Connecting rod type moving mechanism for automatic sewing unit of garment making device

A moving mechanism, link-type technology, applied in the direction of cloth pressing mechanism, sewing machine components, sewing equipment, etc., can solve the problems of single processing pattern, large space occupation, and the cloth moving path cannot be well controlled, etc. Wide-ranging, space-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

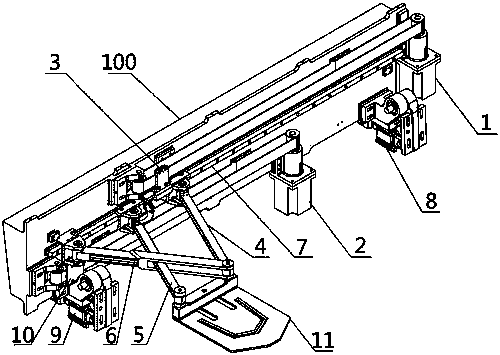

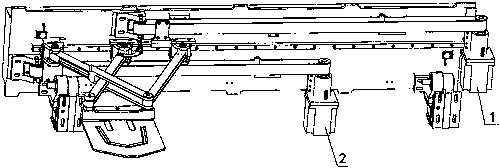

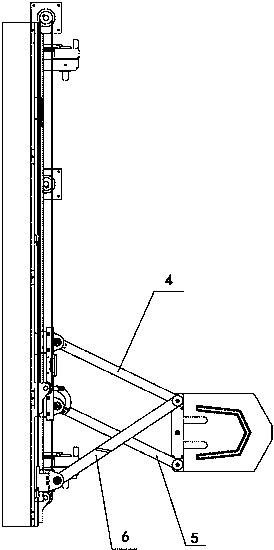

[0033] Such as Figure 1-4 As shown, in the connecting rod type moving mechanism for the automatic sewing unit of the garment-making equipment described in the embodiment of the present invention, one of the objectives to be achieved by the implemented technical means is to solve the problem of the sewing machine feeding of the automatic sewing unit of the traditional garment-making equipment. The direction of plate transport is relatively single and the space is relatively large. Therefore, the technical means implemented in the present invention is to change the running direction of two sets of sliding units with hinged links according to different processing needs on the basis of single-rail operation. Thereby realizing different running directions with reference to the position of the monorail, the implemented technical solution is completed in an intensive space, thus including the machine base casting 100, and the left and right ends of the machine base casting 100 provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com