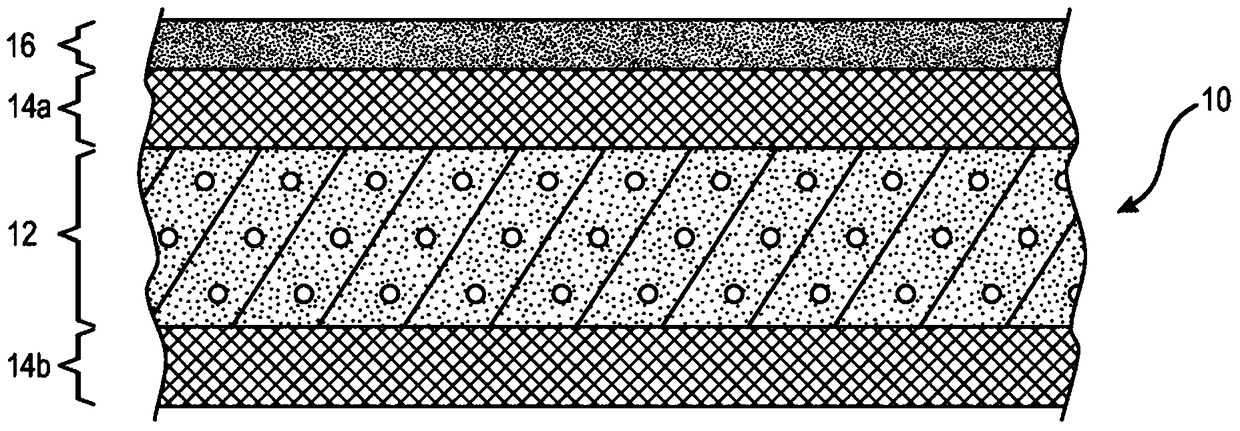

External jacket panel with integrated air/water barrier membrane

A technology of barrier films and panels, applied in the direction of floors, chemical instruments and methods, hydraulic material layered products, etc., can solve material errors, applicator errors, affecting the quality and durability of air/water barriers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0085] Fabrication of outer sheath panels with integrated air / water barrier membranes

[0086] Cementitious panels were prepared with a cementitious core comprising gypsum sandwiched between two fiberglass mats. Allow the cement panel to set.

[0087] The air / water barrier film was formulated with a polymeric binder, calcium carbonate, and antifungal as shown in Table 1. Spray cement panels with an air / water barrier film. A second control coated panel was prepared in parallel.

[0088] The first coated panel was conditioned in the oven at a first temperature zone at a temperature in the range of 100-140°F, then moved to a second temperature zone and further conditioned at a temperature in the range of 160 to 190°F.

[0089] A second control coated panel was conditioned in the same oven, but only in a second temperature zone at a temperature ranging from 160 to 190°F.

[0090] While the first coated panel was fully conditioned with no air bubbles and acquired anti-clogging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com