Chocolate fermented light cream and preparation method thereof

A technology of cream and chocolate, applied in cocoa, food science, application, etc., to achieve the effect of fine and smooth taste and uniform texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

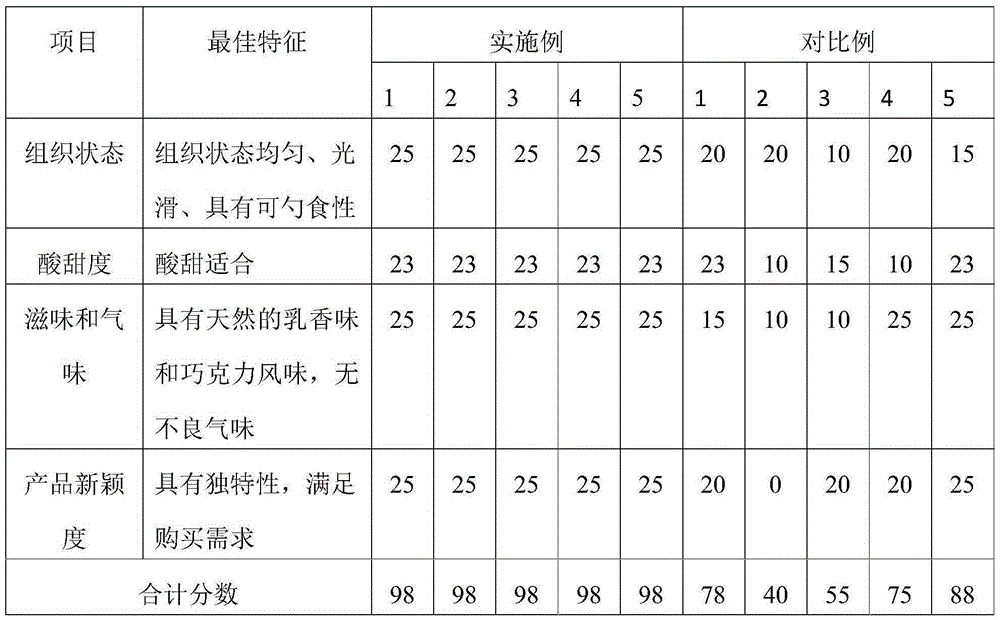

Examples

Embodiment 1

[0034] 1. Standardized cream to 20% fat.

[0035] 2. The raw materials are mixed, homogenized, sterilized and then cooled; the raw materials include 87% cream, 8% white granulated sugar and 5% dark chocolate pulp. Firstly, the cream and the sweetener are mixed and homogenized, the homogenization pressure is 15Mpa, and the homogenization temperature is 65°C. Immediately mix it with the melted chocolate mass, and sterilize it at 70°C for 10 minutes, and cool it to 30°C after sterilization.

[0036] 3. Fill and inoculate the starter, FD-DVSXPL-1 The dosage of bacteria is 200U / 1000L. Fermentation was carried out at 30° C. until the pH value reached 4.3 to obtain chocolate fermented cream.

[0037] 4. Refrigerate at 4-10°C.

Embodiment 2

[0039] 1. Standardized cream to 40% fat.

[0040] 2. The raw materials are mixed, homogenized, sterilized and then cooled; the raw materials include 88% cream and 12% milk chocolate. First, the cream and the sweetener are mixed and homogenized, the homogenization pressure is 5Mpa, and the homogenization temperature is 45°C. Immediately mix with the melted chocolate mass, and sterilize at 75°C for 10 minutes, then cool to 37°C after sterilization.

[0041] 3. Fill and inoculate the starter, FD-DVSXPL-1 The dosage of bacteria is 200U / 1000L. Fermentation was carried out at 37°C until the pH value reached 4.4 to obtain chocolate fermented cream.

[0042] 4. Refrigerate at 4-10°C.

Embodiment 3

[0044] 1. Standardized cream to 25% fat.

[0045]2. The raw materials are mixed, homogenized, sterilized and then cooled; the raw materials include 87% of cream, 5% of white sugar and 8% of dark chocolate pulp. First mix and homogenize the cream and sweetener, the homogenization pressure is 10Mpa, and the homogenization temperature is 60°C. Immediately mix it with the melted chocolate slurry, and then sterilize it at 85°C for 5 minutes, and cool it to 32°C after sterilization.

[0046] 3. Fill and inoculate the starter, FD-DVSCHN-19, the dosage of the strain is 100U / 1000L; ferment at 32°C until the pH value reaches 4.5 to obtain chocolate fermented cream.

[0047] 4. Refrigerate at 4-10°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com