Oil temperature alarming star wheel external gearing four-division speed reducer of pile machine

An external meshing and four-shunt technology, which is applied in the direction of electromechanical devices, mechanical equipment, and control of mechanical energy, can solve the problems of loss of pressure balance inside and outside the box, difficulty in repair and maintenance, and small exhaust holes, so as to prevent oil leakage and reduce The effect of improving the probability of overturning accidents and carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

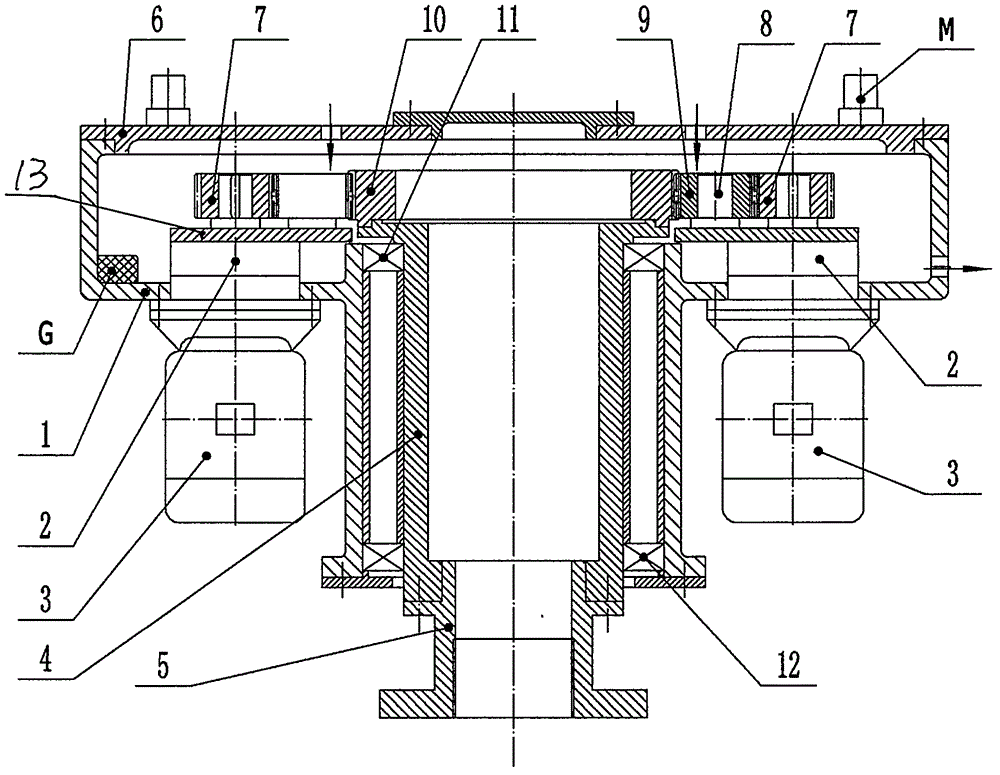

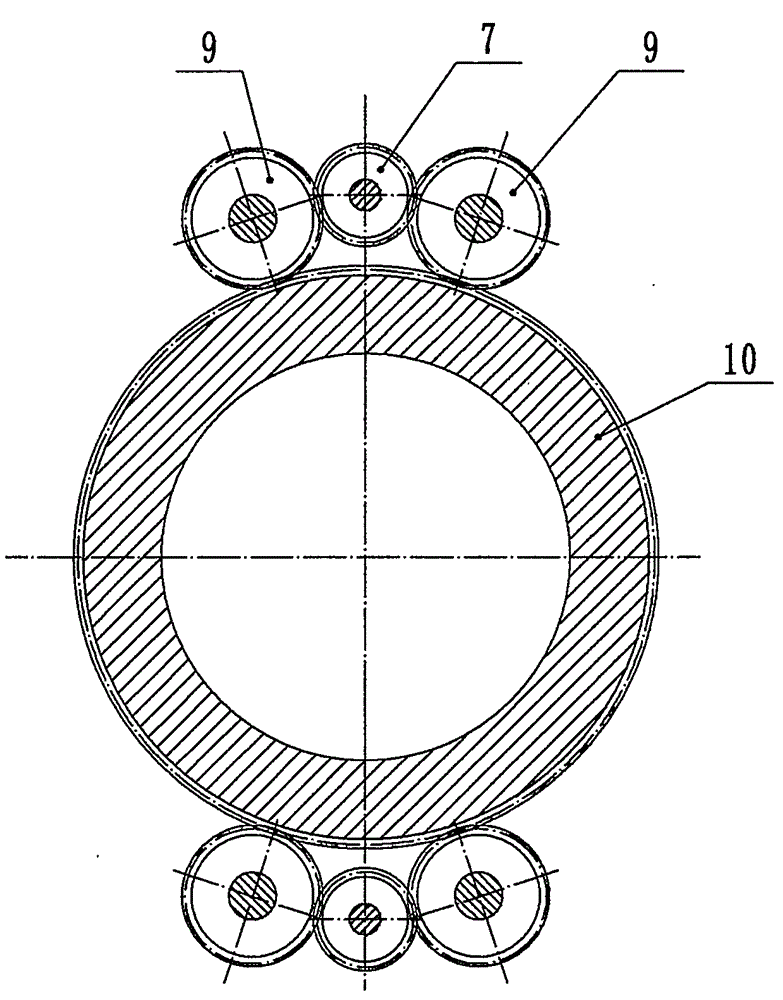

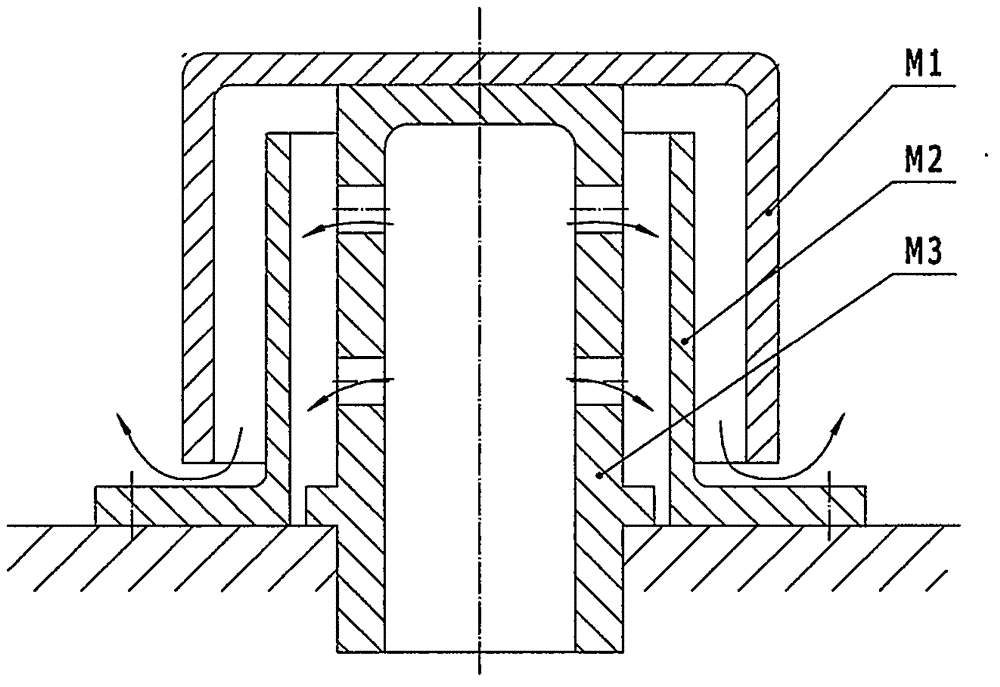

[0036] refer to figure 1 , 2 3. An oil temperature alarm star wheel meshing four-shunt pile driver reducer, including a box body 1, a motor 3 arranged symmetrically on both sides about the center, a cover plate 6 and an external meshing four-shunt transmission part placed in the box body 1 , characterized by:

[0037] Described box body 1 is provided with oil temperature sensor G, and oil temperature sensor G is like people's eyes clear, watches the change of oil temperature in the gear box of more than ten meters height all the time. The oil temperature is a very important factor for the normal operation of the reducer. This is because: the oil temperature will start to rise when the gear wears to a certain level; the oil temperature will start to rise when the bearing wears to a certain level; It starts to rise; bearing wear indicates that the lubricating oil is dirty, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com