Automatic-cleaning extractor hood and control method thereof

A technology of automatic cleaning and control method, which is applied in the fields of oil fume removal, heating method, and household heating, etc., can solve the problems of inaccurate testing, inconvenient use, and cumbersome user operation, and achieve the effect of convenient use and accurate detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

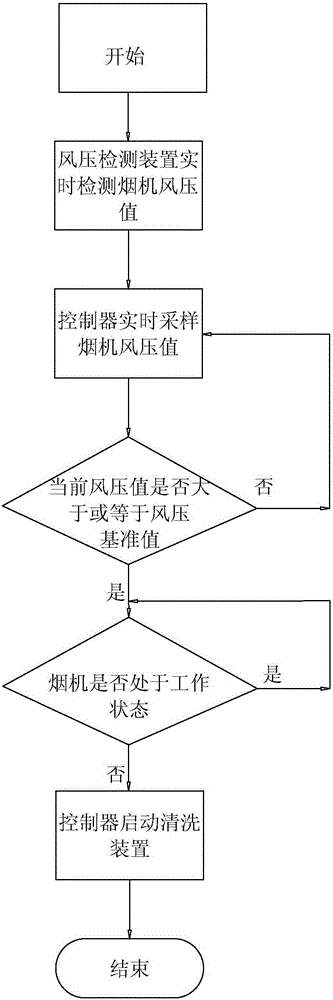

[0018] Specific implementation method: see figure 1 , the hood of the present invention includes a cleaning device, a controller, and a wind pressure detection device, and the cleaning device and the wind pressure detection device are all connected to the controller, and the described wind pressure detection device is used to detect Wind pressure, the controller is used to obtain the wind pressure parameter of the wind pressure detection device, and control the cleaning device to start when the wind pressure parameter is greater than or equal to a preset reference value.

[0019] When the filter screen is not blocked and the hood is working normally, the pressure in the wind cabinet should be a constant value, and this value is used as the wind pressure reference value of the system. With the continuous use of the range hood, a large amount of oil will be absorbed by the fan cabinet system and the oil grid of the range hood. At this time, the value of the wind pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com