Neutral salt electrolytic cell

An electrolytic cell and neutral salt technology, applied in the chemical field, can solve the problems of limited cell length, new process addition, large electrolytic cell length, etc., to avoid uneven concentration, good electrochemical reaction, and improve surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

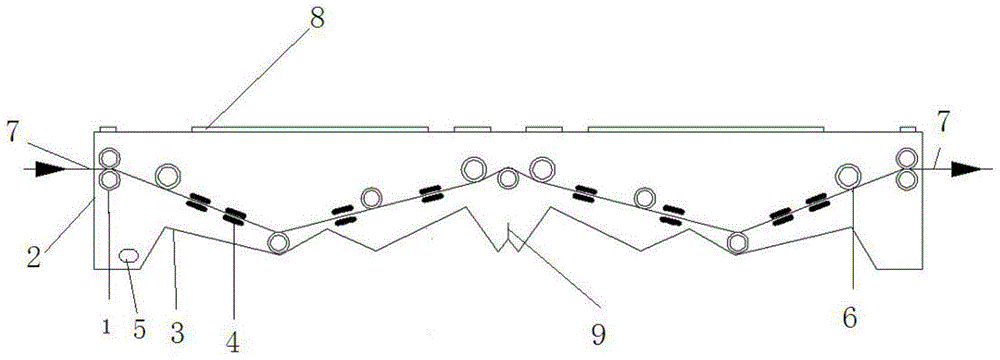

[0011] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, the present invention includes a tank body 2, a tank cover 8, squeezing rollers 1 are arranged on both sides of the tank body 2, a plurality of protrusions 3 are arranged at the bottom of the tank body 2, and a plurality of immersion rollers 6 are also arranged inside the tank body 2 , the immersion rollers 6 have different heights; the steel strip 7 is driven by the squeeze roller 1 to move along the immersion rollers 6; multiple electrode plates 4 are arranged on both sides of the steel strip 7, and the electrode plates 4 are connected to a power source.

[0012] The raised portion 3 is an irregular triangular pyramid.

[0013] The tank body 2 is divided into two parts along the moving direction of the steel belt 7, and a flow regulating plate 9 is arranged at the junction of the two parts.

[0014] The bottom plate of the tank body 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com