Solar photovoltaic substrate gantry type centrifugal rotary brush cleaning device

A technology for photovoltaic substrates and cleaning devices, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as accumulated gravel, scratches on photovoltaic panels, accumulation of gravel veneers, etc., to achieve protection and Long service life, high cleaning efficiency, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

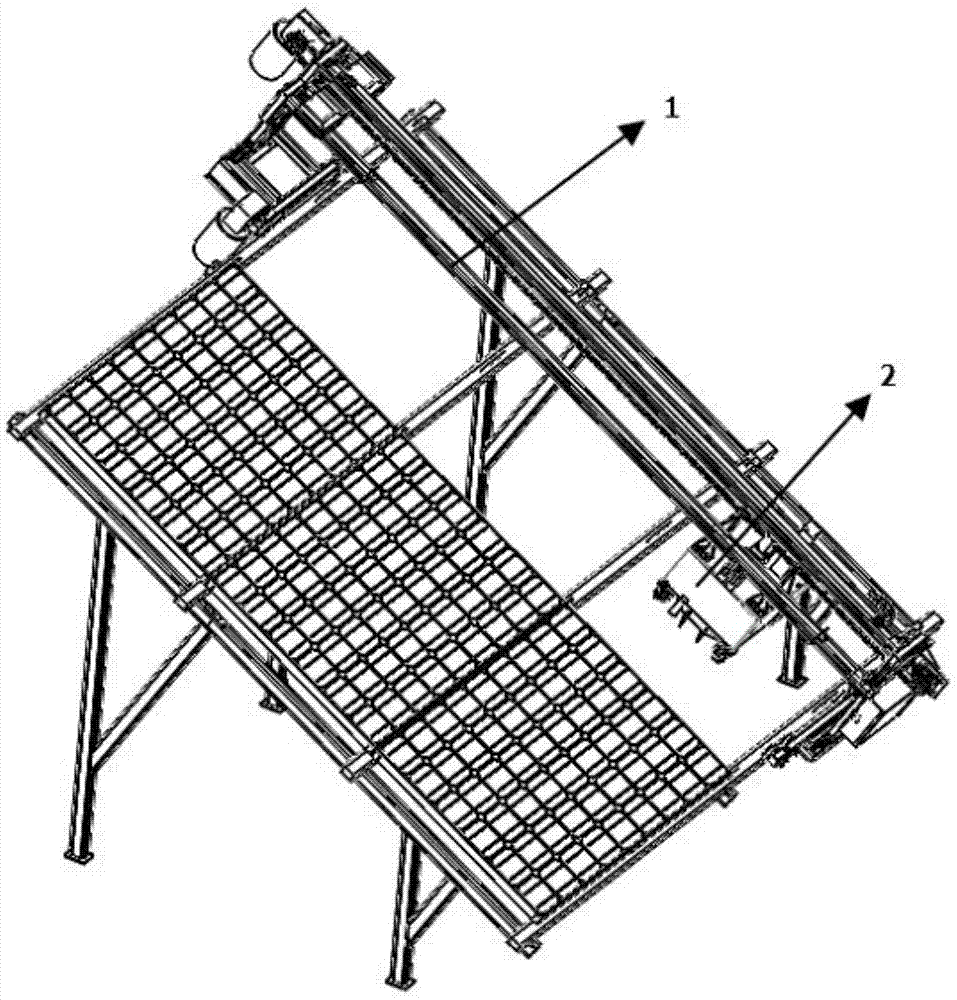

[0035] Such as figure 1 As shown, the solar photovoltaic substrate gantry type centrifugal cleaning device includes a gantry mechanical walking mechanism 1 and a centrifugal rotary cleaning mechanism 2. The centrifugal rotary cleaning mechanism 2 is hoisted on the gantry mechanical walking mechanism 1, and can The rail-type connecting profile 4 of the gantry-type mechanical traveling mechanism 1 moves left and right; The rotary brush cleaning mechanism 2 moves back and forth under the drive of the traversing active mechanism 3 and the traversing driven mechanism 5; the centrifugal rotary brush cleaning mechanism 2 cleans the objects to be cleaned while moving back and forth, left and right.

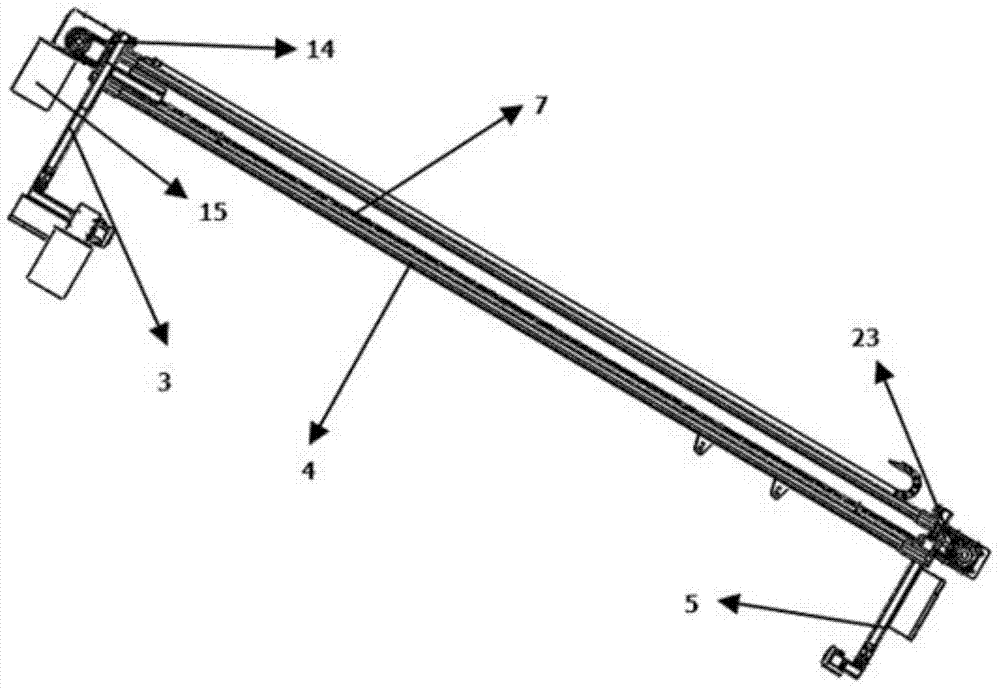

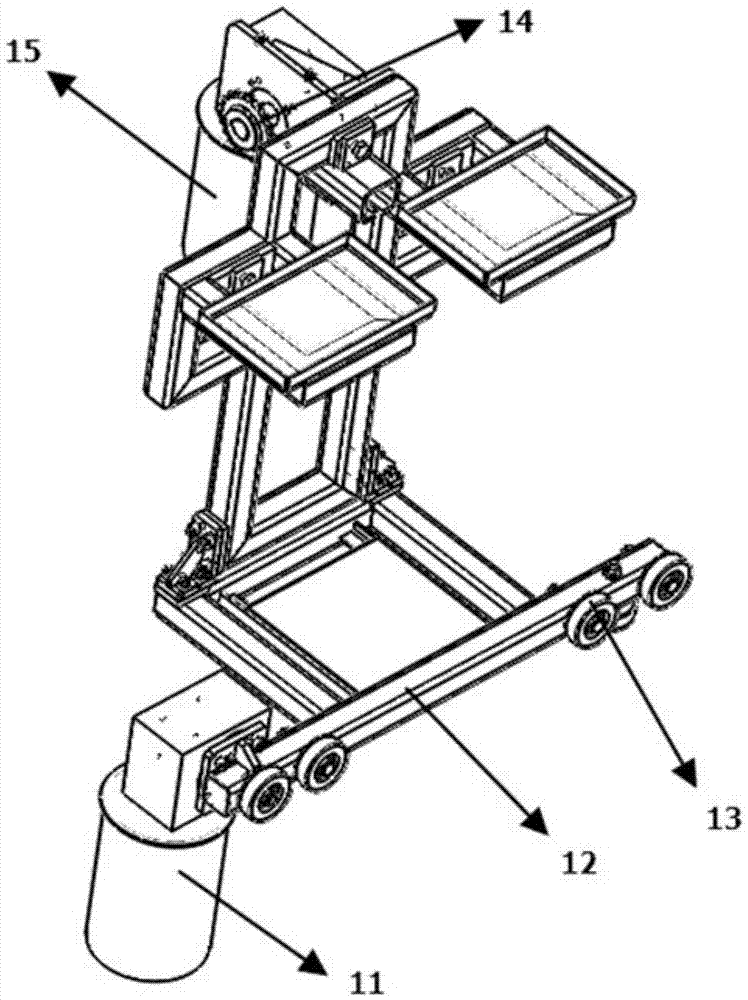

[0036] Such as figure 2 As shown, the gantry-type mechanical traveling mechanism 1 of the present invention mainly includes a rail-type connection profile 4 , a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com