Micro-fluidic chip used for capturing and rotating micro-size particles and preparation method and application of micro-fluidic chip

A microfluidic chip, micro-scale technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve problems such as high requirements for electrical properties, inability to achieve effective rotation, etc., to achieve good universality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

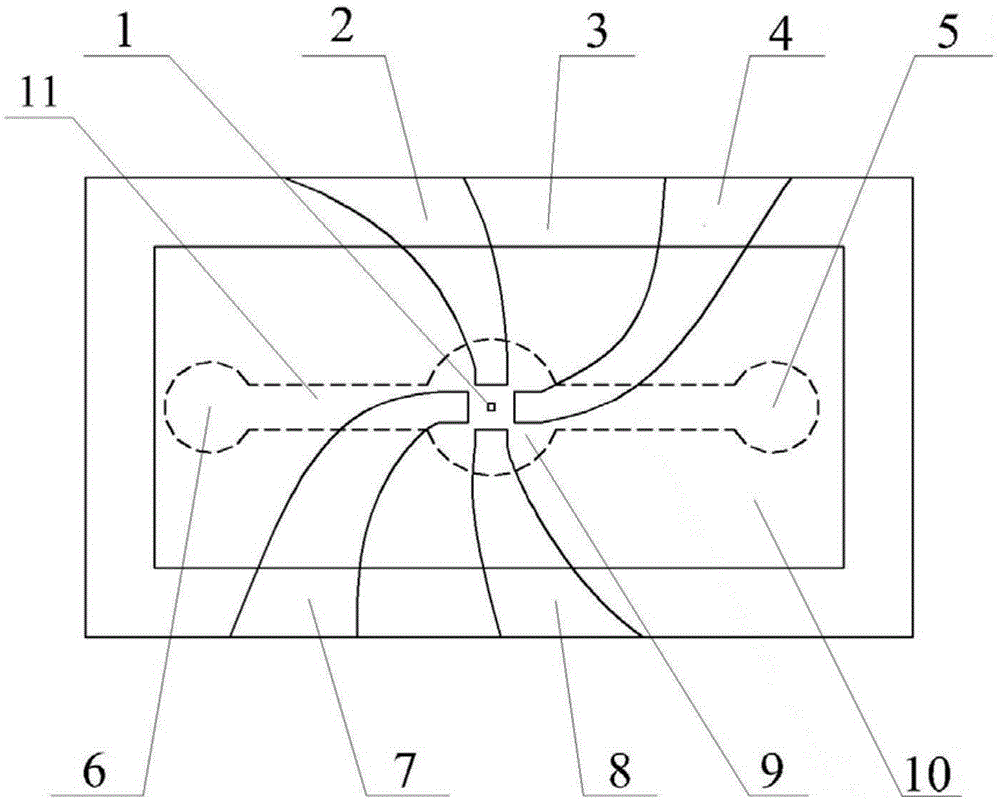

[0051] Specific implementation plan one: combine figure 1 Describe this embodiment in detail. This embodiment is a microfluidic chip for capturing and rotating microscale particles. The microfluidic chip for capturing and rotating microscale particles consists of a PDMS cover sheet 10 and an ITO glass substrate 3 ;

[0052] The central position of the ITO glass substrate 3 is provided with a square suspension electrode 1, an excitation electrode a2 is arranged behind the square suspension electrode 1, an excitation electrode b7 is arranged on the left side of the square suspension electrode 1, and an excitation electrode b7 is arranged in front of the square suspension electrode 1. Excitation electrode c8, the excitation electrode d4 is set on the right side of the square suspension electrode 1;

[0053] The said square suspension electrode 1, the excitation electrode a2, the excitation electrode b7, the excitation electrode c8 and the excitation electrode d4 are obtained by ...

specific Embodiment approach 2

[0060] Embodiment 2: The differences between this embodiment and Embodiment 1 are: the side length of the square suspension electrode 1 is 300 μm; the distance between the excitation electrode a2 and the excitation electrode c8 is 2 mm; The distance between the excitation electrode b7 and the excitation electrode d4 is 2mm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0061] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the diameter of the circular inlet through hole 6 is 4 mm to 5 mm; the diameter of the circular outlet through hole 5 is 4mm-5mm; the diameter of the circular reaction chamber 9 is 5mm-10mm. Others are the same as in the first or second embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap