Electric welding factory building

A technology for workshops and workshops, applied in the field of new electric welding workshops, can solve the problems of easy dust, diffuse dust in the workshop, easy to run into animals such as mice and mosquitoes, etc., and achieve the effect of convenient disassembly and replacement and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

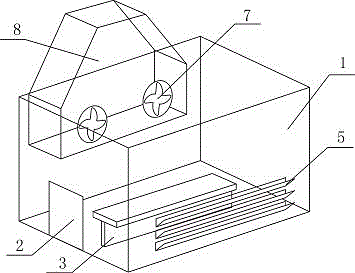

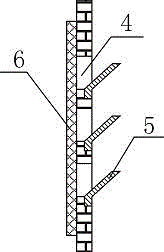

[0012] Embodiment 1: see figure 1 , figure 2 , a new type of electric welding workshop, including a cuboid workshop 1, the workshop 1 is airtight, and one end is provided with a hermetic door 2, the workshop 1 is opposite to two walls, the lower part of one wall is provided with an air inlet device, and the upper part of the other wall is An air outlet device is provided, and the air inlet device includes several strip-shaped air inlets 4, the air inlets 4 are arranged horizontally and distributed along the vertical direction, and each air inlet 4 is provided with a wind deflector 5, The wind deflector 5 is a vertical plate, the bottom of the vertical plate is detachably connected to the lower surface of the air inlet 4, the upper part of the vertical plate is inclined 45 to 60 degrees away from the workshop 1, and the air intake device is covered with a dust-proof gauze 6. The dust-proof gauze 6 is located inside the workshop 1 and is detachably connected to the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com