A method for rapidly manufacturing double-line round-end solid piers

A round-end, fast technology, applied in the direction of bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of unfavorable assembly line construction organization, difficulty in guaranteeing the quality of construction binding, and waste of construction time, so as to improve labor construction conditions and improve The degree of mechanization and labor productivity, the effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

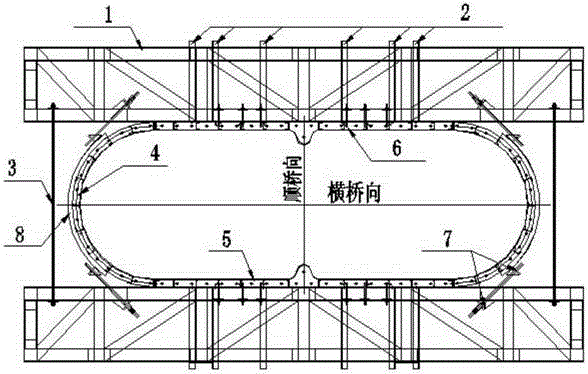

[0036] Such as Figure 1-6 Shown, the present invention is a kind of method for rapidly manufacturing double-wire round-end solid pier, which comprises the following steps:

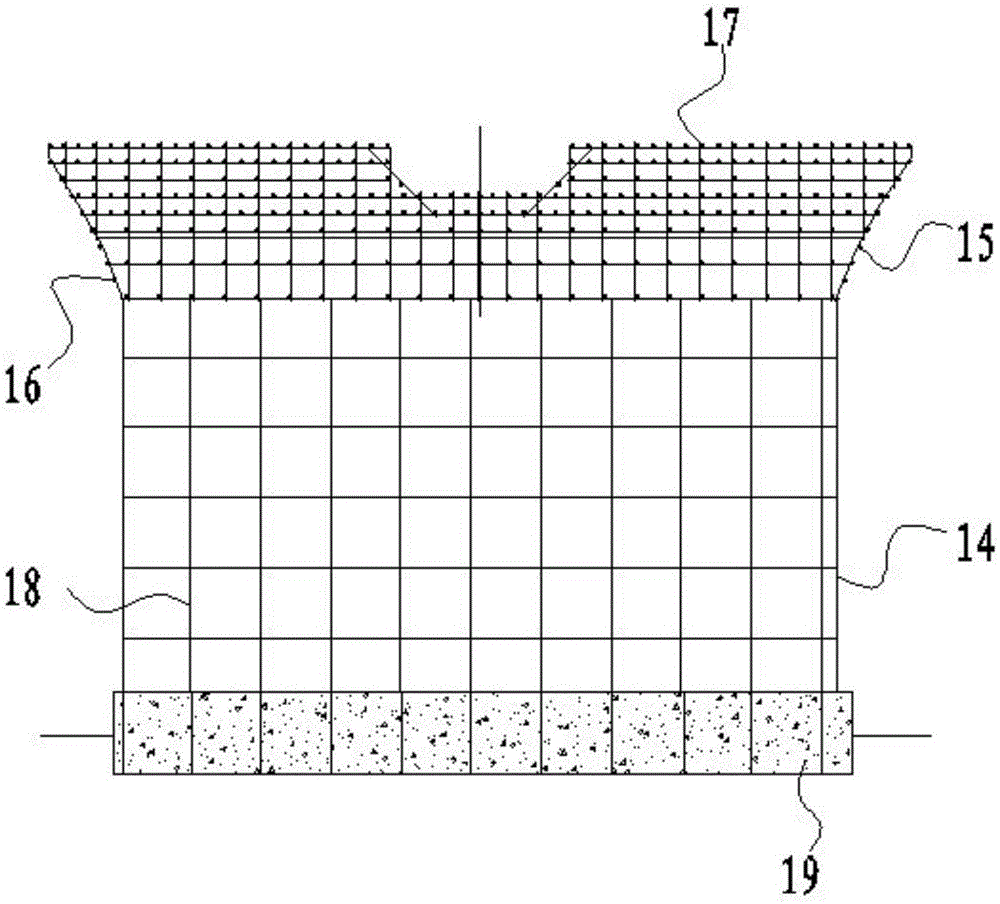

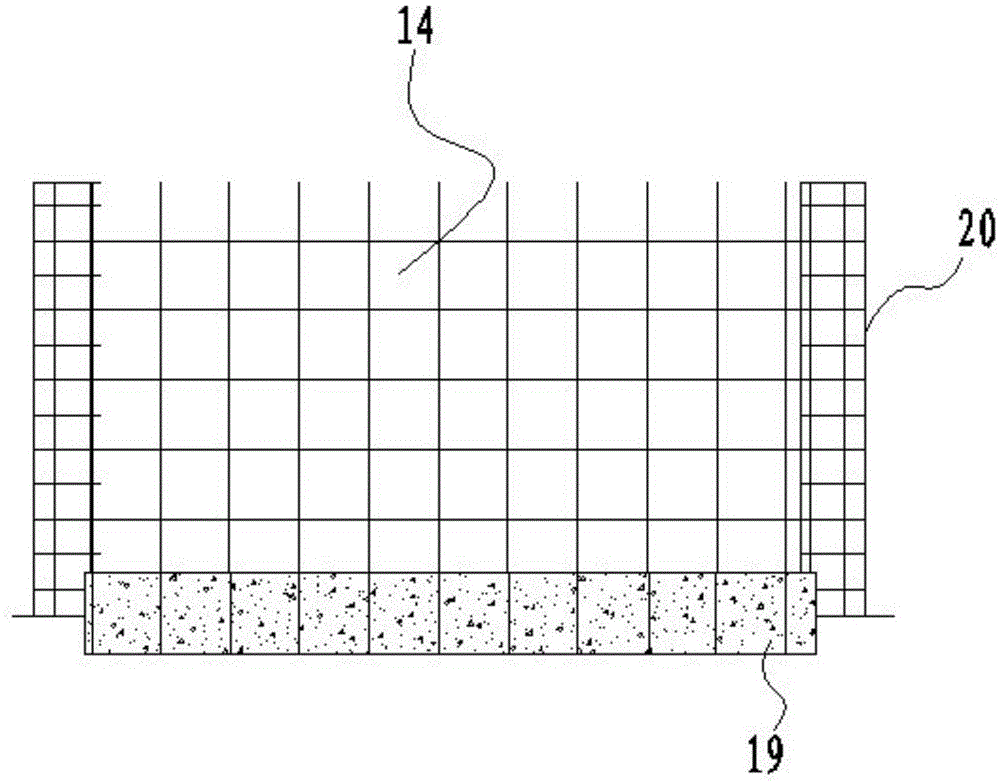

[0037] Step 1, pre-embedding pier body reinforcement: pre-bury the pier body vertical main reinforcement 18 on the cap 19 to form the pier body vertical reinforcement frame, and then pour concrete on the cap 19;

[0038] Step 2: Binding of steel bars on the pier body: after the concrete pouring of the cap 19 is completed for 10-12 hours and the strength is not less than 2.5Mpa, a pre-assembled outer frame 20 is erected around the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com