Filtering mechanism allowing filter paper to be conveniently laid

A technology of filter mechanism and filter paper, applied in fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve problems such as low efficiency, and achieve the effect of simple operation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

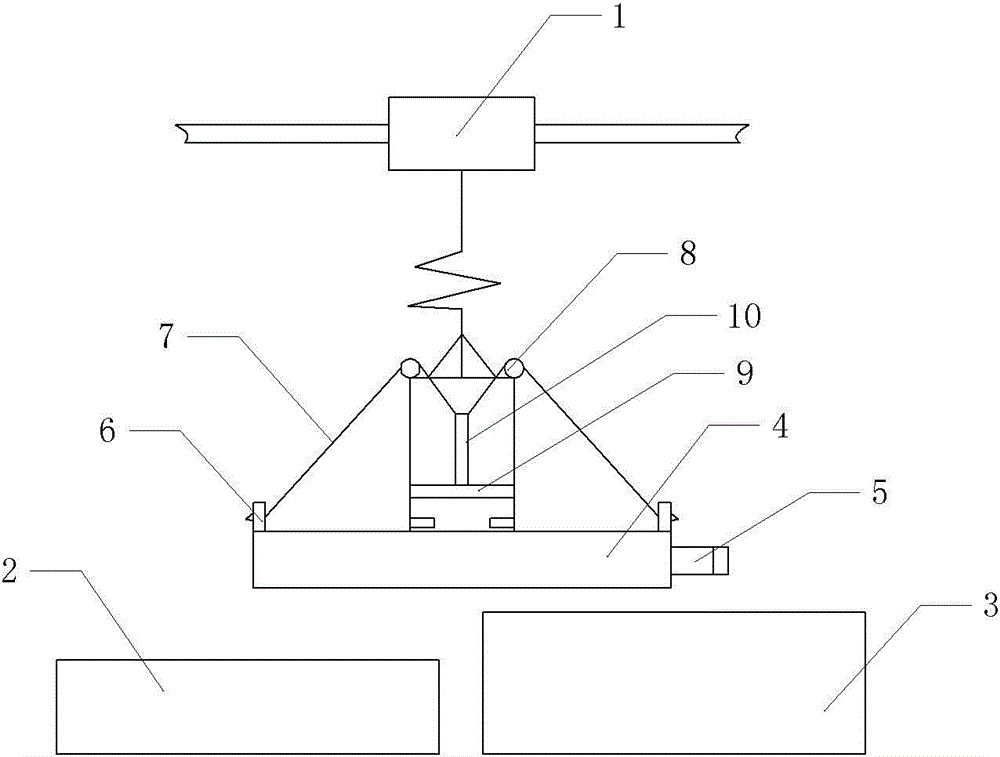

[0016] The reference numerals in the accompanying drawings of the description include: crane 1, filter paper table 2, filter tank 3, base plate 4, air pipe 5, hanging ring 6, chain 7, fixed pulley 8, piston 9, and force bar 10.

[0017] Such as figure 1 As shown, the filter mechanism that is convenient for laying filter paper includes a filter tank 3, and a filter paper platform 2 is arranged outside the filter tank 3. The area of the filter paper platform 2 is larger than that of the filter tank 3. 1. The suspension rope of the driving vehicle 1 is connected with a base column, and the lower end of the base column is connected with a base plate 4. Both the base column and the base plate 4 are hollow structures, and the two ends of the base column are connected, and the base column and the base plate 4 are connected. In addition, the base column The inner side is provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap