A method for preparing the surface texture of super-oleophobic micropillar arrays

A micro-column array and surface texture technology, applied in the field of micro-texture, can solve the problems of poor surface mechanical properties, short service life, high efficiency, etc., and achieve the effect of easy and precise processing and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

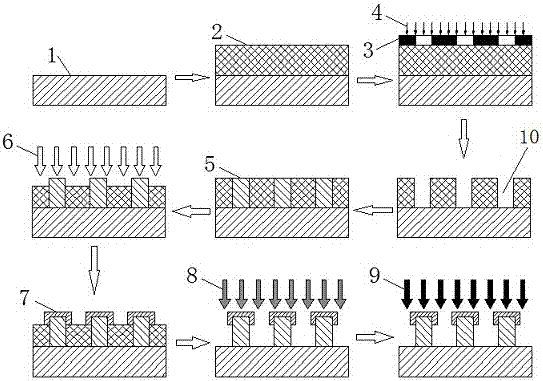

[0024] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

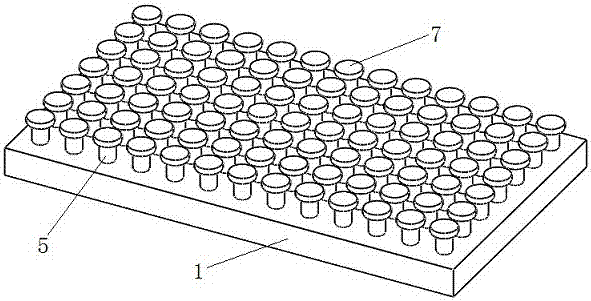

[0025] figure 1 The structure of each stage of the workpiece in the process of the present invention is shown. A method for preparing the surface texture of a super-oleophobic micropillar array of the present invention is used to construct a super-oleophobic surface texture on a metal substrate. The super-oleophobic The preparation method of the microcolumn array surface texture comprises the following steps:

[0026] S1. Clean and dry the metal base 1 to remove surface oil and impurities; make the surface of the metal base 1 clean, which is convenient for the subsequent texture component process, so that the texture and the metal base 1 are firmly connected.

[0027] S2. The photoresist is uniformly glued and prebaked. The photoresist is a positive glue, which is uniformly spin-coated on the positive surface of the metal substrate 1 through a glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com