Double-aging heat treatment process for S520B material for low-temperature compressor

A technology of S520B and aging treatment, which is applied in the field of heat treatment process, can solve the problems of first pass and difficulty in guaranteeing mechanical properties, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

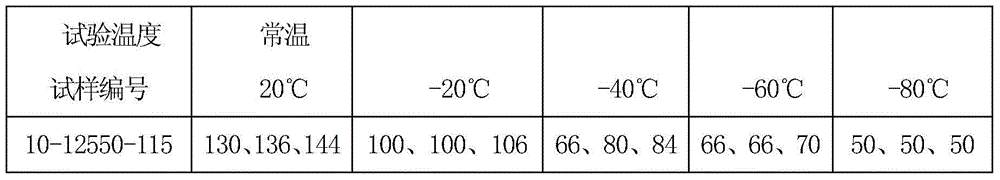

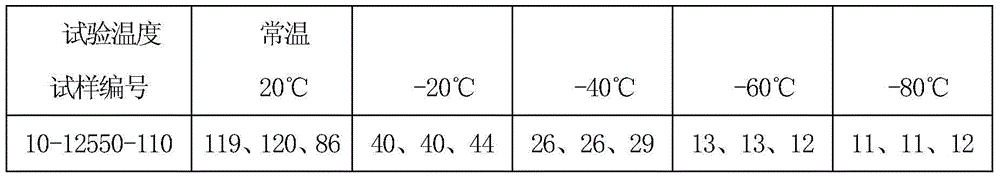

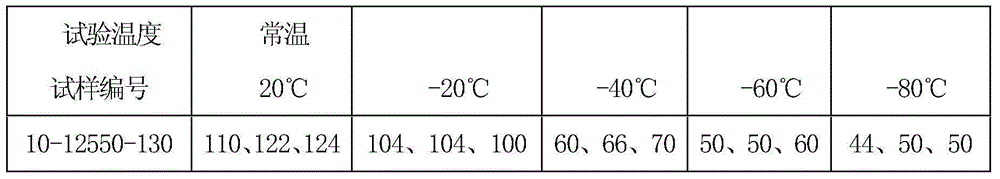

Examples

Embodiment 1

[0016] S520B material for cryogenic centrifugal compressor parts, its chemical composition: C: 0.031wt.%; Si: 0.31wt.%; Mn: 0.59wt.%; Cr: 15.41wt.%; Ni: 5.67wt.%; Mo: 0.73 wt.%; S: 0.003 wt.%; P: 0.021 wt.%; Nb: 0.37 wt.%; Cu: 1.34 wt.%; It is heat treated, including the following steps:

[0017] (1) Solution treatment, heat preservation at 1050°C for 2.0 hours, then oil (or water) cooling;

[0018] (2) Aging treatment, heat preservation at 610°C for 4 hours, then air cooling;

[0019] (3) For the S520B material after the aging treatment in step (2), a secondary aging treatment is added, that is, heat preservation at 610° C. for 4 hours, and then air cooling.

Embodiment 2

[0032] S520B material for cryogenic centrifugal compressor parts, its chemical composition: C: 0.031wt.%; Si: 0.31wt.%; Mn: 0.59wt.%; Cr: 15.41wt.%; Ni: 5.67wt.%; Mo: 0.73 wt.%; S: 0.003 wt.%; P: 0.021 wt.%; Nb: 0.37 wt.%; Cu: 1.34 wt.%; It is heat treated, including the following steps:

[0033] (1) Solution treatment, heat preservation at 1050°C for 3.0 hours, then oil (or water) cooling;

[0034] (2) Aging treatment, heat preservation at 590°C for 5 hours, then air cooling;

[0035] (3) For the S520B material after the aging treatment in step (2), a secondary aging treatment is added, that is, heat preservation at 590°C for 5 hours again, and then air cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com