Vibration type conveying device

A conveying device and vibrating technology, which is applied in the field of vibrating conveying devices, can solve problems such as inability to fully adjust the conveying speed of conveyed objects, difficult adjustment operations, and unstable vibration patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

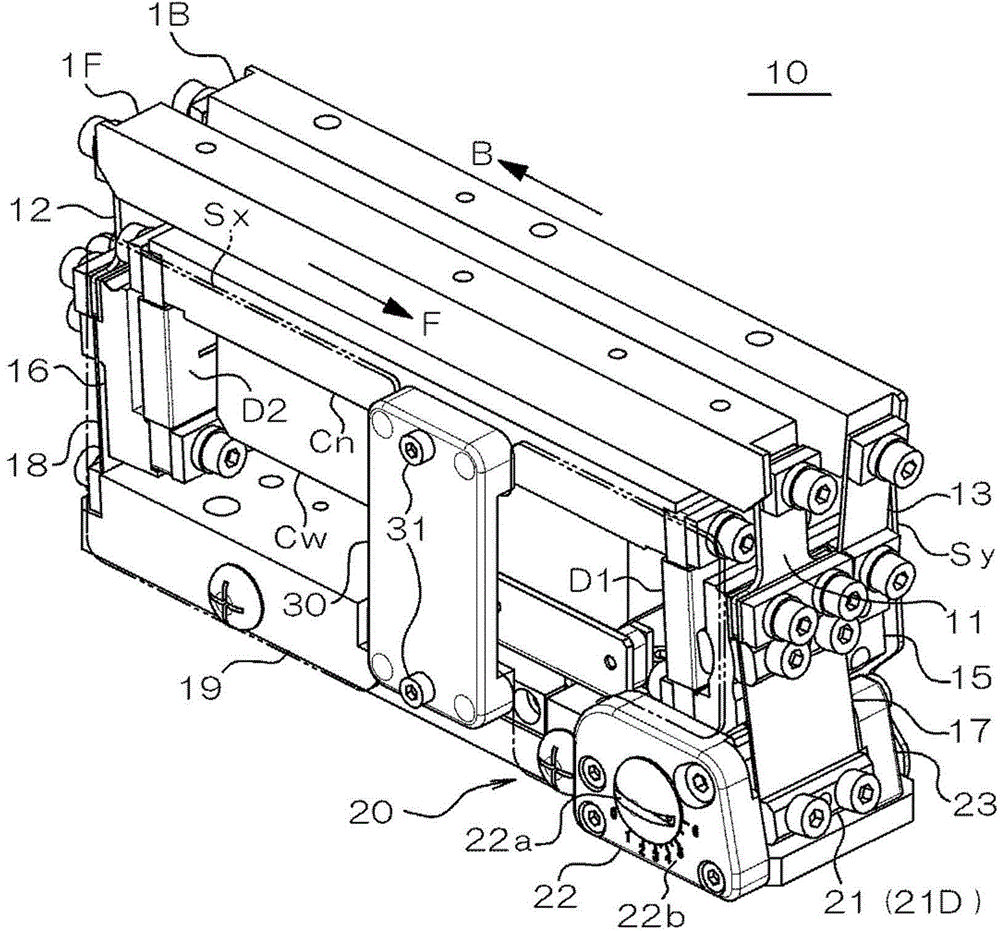

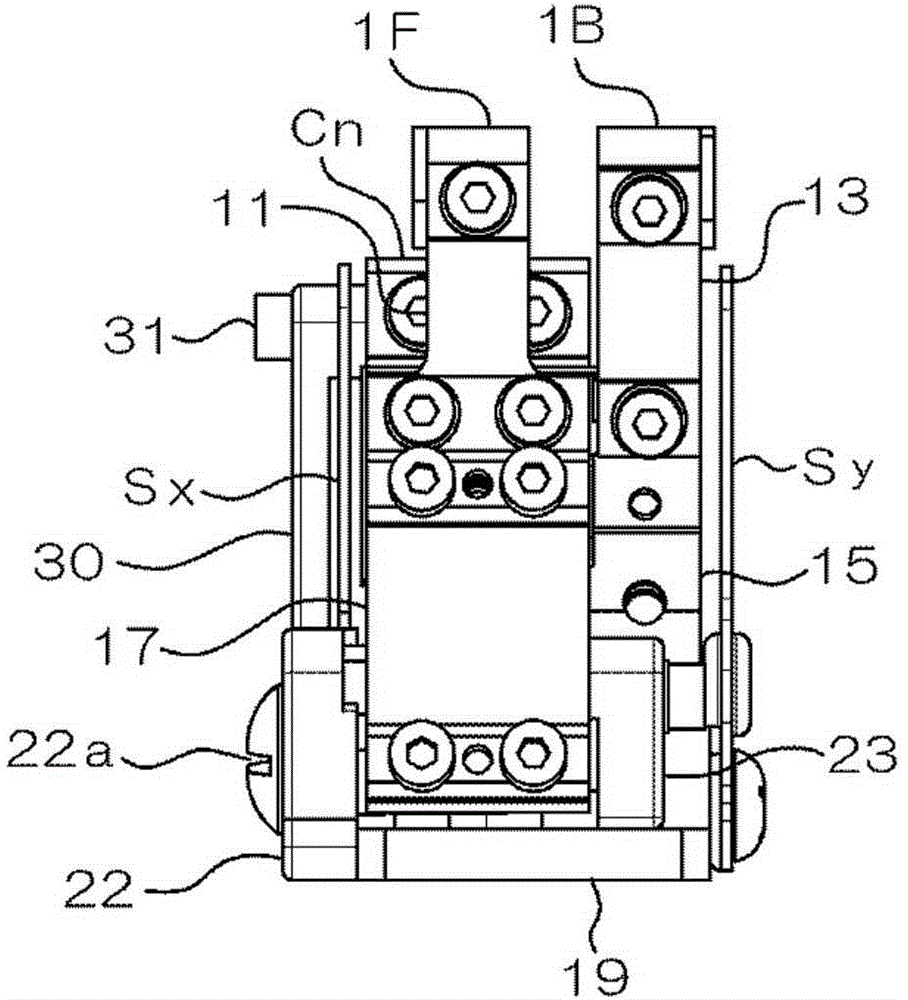

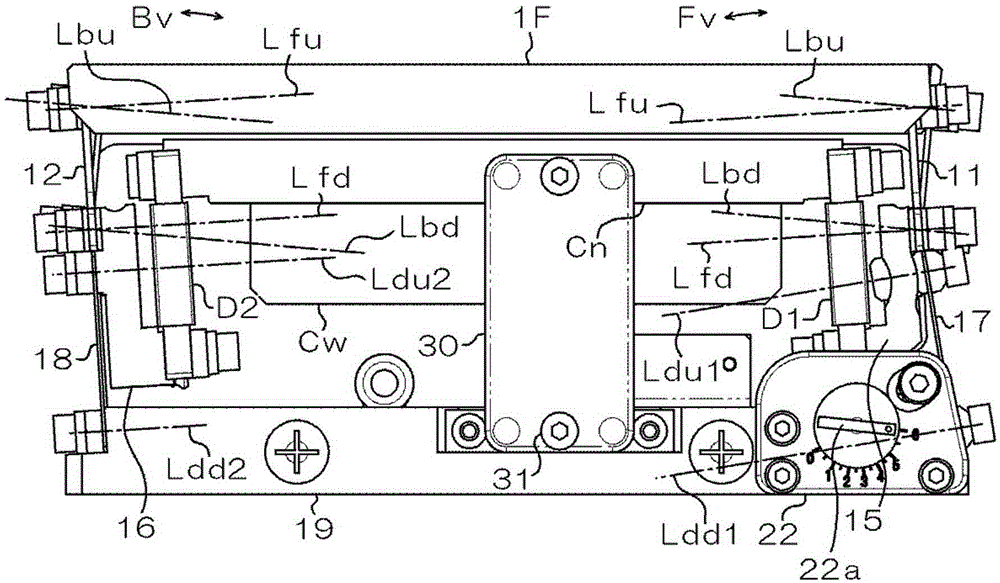

[0063] Next, embodiments of the present invention will be described in detail with reference to the drawings. figure 1 It is a perspective view of this embodiment, figure 2 is a front view of this embodiment, image 3 is a left side view showing the state with the side cover removed, Figure 4 It is a left side view showing the state after further removing the supporting and fixing parts, Figure 5 is another stereogram, Image 6 is a right side view showing the state with the side cover removed, Figure 7 is another perspective view with the side cover panels removed.

[0064] The vibratory conveying device 10 of the present embodiment can attach a conveying body (not shown) having a conveying path. The transport body has a groove-shaped transport path corresponding to the shape and size of the transport object (for example, an electronic device). In the illustrated example, the vibratory conveying device 10 has a first tank 1F and a second tank 1B, wherein a first con...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap