Protective sleeve for steel pipe opening

A protective sleeve and nozzle technology, applied in the field of protective sleeves, can solve problems such as troubles of operation and maintenance workers, frictional damage to the insulation layer of wires or cables, AC or DC short circuits, etc., so as to reduce insulation damage and unsafe factors of hurting people. , Easy to install, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

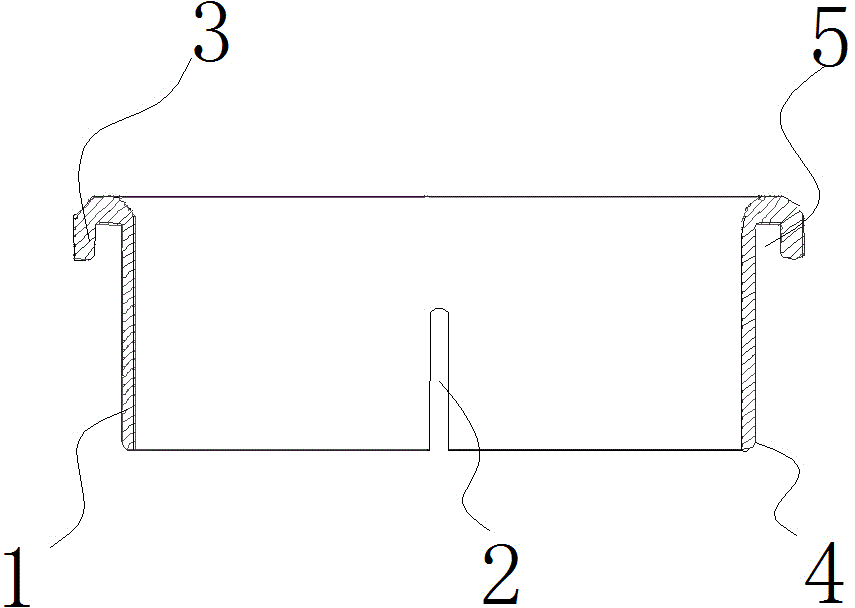

[0018] The protective sleeve for the steel pipe mouth of this embodiment, such as figure 1 As shown, it includes a protective sleeve 1 that can be inserted into the steel pipe. The outer diameter of the protective sleeve 1 matches the inner diameter of the steel pipe mouth. The end of the protective sleeve 1 away from the inserted steel pipe is folded outward to form a protective ring 3. Between the outer walls, a clamping ring port 5 is formed into which the peripheral wall of the steel pipe port can be inserted.

[0019] In order to effectively increase the tension between the steel pipe and the protective sleeve of the steel pipe mouth, the protective sleeve 1 is made of elastic material in this embodiment, the outer diameter of the protective sleeve 1 is larger than the inner diameter of the corresponding steel pipe mouth, and the protective sleeve 1 is inserted into the steel pipe at one end along the edge A plurality of shrinkage notches 2 are opened in the axial directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com