Continuous machining device for U-shaped heating pipes

A technology for processing equipment and heating pipes, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve problems such as low production efficiency, affecting processing efficiency, and processing continuity limitations, and achieve high processing efficiency and processing accuracy. High, well-designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

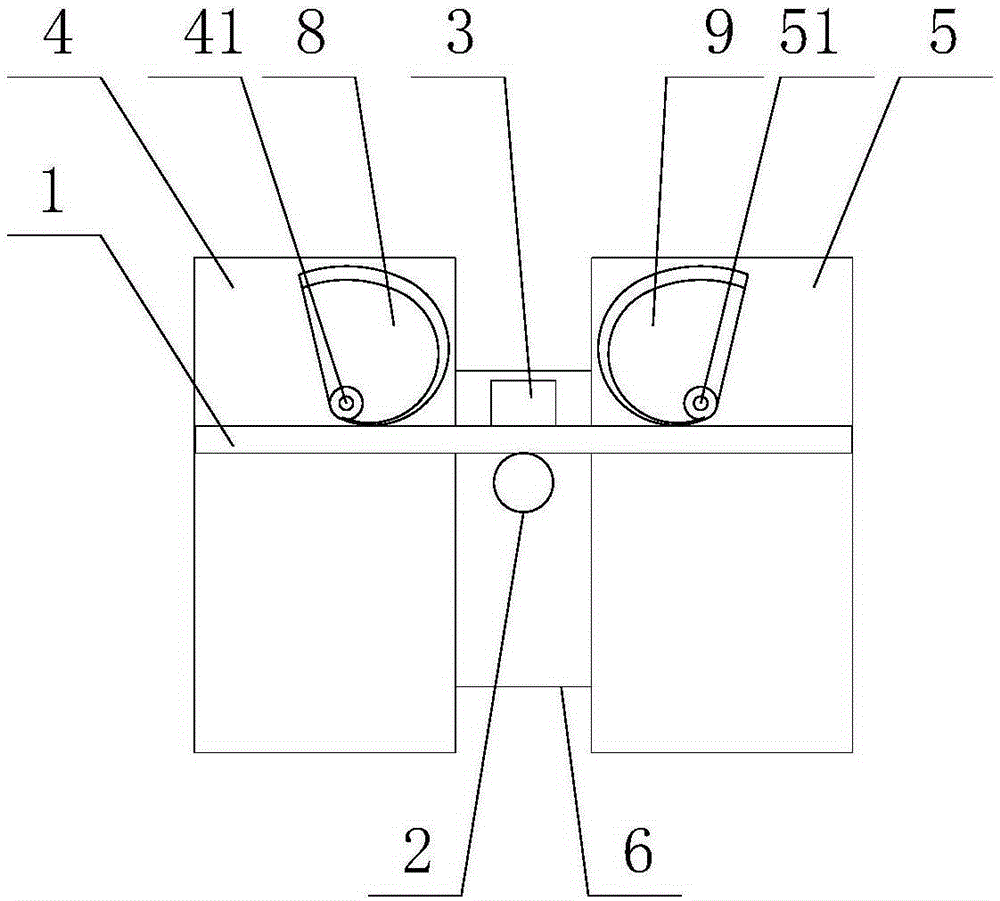

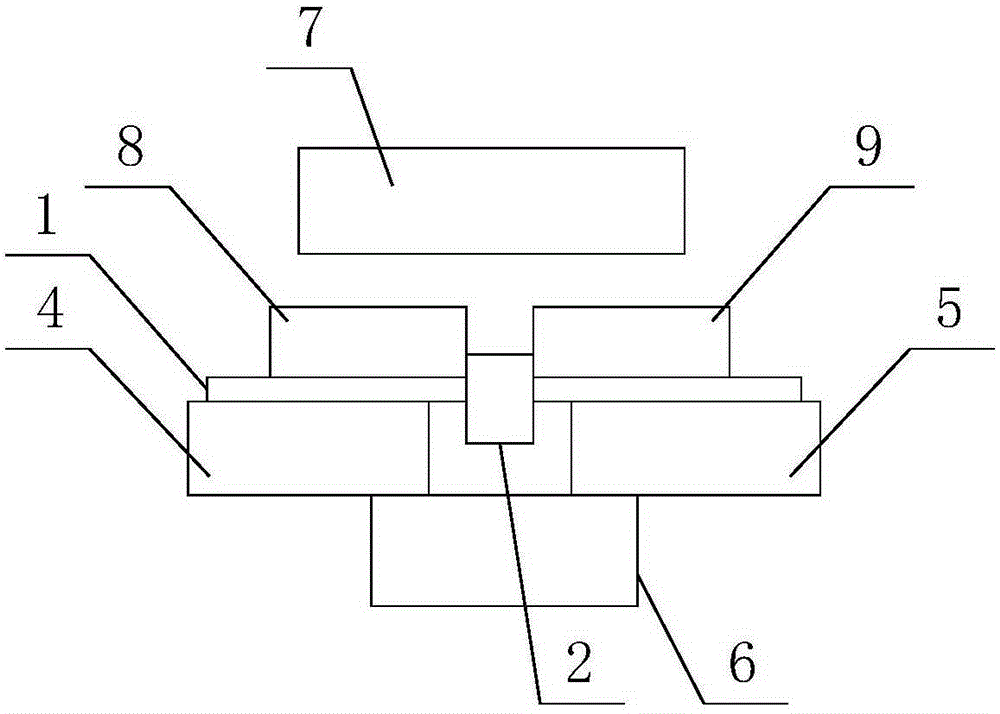

[0017] Such as figure 1 with 2 as shown, figure 1 with 2 It is a structural schematic diagram of a U-shaped heating tube continuous processing equipment proposed by the present invention, figure 2 for figure 1 Schematic diagram of the side view structure of the U-shaped heating tube continuous processing equipment.

[0018] refer to figure 1 with 2 , a U-shaped heating pipe continuous processing equipment proposed by the present invention is used for bending pipe 1, including: column 2, retaining column 3, first support platform 4, second support platform 5, material receiving trough 6, blanking Device 7, first rotary member 8, second rotary member 9, first drive device, second drive device;

[0019] The first support platform 4 and the second support platform 5 are arranged at intervals, and the two are respectively used to support the two ends of the pipe material 1 to be processed. A blanking channel is formed between the first support platform 4 and the second supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com