Filling unit and method for filling a confectionery product into a mould or a container

一种糖果类、装填的技术,应用在糖食、包装、糖食工业等方向,能够解决配料活塞技术复杂、配料活塞清洁复杂等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

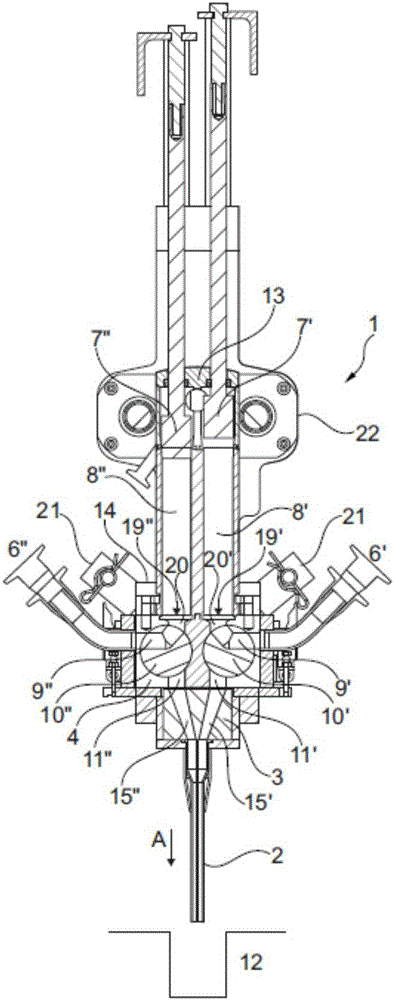

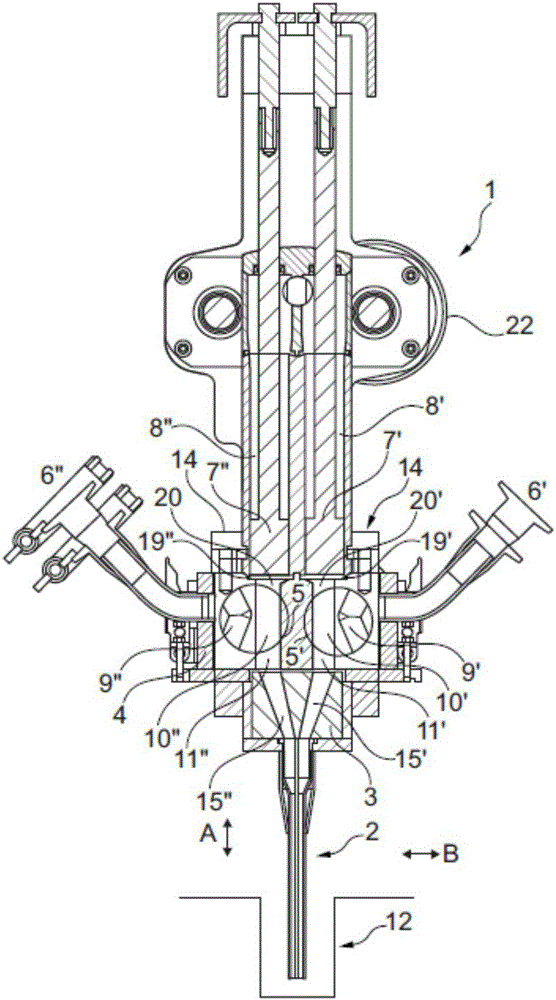

[0028] figure 1 and 2 The packing unit of the present invention is shown, said packing unit at figure 1 and figure 2 In two different positions, described in more detail below. The filling unit 1 is used in particular for dispensing ice cream and similar confectionary products as mentioned above. The filling unit comprises a filling box 4 . On the stuffing box 4 is mounted a cylindrical bushing 13 which is connected to the stuffing box 4 in a conventional manner, for example by a suitable number of bolts 14 .

[0029] The cylindrical casing 13 comprises two or more cylinders 8', 8", for example 3, 4, 5 or 6 cylinders. Each cylinder 8', 8" is equipped with a The batching piston in the 7', 7". Figure 1-2 An embodiment with two cylinders 8', 8" and two pistons 7', 7" is shown. Thus, the dosing units comprising cylinders 8', 8" and corresponding pistons 7', 7" may have the same or different diameters. In the stuffing box 4 each cylinder 8', 8" is provided with a valve 5'...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com