Equipotential operation method of tubular bus

A tubular bus, equipotential technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as development, and achieve the effect of improving the safety factor and facilitating command and monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

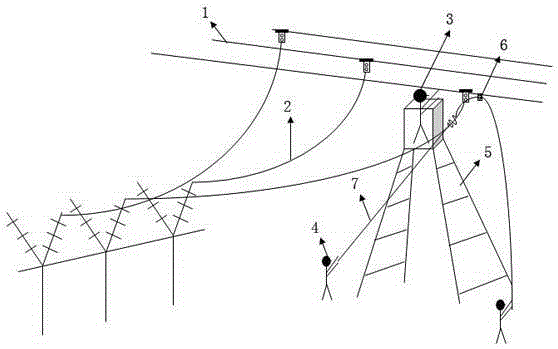

[0024] A method for equipotential operation of a tubular busbar, comprising the following steps:

[0025] Step 1. The ground potential electrician 4 sets up the insulating ladder 5 and hangs the protective rope. The ground potential electrician 4 installs the arc suppression block 6 on the magnesium-aluminum alloy tubular busbar 1 by using the insulating rod;

[0026] Step 2. After the equipotential electrician 3 puts on the shielding suit and conductive shoes, put the arc suppression rope 7 into the tool bag and put it on his back, and enter the electric field along the insulation ladder 5;

[0027] Step 3. The equipotential electrician 3 puts the arc-suppression rope 7 into the arc-suppression tackle 6, and tie one end of the arc-suppression rope 7 under the drain plate of the drainage line 2 that needs to be disconnected; then the ground potential electrician 4 cooperates to control the arc-suppression Rope 7, so that the two ends of the arc suppression rope 7 have tension;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com