Nut retaining torsion control device of automatic line box body

A technology for fixing nuts and control devices, which is applied in the manufacture of tools, metal processing, metal processing equipment, etc., can solve the problems that the torque control device cannot be tightened, and the torque and speed of the nut cannot be uniformly controlled, so as to improve labor production efficiency , Simple structure, good tightening force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

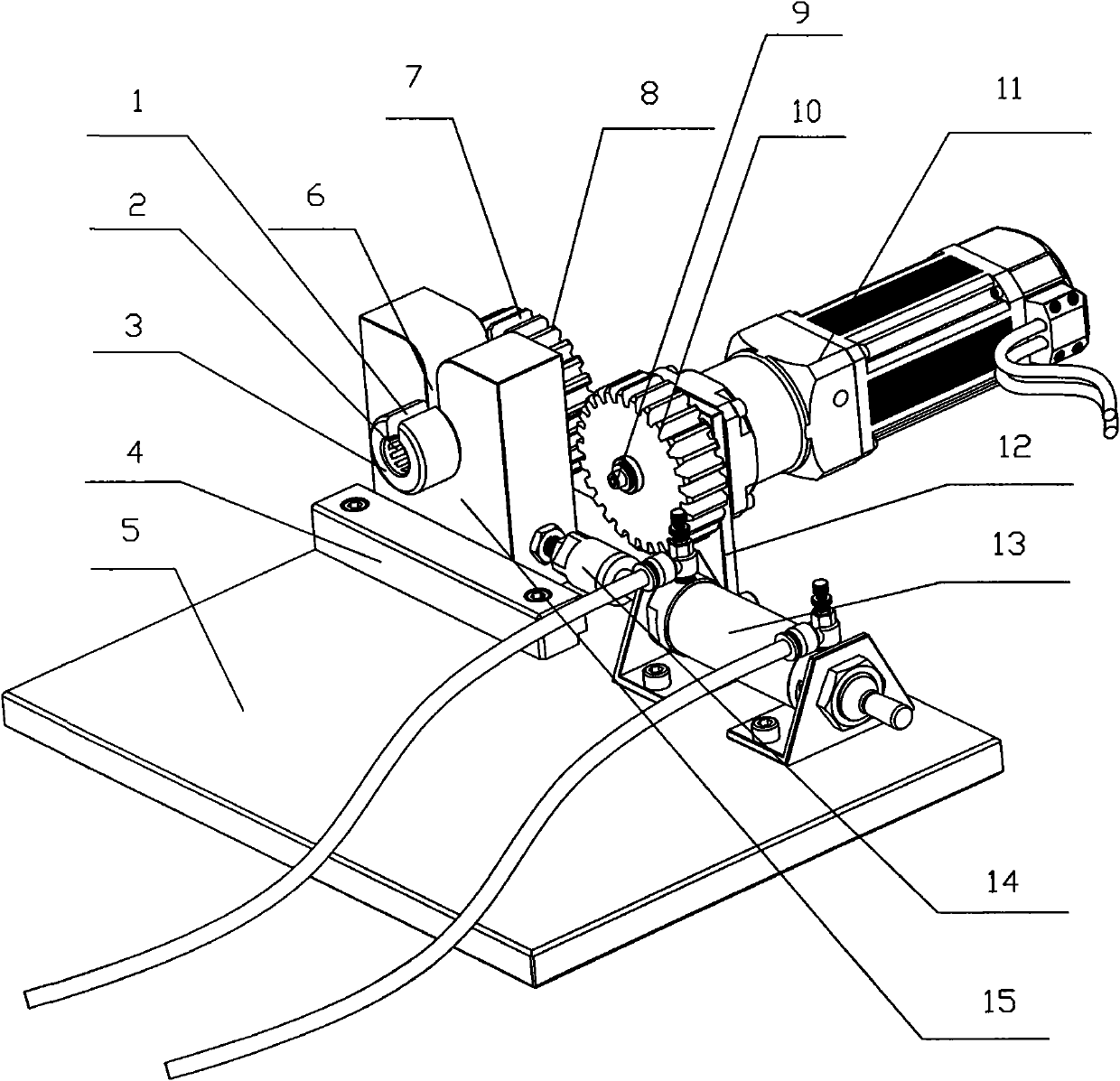

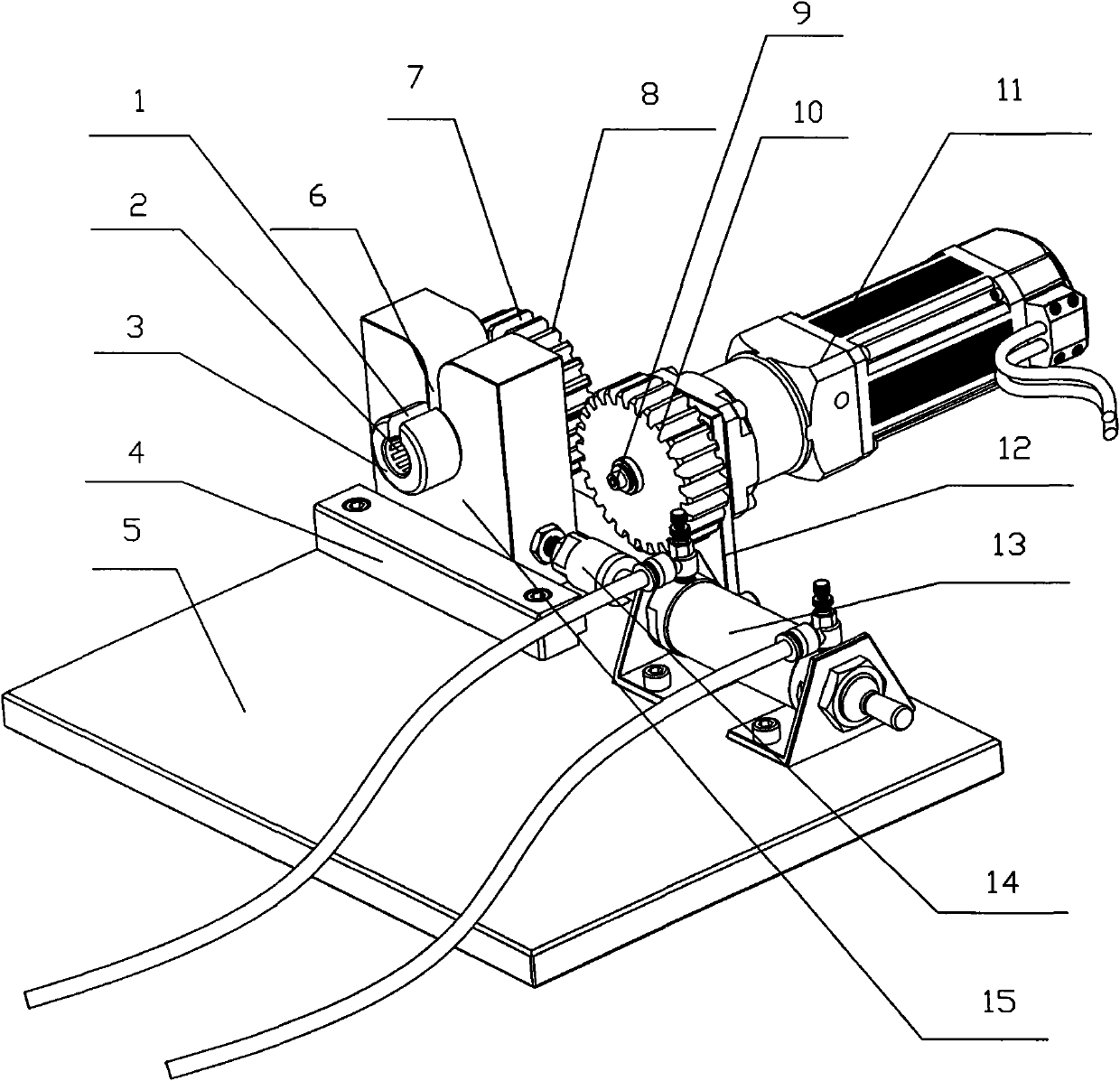

[0012] Such as figure 1 As shown, a fixed nut torque control device for an automatic box with wires includes a base 5 on which two fixed blocks 4 with a certain distance are arranged, and a sliding block 15 is slidably arranged between the two fixed blocks 4 Between, the two sides of the sliding block are respectively provided with a wrench 3 and a moving gear 8, and the moving gear 8 is connected with the wrench 3 to be able to rotate coaxially relative to the sliding block 15, and a nut is provided at the middle position of the wrench in the axial direction. Shaped mounting holes 2. The upper end face of the sliding block is provided with a notch 6 downwards, and notches 1 and 7 are also provided in the radial direction of the wrench and the gear. The gaps are located on the same straight line, and the width of the gap is slightly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com