Open type transformer three-dimensional roll-core

A three-dimensional wound iron core and transformer technology, applied in the direction of transformer/inductor magnetic core, transformer/inductor parts, electrical components, etc., can solve the problems of difficult seam position processing, increased transformer loss, and inability to produce transformers. , to achieve the effect of small harmonics, improved lamination coefficient and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

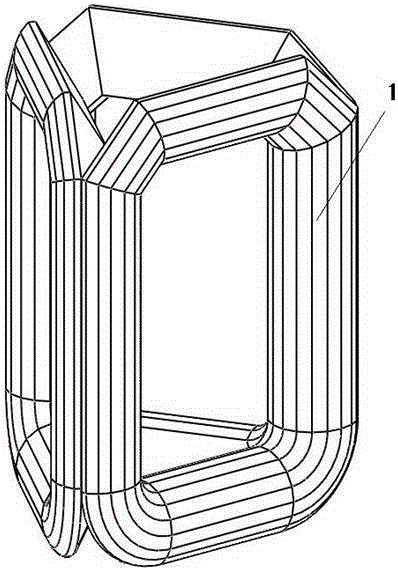

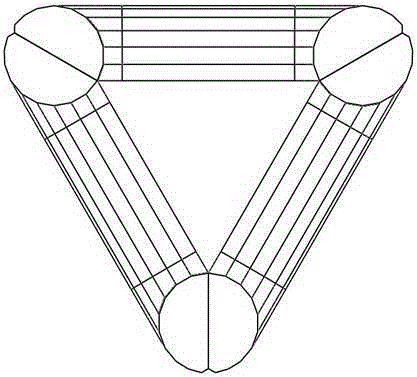

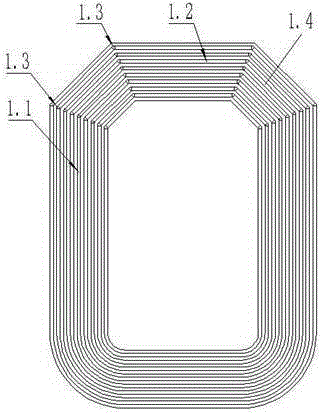

[0014] see figure 1 , which consists of three identical core frames 1 made of silicon steel sheets, see Figure 3-5 , each iron core frame 1 is composed of an upper half frame 1.2 and a lower half frame 1.1 to form a hexagonal frame. The hexagonal shape is formed by chamfering the two upper corners of the rectangular frame. It Including two iron core frame chamfering edges 1.4 in the upper left corner and upper right corner; the upper half frame has two left and right upper half frame chamfering edges 1.4.2, and the lower half frame has two left and right lower half frame chamfering edges 1.4.1, The silicon steel sheets of the two chamfered sides on the same side of the upper and lower half frames are arranged in a staggered manner. The silicon steel sheets of the two chamfered sides on the same side are inserted together to form the chamfered side 1.4 of the iron core frame. The connection of each layer of silicon steel sheets Seam 1.3 is at the bend of the silicon steel she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com