Collimation method of three-dimensional galvanometer and collimation system adopted by collimation method

A three-dimensional galvanometer and collimation technology, which is applied in the field of collimation systems, can solve the problems of adjusting the Z-axis galvanometer optical path center, Z-axis galvanometer center collimation difficulty and accuracy requirements, etc., to improve machining accuracy and ensure collimation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

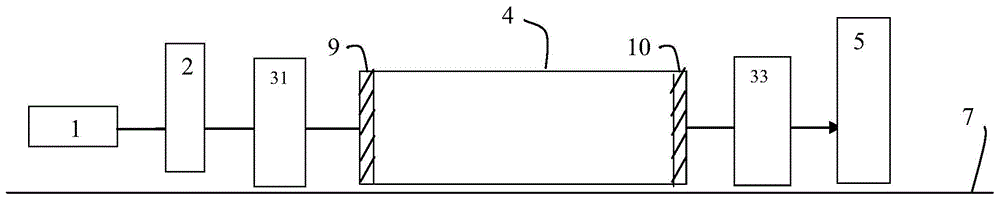

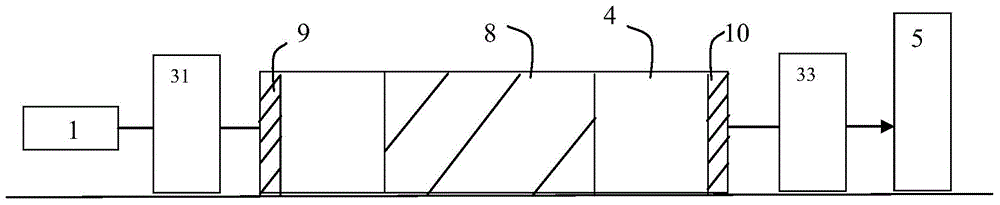

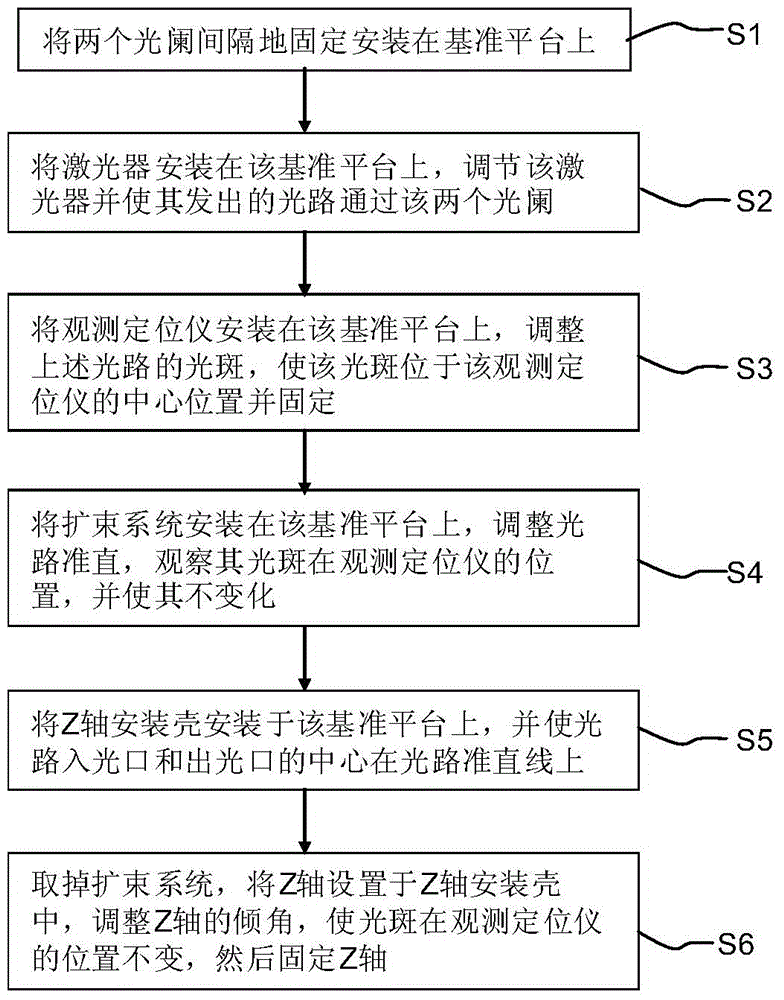

[0021] please participate figure 1 and figure 2 The collimation system of the three-dimensional vibrating mirror of the embodiment of the present invention includes a reference platform 7, a laser 1, a beam expander system 2, a first diaphragm 31, a Z-axis vibrating mirror mounting shell 4, a first Two diaphragms 33 and an observation locator 5 . The laser 1 and the beam expander system 2 are adjustably arranged on the reference platform 7 through a four-dimensional adjustment frame (not shown), and the beam expander system 2 is movably arranged on the reference platform 7 for debugging the installation of the Z-axis galvanometer Shell 4 is aligned. The first aperture 31 , the Z-axis galvanometer mounting case 4 , the second aperture 33 and the obser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com