Parallel discharge multi-electrode wire carrying mechanism and balance discharge control method

A technology of electrode wire and multi-electrode, which is applied in the direction of electrode manufacturing, circuit, manufacturing tools, etc., can solve the problems of simultaneous multi-wire processing, high processing cost, and low efficiency, and achieve high-quality, high-efficiency processing capabilities and high performance The effect of price ratio and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings and specific embodiments.

[0034] Such as Figure 1-11 Shown.

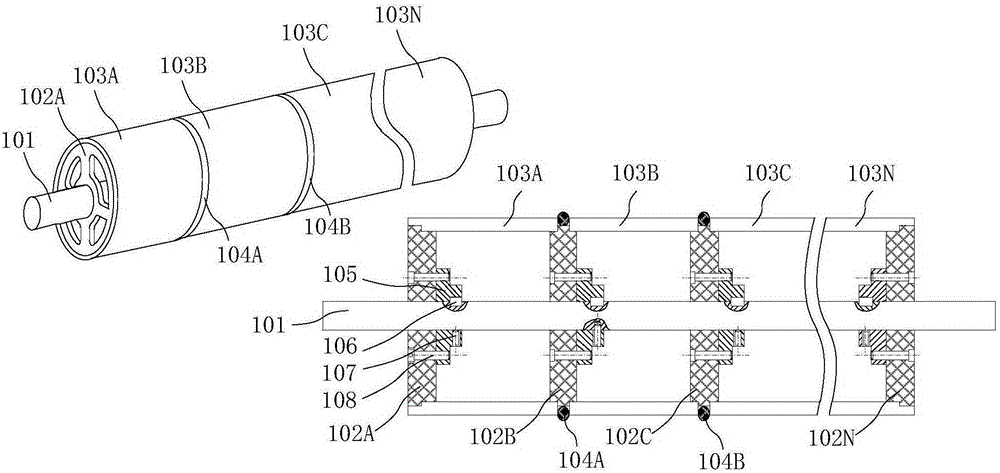

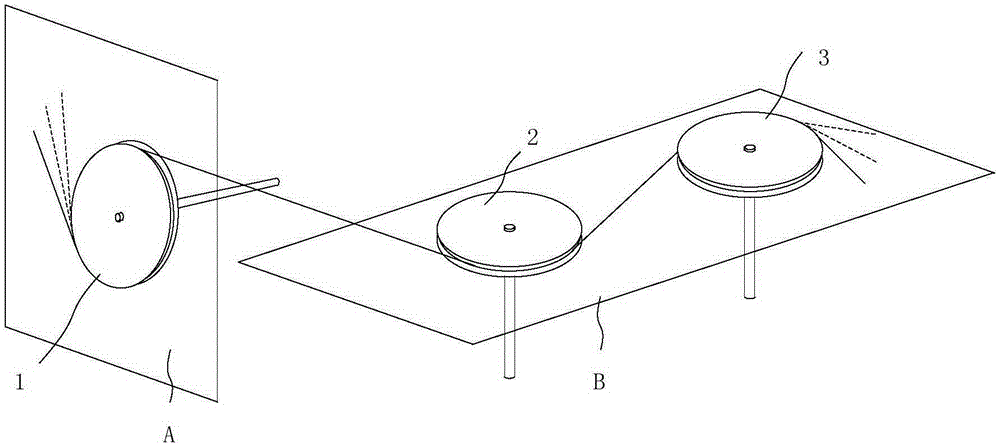

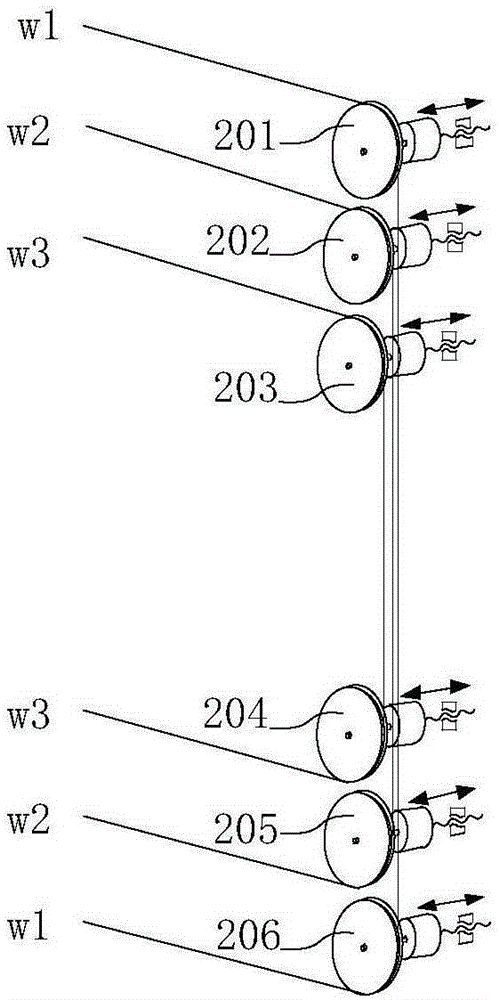

[0035] Different from the traditional wire EDM machine tool with only one wire electrode, the present invention adopts multiple wire electrodes and gathers all the wire electrodes closely at a certain interval through a multi-wire gathering cutting guide wheel group to form a group of parallel cutting wires. The electrode wires are physically insulated from each other, and each electrode wire is powered independently, thereby achieving parallel discharge and simultaneous cutting of multiple electrode wires. The wire storage tube (also known as the wire transport tube) is an important part of the wire EDM machine tool. In order to allow multiple electrode wires to run, take up and pay off simultaneously, the present invention is designed such as figure 1 Axial segmented wire storage drum shown. The wire storage cylinder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com