Cutting frequency conversion control device and control method for cantilever coal mine roadheader

A technology of frequency conversion control and roadheader, applied in the direction of AC motor control, drive device, control system, etc., can solve the problems of increasing the ramp control time of the frequency converter, unfavorable for the heat dissipation of electrical components, and unfavorable for the installation of electrical components, etc. Realize the effect of renewable energy consumption, material cost saving and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

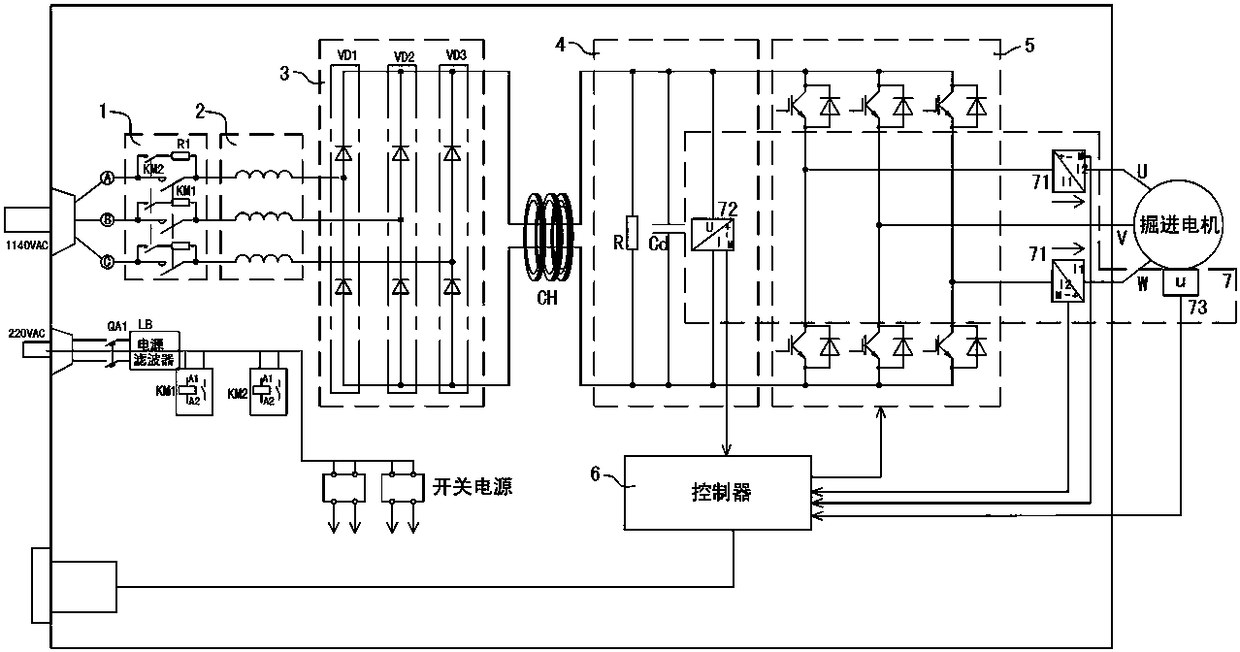

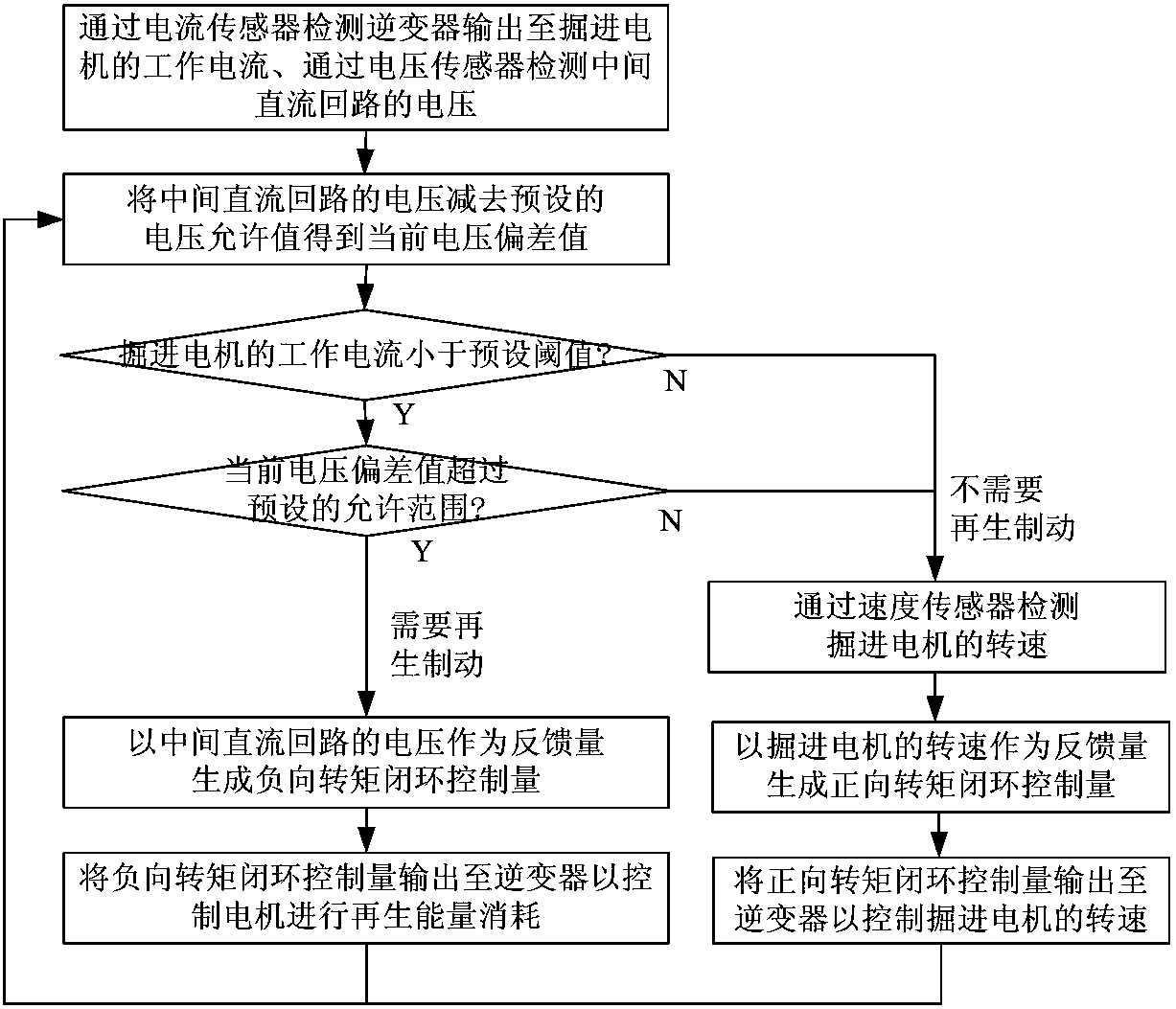

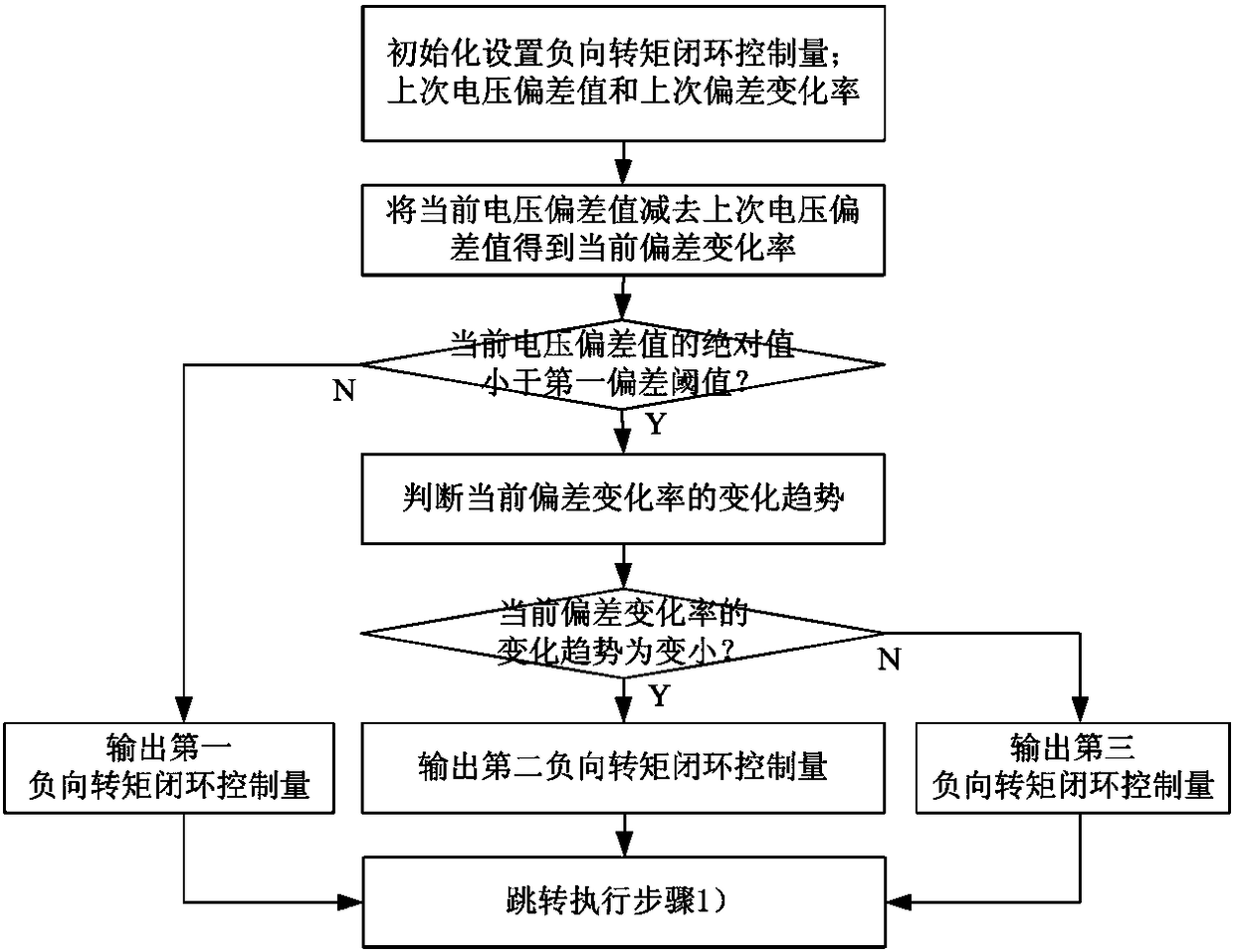

[0020] Such as figure 1 As shown, the cutting frequency conversion control device for the cantilever type coal mine roadheader in this embodiment includes a pre-charging and switching unit 1, an input reactor 2, a rectifier 3, an intermediate DC circuit 4, an inverter 5, a controller 6 and sensors Unit 7, the input end of the pre-charging and switching unit 1 is connected to the power supply, and the output end of the pre-charging and switching unit 1 sequentially passes through the input reactor 2, the rectifier 3, the intermediate DC circuit 4, and the inverter 5 to the cantilever coal mine roadheader The driving motor is powered, the sensor unit 7 includes a current sensor 71, a voltage sensor 72 and a speed sensor 73, the current sensor 71 is connected in series to the output end of the inverter 5, and the voltage sensor 72 is connected in parallel between the DC buses of the intermediate DC circuit 4 , the speed sensor 73 is installed on the output shaft of the driving mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com