A processing method of high-density polyethylene winding structure wall pipe

A technology of high-density polyethylene and structural wall pipes, which is applied in the field of pipe processing, can solve the problems of high pipe base stability, difficulty in ensuring zero leakage, and low insertion accuracy, so as to save hot-melt materials and reduce costs , Dimensional accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0049] A processing method for a high-density polyethylene winding structure wall pipe, comprising the following steps:

[0050] (1). Prepare a continuous S-shaped electric heating wire with an electric heating wire processing device.

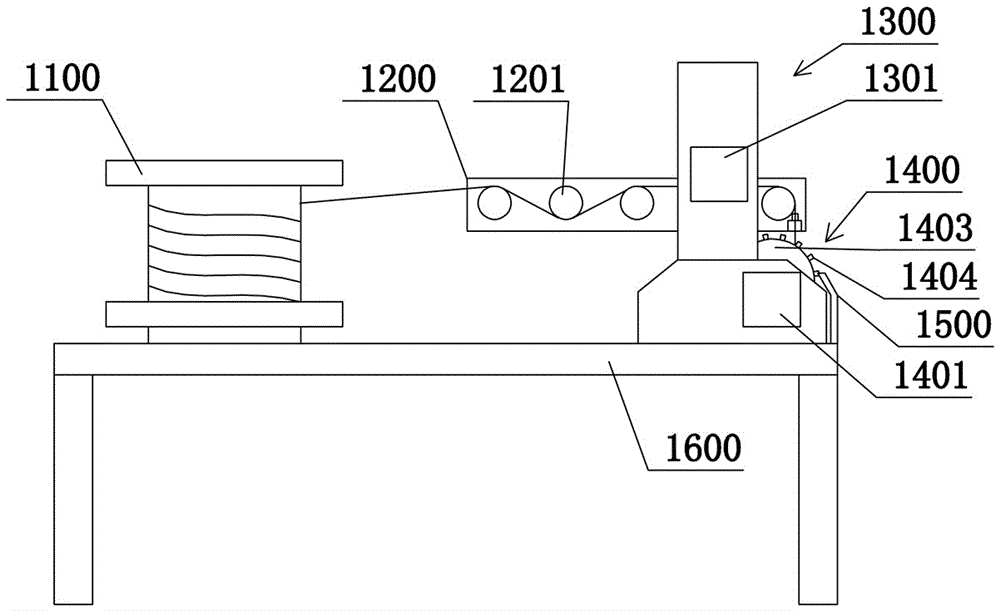

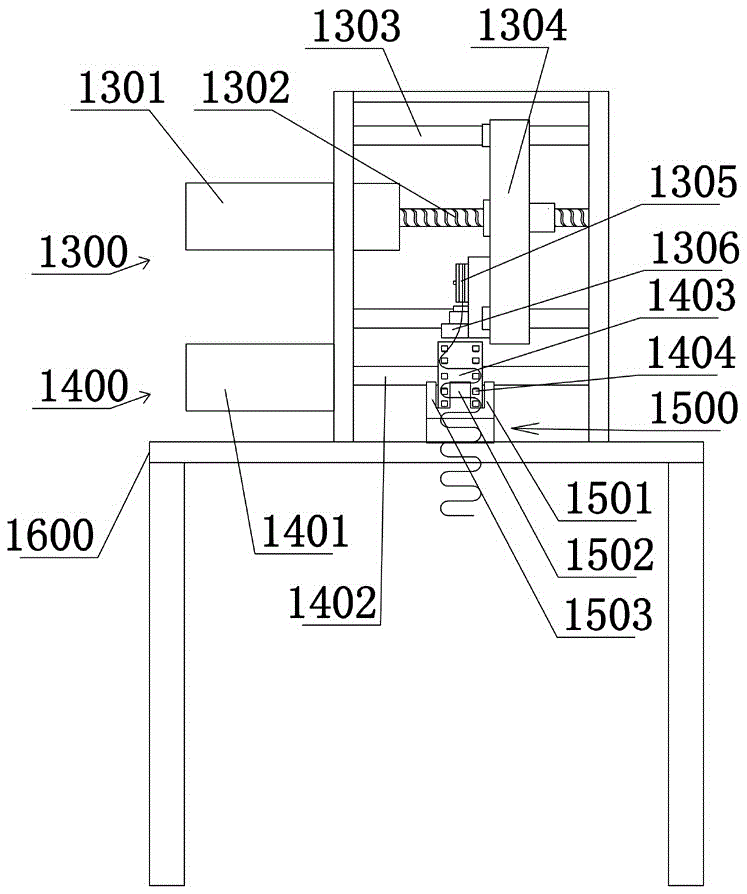

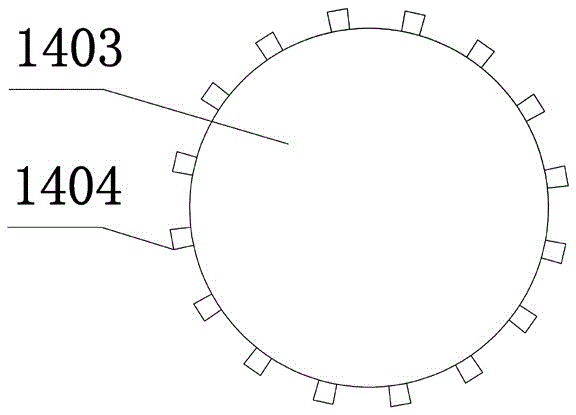

[0051] The electrothermal guide wire processing device includes a wire reel 1100 , a straightening mechanism 1200 , a wire guide mechanism 1300 , a wire bending mechanism 1400 , a shovel wire body 1500 and a frame 1600 .

[0052] The unprocessed electric heating wire is wound on the winding reel 1100 . The reel 1100 is rotatably connected with the frame 1600 . The electric heating guide wire enters the inlet end of the straightening mechanism 1200 from the winding reel 1100 .

[0053] The electrothermal guide wire is pulled and straightened by the straightening mechanism 1200 , and then input to the godet wheel 1305 . The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com