Detection tool for detecting machining size of left-center-right support

A technology for processing dimensions and right brackets, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of insufficient batch supply, qualified, and inability to determine the left, middle, and right brackets, etc., to achieve convenient detection and improve Work efficiency and the effect of saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

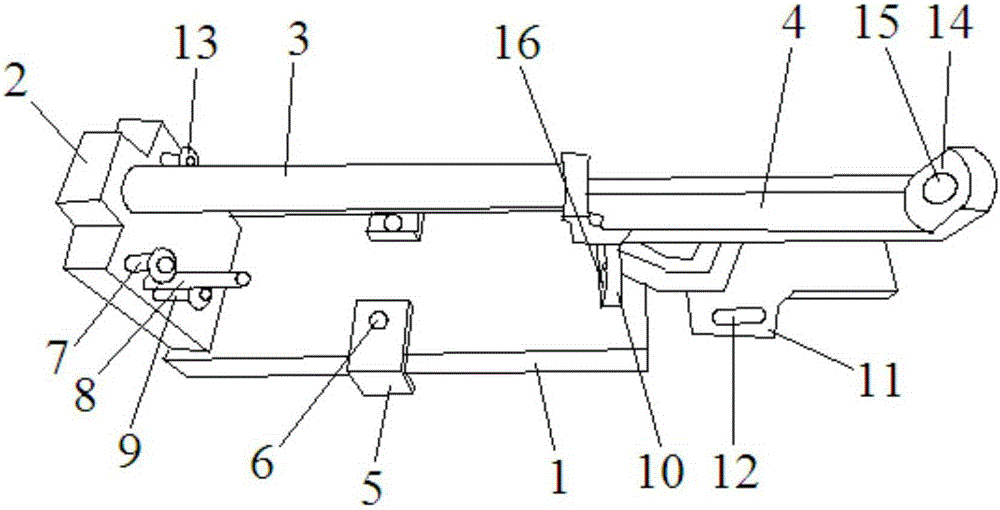

[0012] see figure 1 , a checker for detecting the processing size of the left, middle and right brackets, including a base 1, a support base 2, a cylindrical pass gauge 3 and a left, middle and right bracket 4, and the support base 2 is fixedly connected to one side of the base 1 and connected with it Vertically, the cylindrical through-gauge 3 is fixedly connected to the support base 2 and arranged horizontally, and the two sides of the middle part of the base 1 are respectively fixedly connected with L-shaped positioning seats 5, and the horizontal parts of the L-shaped positioning seats 5 are respectively provided with detection holes 6 , one side of the support seat 2 is respectively fixedly connected with upper, middle and lower positioning columns 7, 8, 9 arranged horizontally under the cylindrical general gauge 3; 3, the extension part 10 on the front end side of the left, middle and right bracket 4 is sleeved outside the middle positioning column 8, and the upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com