Customizable shaping insole and manufacturing method thereof

A production method and technology for insole, which are applied to insoles, footwear, footwear, etc., can solve the problems of increased production cost, insole is difficult to fit, cannot be made, etc., to achieve the effect of balancing the body, reducing pressure, and wearing comfortably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

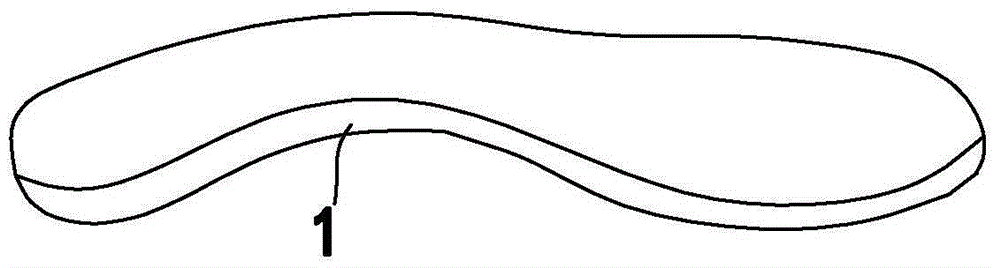

[0026] Such as figure 1 , Embodiment 1 of the present invention discloses a custom-made shaping insole, including a shaping layer 1, on which a concave-convex part suitable for the sole of a human body can be shaped according to the shape of each user's sole through a shaping mold. The shaping layer is a low-temperature thermoplastic plate that can be softened when heated, and can be shaped by cooling, and the molded concave and convex parts can be shaped. The outer surface of the shaping layer is also detachably covered with a layer of elastic surface layer that can deform with the deformation of the shaping layer by means of magic buckles and magic stickers. The elastic surface layer can be an elastic antibacterial textile layer such as nano-silver fiber, nano-carbon fiber, or the like. In this embodiment, the elastic antibacterial textile layer is an elastic antibacterial textile layer of nano-silver fibers.

[0027] In this embodiment, the composition ratio of the low-t...

Embodiment 2

[0039] Embodiment 2 of the present invention discloses a custom-made shaping insole, including a shaping layer 1, on which a concave-convex part suitable for the sole of a human body can be shaped according to the shape of each user's sole through a shaping mold. The shape layer is a low-temperature thermoplastic plate that can be softened and shaped when heated, and the molded concave-convex part can be shaped by cooling. The outer surface of the shaping layer 1 is detachably covered with an elastic surface layer which can deform with the deformation of the shaping layer. The elastic surface layer can be an elastic antibacterial textile layer such as nano-silver fiber, nano-carbon fiber, or the like. In this embodiment, the elastic antibacterial textile layer is an elastic antibacterial textile layer of nano-silver fibers.

[0040] In this embodiment, the composition ratio of the low-temperature thermoplastic plate is as follows: polycaprolactone 85kg, polyisoprene 15kg.

...

Embodiment 3

[0049] Embodiment 3 of the present invention discloses a custom-shaped insole, including a shaping layer, on which a concave-convex part suitable for the sole of a human body can be shaped according to the shape of each user's sole through a shaping mold, and the shaping layer The layer is a low-temperature thermoplastic plate that can be softened and shaped when heated, and the molded concave and convex parts can be shaped when cooled. The outer surface of the shaping layer 1 is detachably covered with an elastic surface layer which can deform with the deformation of the shaping layer. The elastic surface layer can be an elastic antibacterial textile layer such as nano-silver fiber, nano-carbon fiber, or the like. In this embodiment, the elastic antibacterial textile layer is an elastic antibacterial textile layer of nano-silver fibers.

[0050] In this embodiment, the composition ratio of the low-temperature thermoplastic plate is as follows: 75 kg of polycaprolactone, 15 k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com