Marine fuel oil preheating system and its preheating method based on casing form

A technology for fuel oil and ships, which is applied in the charging system, fuel heat treatment device, liquid fuel feeder, etc., and can solve the problems of low efficiency of hot oil transportation, unstable pump motor power, and poor heat exchange effect. , to achieve the effect of improving fuel retention, improving energy utilization, and fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

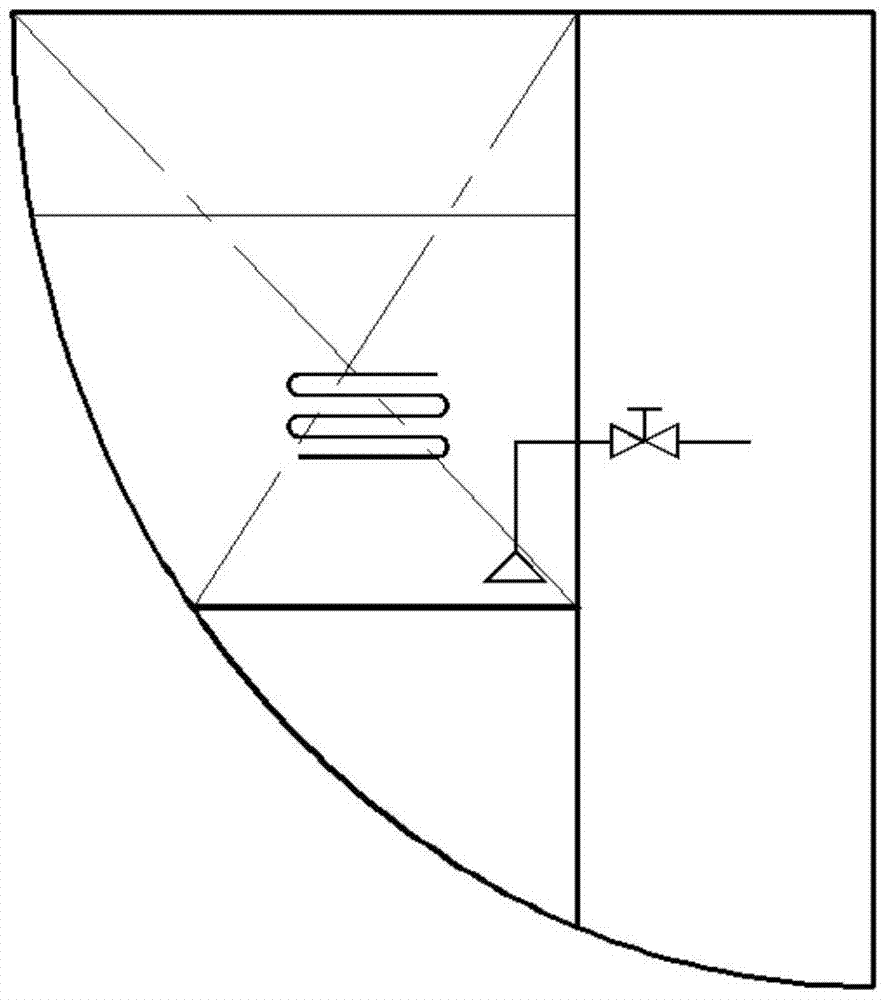

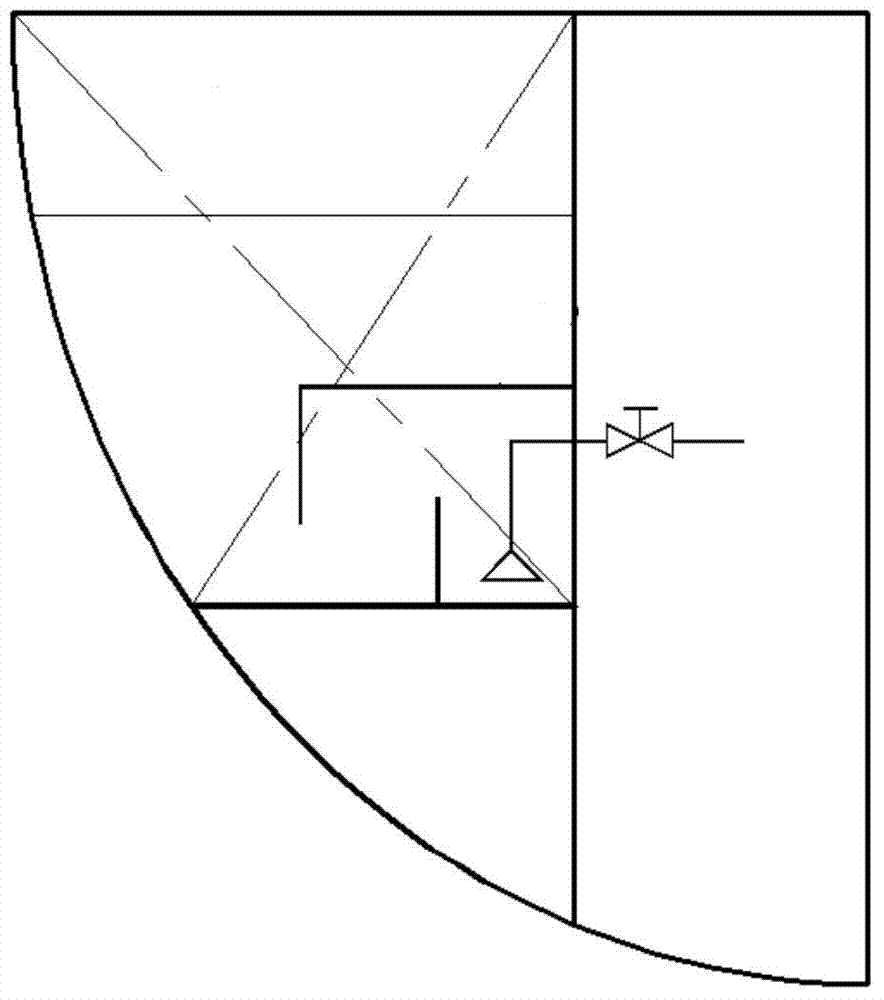

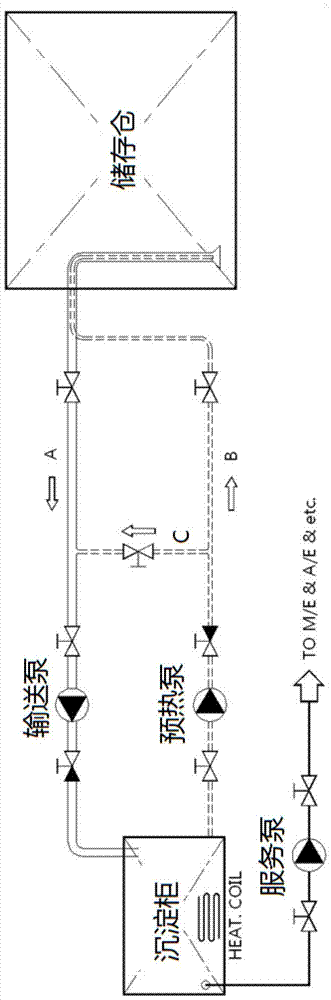

[0044] The specific design scheme of the present invention is as image 3 Shown: Two pipelines for fuel preheating and delivery are set between the fuel storage tank and the fuel sedimentation tank, and the two pipelines are connected. The preheating pipeline is equipped with a fuel preheating pump, which pumps high-temperature fuel from the fuel settling tank to the fuel storage tank where low-temperature fuel is stored; the preheating fuel delivery pipeline is set with a fuel delivery pump, and the heated fuel is delivered to the settling tank. Both branches are provided with cut-off check valves in corresponding directions. The suction port of the high-temperature fuel in the fuel storage tank and the low-temperature fuel in the fuel storage tank have a strong convective heat exchange. After the convective heat exchange, the temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com