High temperature and high pressure resistant visual reaction experiment apparatus

An experimental device, high temperature resistant technology, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of inability to observe and monitor the reaction process, inability to adjust the size of the container capacity, high price, etc., and achieve low cost. , easy processing, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

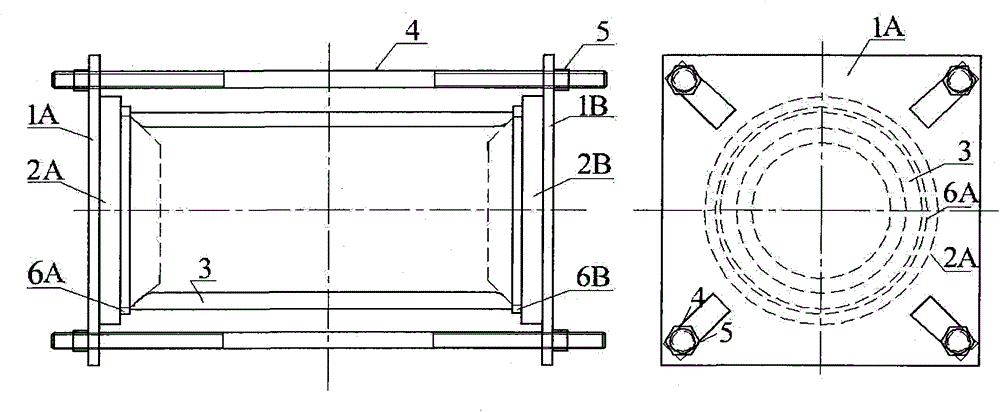

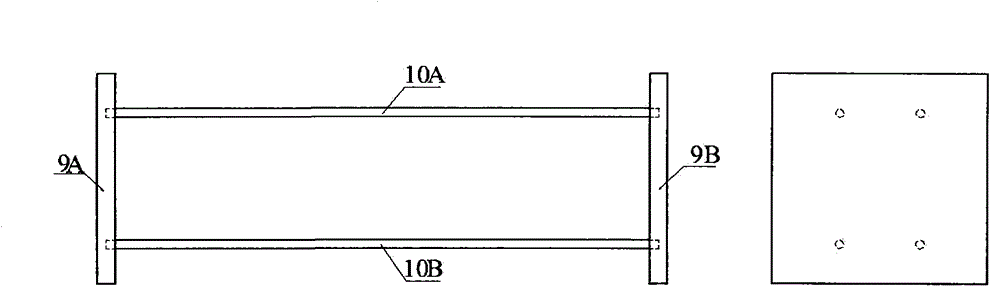

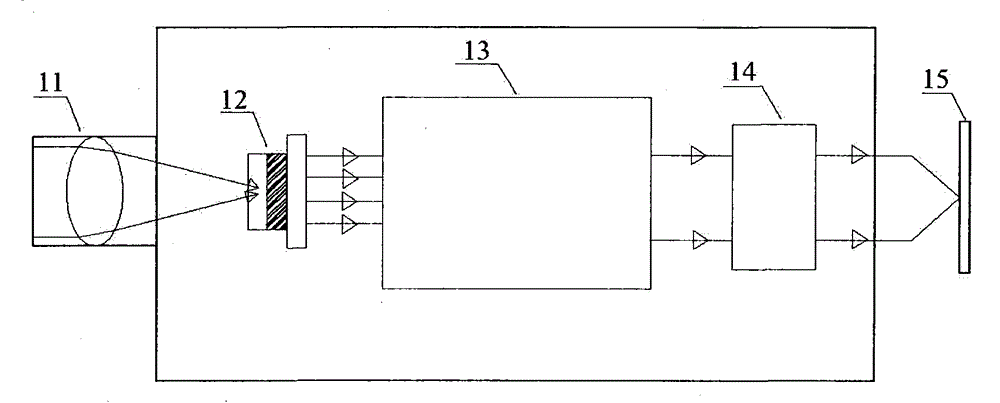

[0018] see figure 1 , the present invention includes: two ends ground quartz glass tube 3, ground quartz glass plugs 2A and 2B, polytetrafluoroethylene sealing rings 6A and 6B, stainless steel splints 1A and 1B, threaded stainless steel rods 4A, 4B, 4C at both ends and 4D, nuts 5A, 5A', 5B, 5B', 5C, 5C', 5D and 5D', sample holder 7, infrared thermal imager 8. Put the sample holder 7 with the sample into the ground quartz glass tube 3 at both ends; place Teflon sealing rings 6A and 6B at the two ports of the ground quartz glass tube 3 at both ends, and use ground quartz glass Plugs 2A and 2B plug the ground quartz glass tubes 3 at both ends and compress the Teflon sealing rings 6A and 6B; put two stainless steel splints 1A and 1B on the outside of the ground quartz glass plugs 2A and 2B respectively, and use two End with threaded steel rods 4A, 4B, 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com