High-precision scraper paste control device

A high-precision, scraper technology, applied in the process of adding pulp raw materials, textiles and papermaking, fiber raw material processing, etc., can solve the limitation of the processing accuracy of the pulp control roller, the influence of the straightness of the pulp control roller, the wear of the anilox surface of the sizing roller, etc. problems, to avoid waste of paste, low cost, and avoid wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

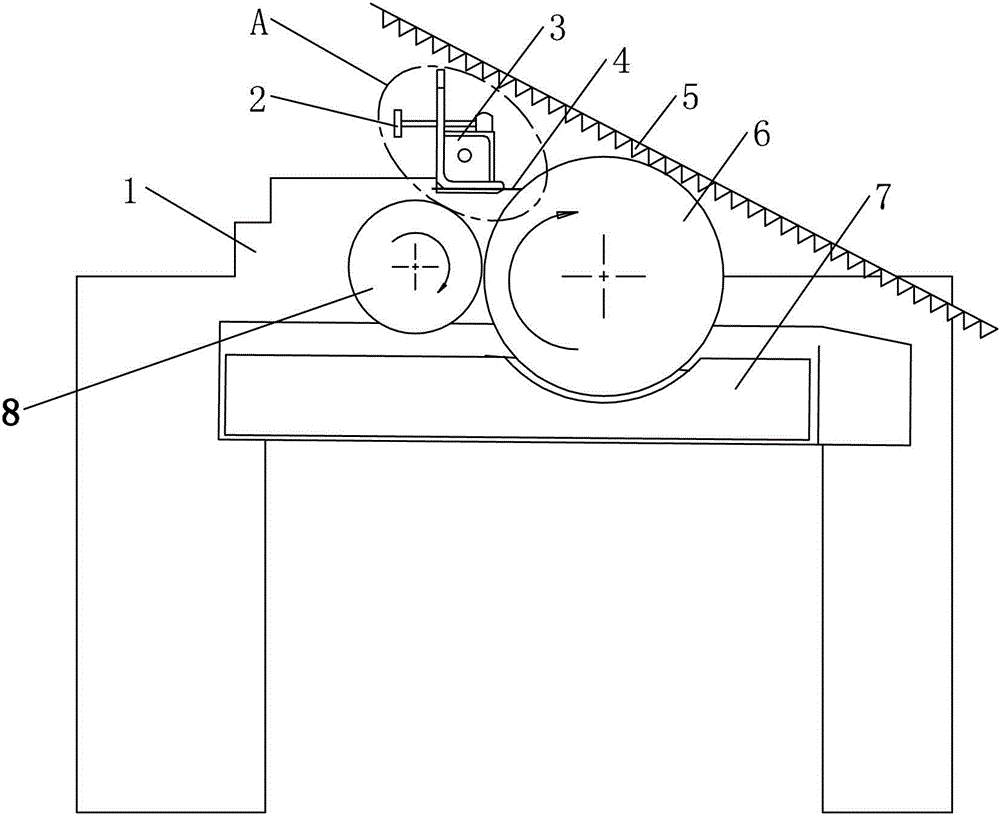

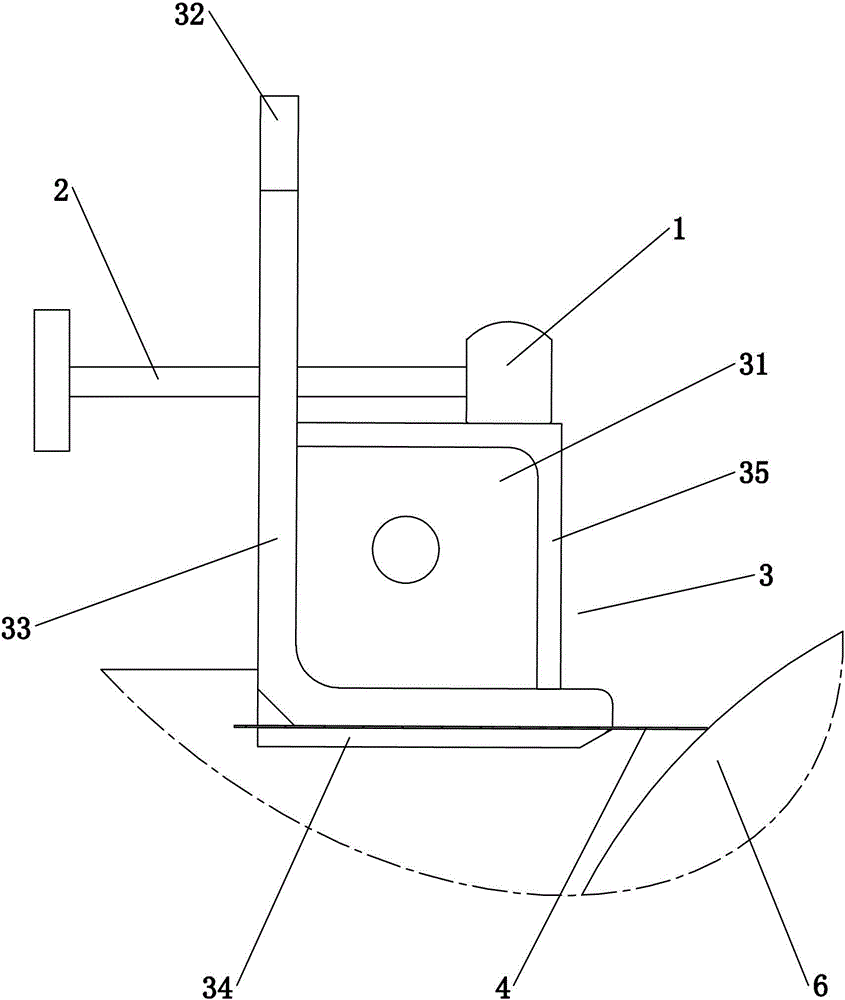

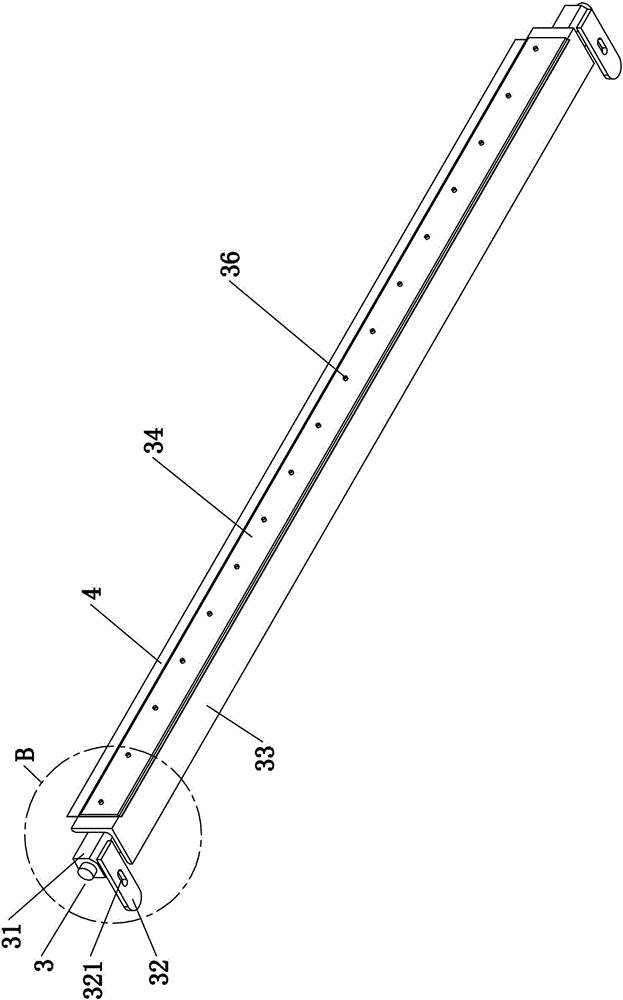

[0029] see figure 1 Shown, a kind of high-precision scraper pulp control device comprises a frame 1, a sizing roller 6 and a paste tank 7 for holding paste, and the sizing roller 6 is horizontally arranged on the frame 1 and connected with the frame 1 Cooperate with rotation, the paste tank 7 is arranged under the sizing roller 6, and the sizing roller 6 part is located in the paste tank 7, and the sizing roller 6 is provided with a squeegee blade 4, and the squeegee blade 4 extends along the axial direction of the sizing roller 6 , and can be adjusted on the frame 1, by adjusting the position of the squeegee sheet 4, the edge of the squeegee sheet 4 is close to or contacts the outer periphery of the sizing roller 6, so as to accurately scrape off the excess paste on the outer periphery of the sizing roller 6, To achieve the purpose of high-precision ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com