A Method for Controlling Sewing and Edge Trimming of Pattern Machine with Rotary Cutter Head

A technology of rotating cutter head and pattern machine, which is applied to sewing equipment, sewing machine components, sewing machine control devices, etc., can solve the problem that the control of a pattern machine with a rotating cutter head cannot be applied, and achieve the effect of beautiful trimming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific embodiments.

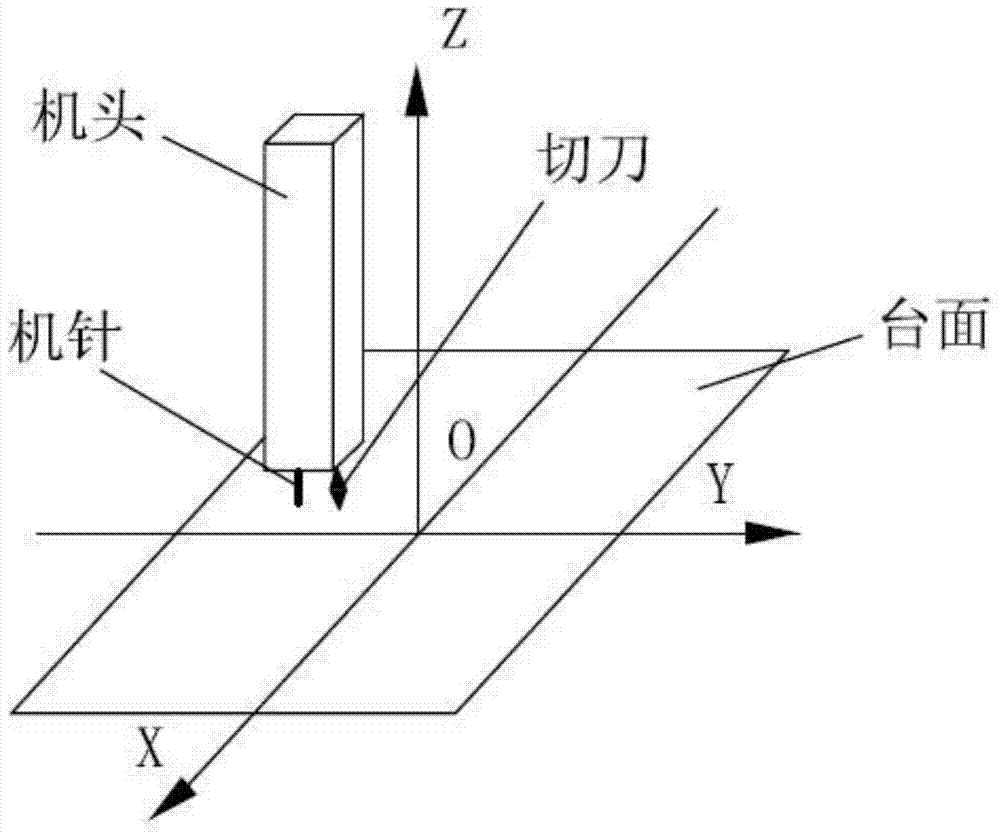

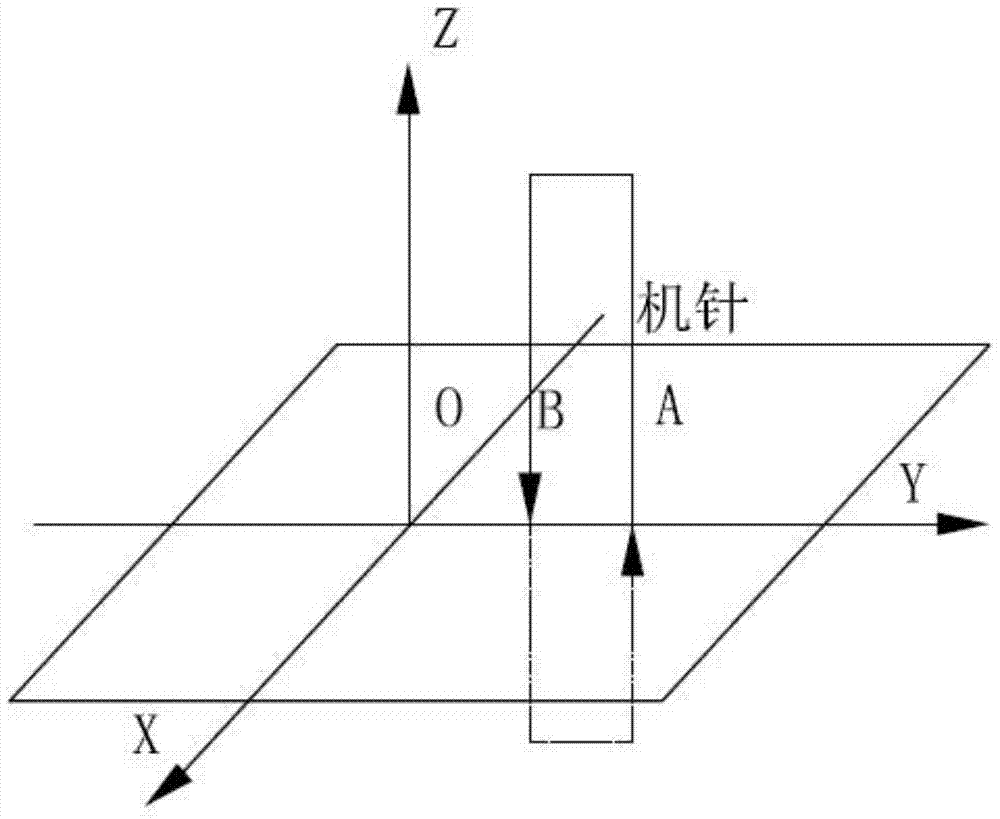

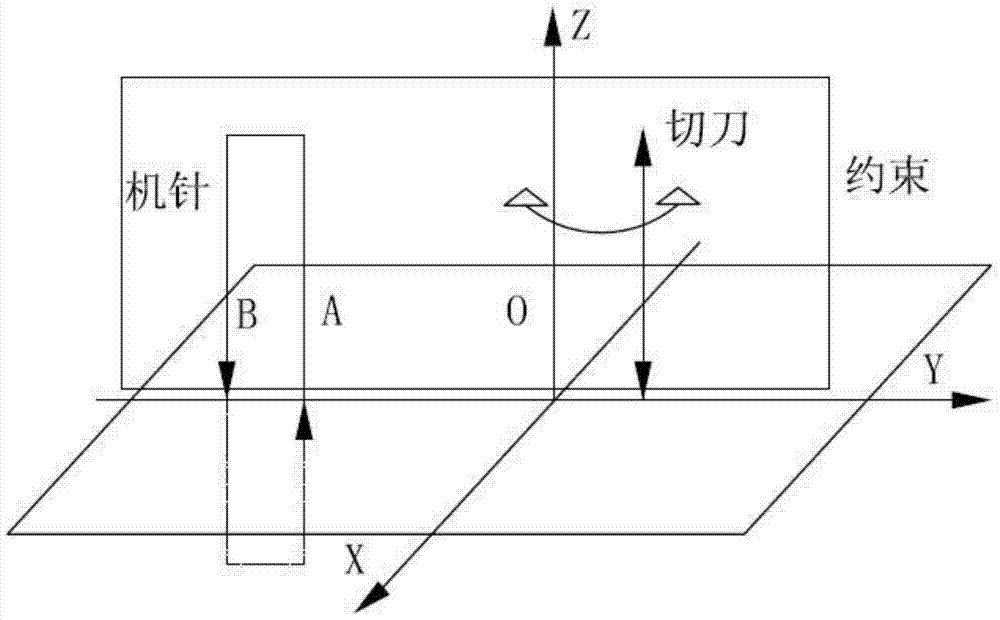

[0035] Such as Figure 1-Figure 5 In this embodiment, the method for controlling the rotary cutter head of the pattern machine with a rotary cutter head to sew and trim the edge includes the following steps:

[0036] Step 1: Establish the calculation formula for the movement of the needle spindle of the pattern machine with a rotary cutter head, the XY axis movement of the feeding frame, the left and right rotation of the rotary cutter, and the vertical cutting speed of the rotary cutter:

[0037]A complete sewing and trimming process is that the needle spindle completes a circle of up and down reciprocating motion, the XY axis of the feeding frame moves the feeding frame according to the current needle displacement, and the rotary cutter rotates left and right according to the rotation angle, and the rotary cutter completes Cutting motion up and down. When the needle i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com