Liquid level controller

A technology of liquid level controller and float switch, which is applied in the direction of liquid level control, non-electric variable control, control/regulation system, etc. It can solve problems such as inability to install, long binding wire length, and limitations in pump control, and achieve reduction The effect of reducing volume, avoiding breakage, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

[0038] A. Overview.

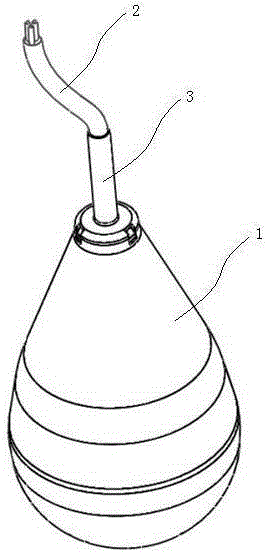

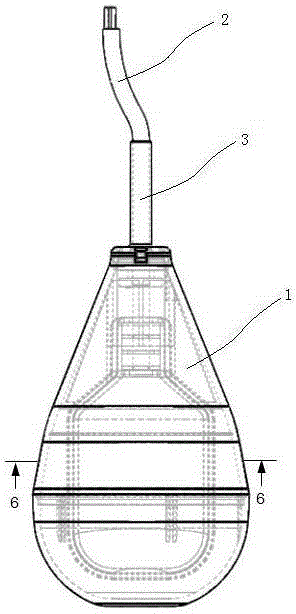

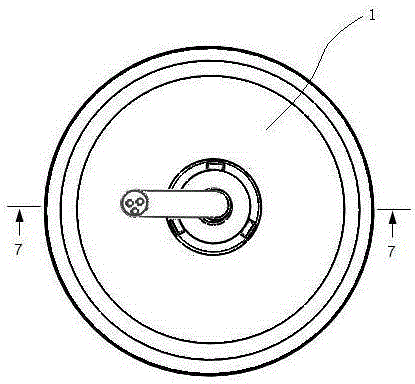

[0039] Turning now descriptively to the drawings, wherein like reference numerals represent like elements throughout the several views, Figures 1 to 11 A liquid level controller is described, including an outer casing 1, a float switch 7 built in the outer casing 1, and a sealing block and a counterweight 13 arranged in the outer casing 1 and surrounding the float switch 7.

[0040] B. Outer shell.

[0041] as attached Figures 1 to 4 As shown, the outer casing 1 is located on the outermost layer, and there is a cavity inside it for accommodating other components to obtain buoyancy in liquid, and prevent liquid or gas from entering the internal cavity to corrode the electrical components through sealing.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com