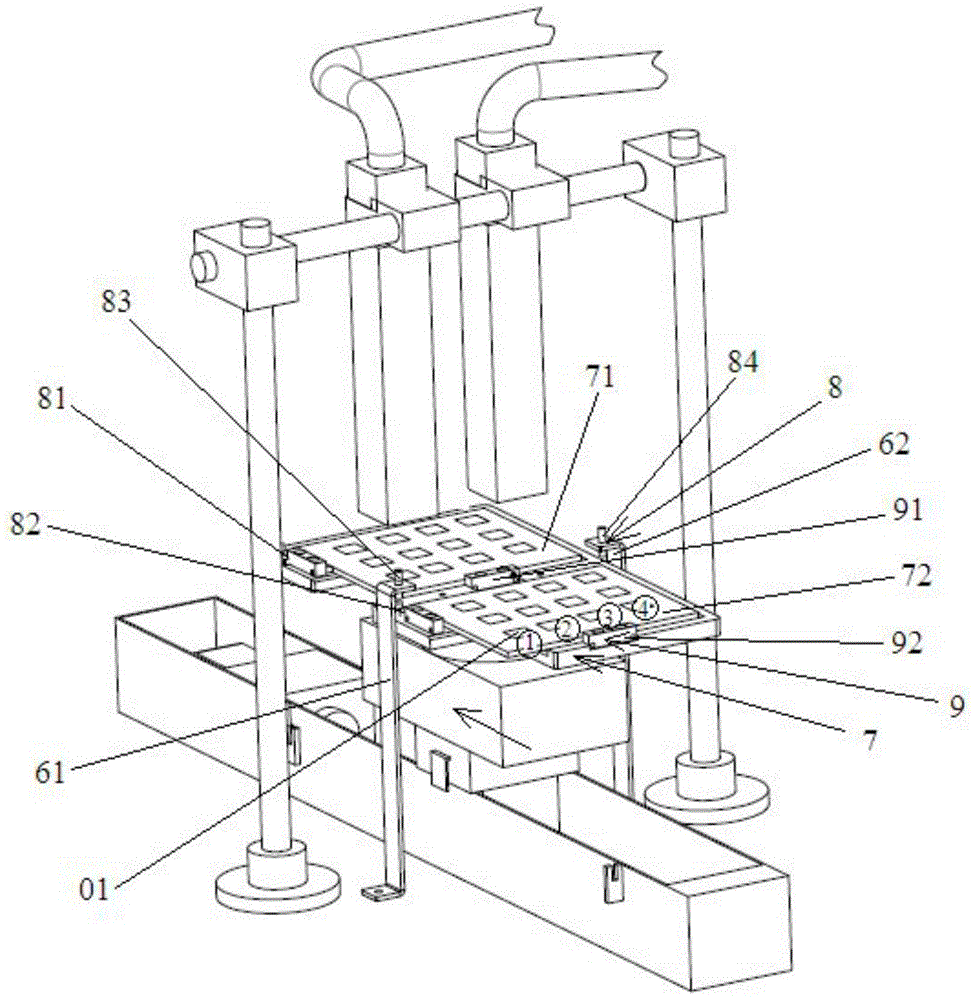

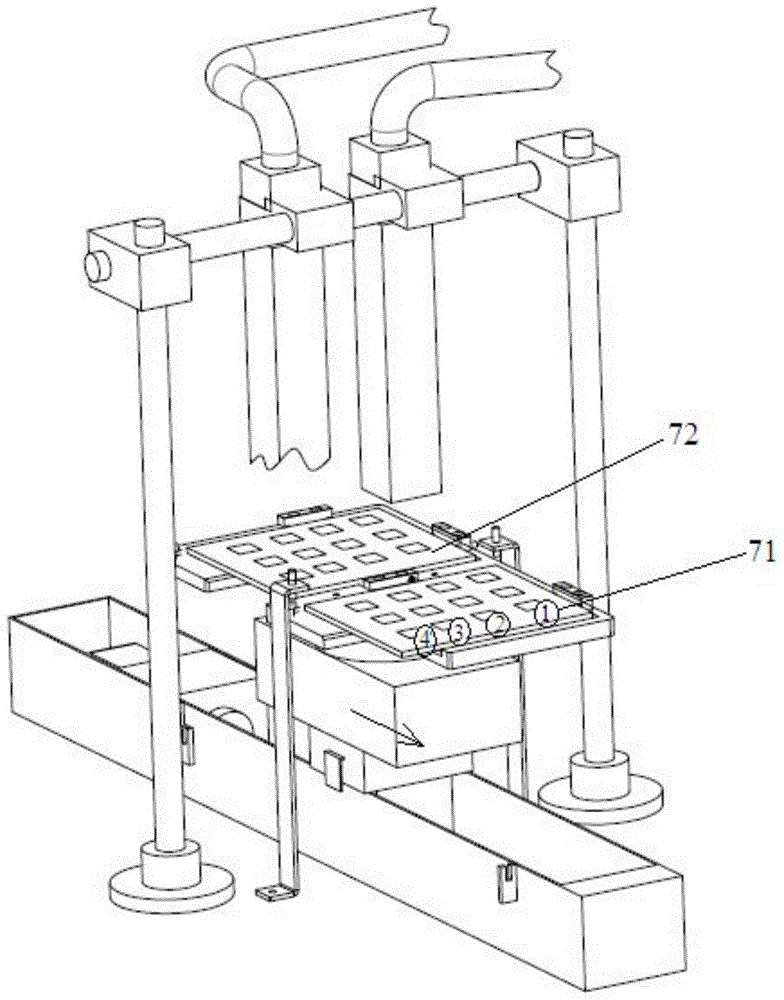

[0030] see Figure 1 ~ Figure 3 , the slide table 4 is arranged above the driver 3, and can move left and right along the length direction of the driver 3, the action stroke is 360mm, and its action speed can be adjusted according to the coding speed of the gun head 2; The rotary cylinder 5 is installed above the slide table 4. The rotary cylinder 5 can be rotated clockwise or counterclockwise by 180°. The clamp 7 of the clamp 72 . The two gun heads 2 are installed vertically above the clamp 7, the distance between the gun heads 2 and the plane of the clamp 7 is 10 mm to 25 mm, and the gun heads 2 include a first gun head 21 and a second gun head 22 , the gun head 1 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com