Lubricated bearing for petroleum drilling

A technology for lubricating bearings and oil drilling, applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve problems such as large gaps and lubricating oil cannot flow into the other end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

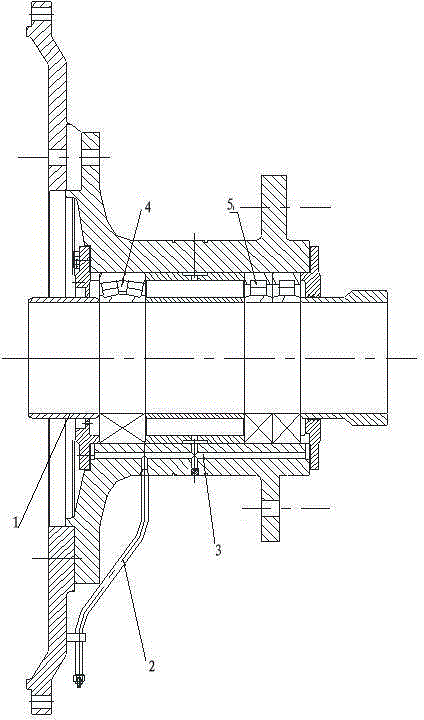

[0011] Such as figure 1 As shown, there is a three-way oil channel 5 in the equipment 1, and the lubricating oil enters the equipment from the lubricating oil inlet pipeline 4, and then flows into the rolling bearings, bearing I2, and bearing II3 at both ends of the lubricating oil along the oil hole channel in the equipment 1. This design draws lessons from the idea and method of forced lubricating bearing bush or sliding bearing, and improves it, forming a new method of forcing rolling bearings at both ends of the equipment at the same time.

[0012] A lubricating bearing for oil drilling, comprising equipment 1, bearing I2 and bearing II3 installed on the equipment 1, oil inlet pipeline 4 and oil passage 5 inside the equipment are arranged on the equipment 1. The oil passage 5 can lead the oil passage 5 to the inside of the equipment 1 that needs to be filled with grease through an additional pipeline. Oil holes are arranged on the outer bearing caps of the bearing I2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com