Solar power station having battery panels capable of performing multi-degree-freedom movement

A degree of freedom and battery panel technology, applied in the field of solar power stations, can solve the problems of low solar energy utilization rate and poor flexibility of solar panels, and achieve the effect of flexible and free tilting range, compact structure and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

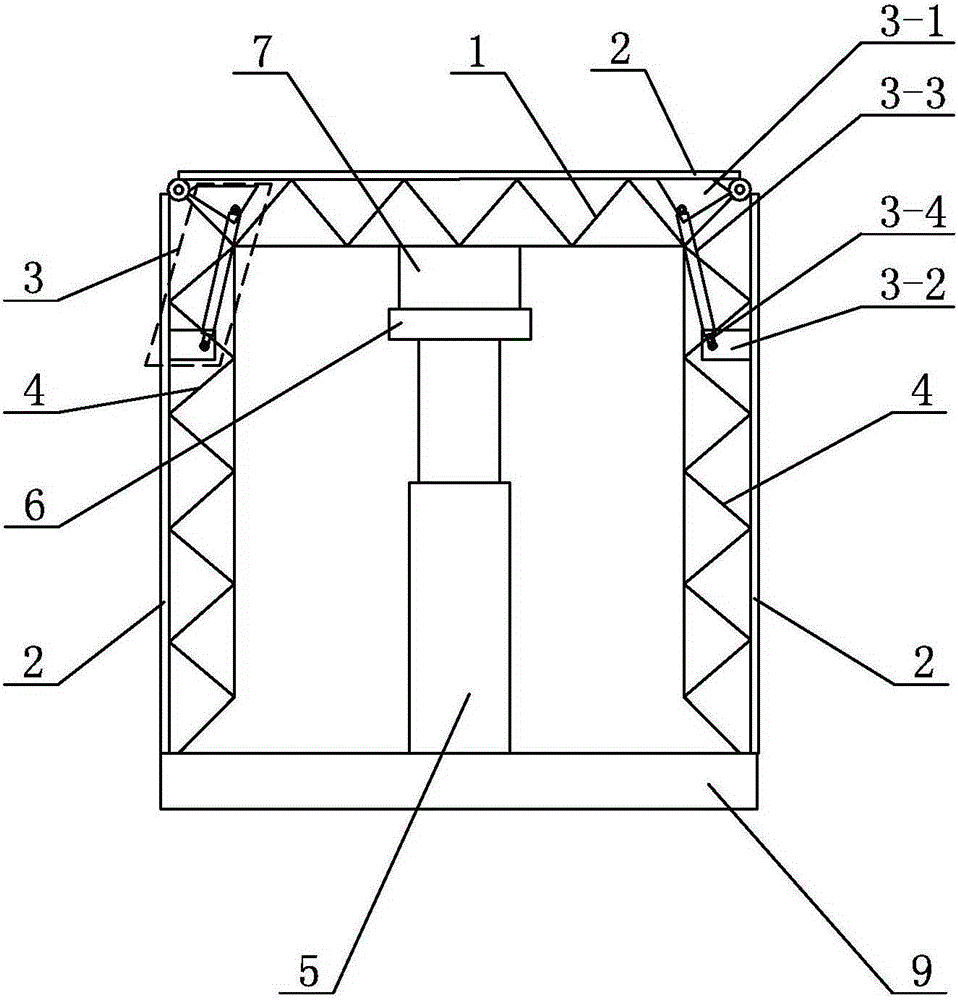

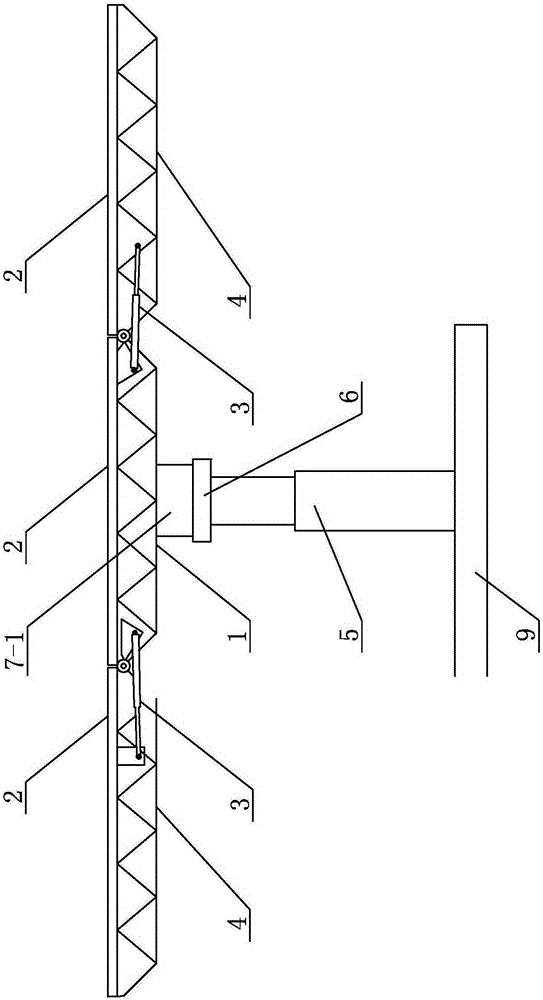

[0022] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 Describe this embodiment, which includes a general base 9, a lifting mechanism 5, a slewing mechanism 6, a tilting mechanism 7, an upper truss 1, a plurality of side trusses 4, a plurality of actuators 3 and a plurality of solar panels 2, The general base 9 is arranged horizontally, the lifting mechanism 5, the slewing mechanism 6, the tilting mechanism 7, and the upper truss 1 are sequentially arranged on the general base 9 from bottom to top, and the plurality of side trusses 4 are evenly arranged on the upper truss 1 around, each side truss 4 is hinged with the upper truss 1, a solar cell panel 2 is arranged on the top surface of each side truss 4 and the top surface of the upper truss 1, and the solar cell panel 2 on each side truss 4 It is connected with the solar panel 2 on the top surface of the upper truss 1 through an ac...

specific Embodiment approach 2

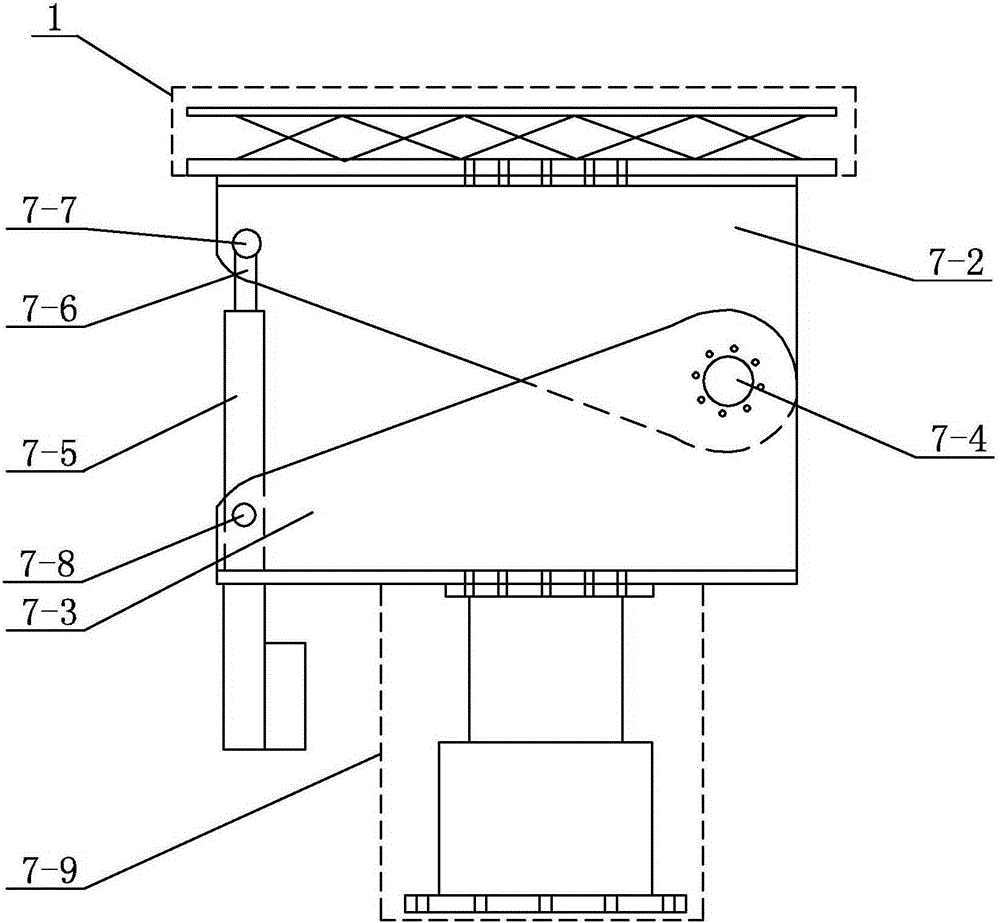

[0024] Specific implementation mode two: combination figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, the tilting mechanism 7 of this embodiment includes a housing 7-1, a moving seat body 7-2, a static seat body 7-3, a tilting shaft 7-4, an electric push rod cover 7-5 and an electric push and pull rod 7-6 , the moving shaft 7-7 and the static shaft 7-8, the moving seat body 7-2, the static seat body 7-3 and the tilting shaft 7-4 are all located in the shell 7-1, the moving seat body 7-2 and the The bottom surface of the upper truss 1 is fixedly connected, the static seat body 7-3 is fixedly connected to the slewing mechanism 6, the static seat body 7-3 is hinged with the dynamic seat body 7-2 through the tilting shaft 7-4, and the electric pusher The rod sleeve 7-5 is hinged with the static seat body 7-3 through the static shaft 7-8, and one end of the electric push-pull rod 7-6 is inserted in the electric push rod sleeve 7-5, and the electric push-pu...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 1 , figure 2 , Figure 5 and Figure 6 Describe this embodiment, the lifting mechanism 5 described in this embodiment includes a lower flange 5-1, an upper flange 5-2, a lower oil cylinder seat 5-3, an upper oil cylinder seat 5-4, an oil cylinder 5-5, a fixed slide Block 5-6, movable slider 5-7, outer support body 5-8 and inner support body 5-9, the inner wall of described outer support body 5-8 is provided with fixed slider 5-6, inner support body 5 -9 is provided with a movable slider 5-7 on the outer wall, the inner support body 5-9 is sleeved in the outer support body 5-8 and is slidably connected with the outer support body 5-8, the outer support body 5-8 The bottom is fixedly connected to the lower flange 5-1, the top of the inner support body 5-9 is fixedly connected to the upper flange 5-2, the oil cylinder 5-5 is located in the inner support body 5-9, and the oil cylinder The cylinder barrel in 5-5 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com