Automatic checking and packaging equipment for transformer

A technology of automatic inspection and packaging equipment, applied in the field of transformer production, can solve problems such as labor-intensive, low efficiency, and prone to missing inspections, and achieve the effects of improving efficiency, reducing consumption, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

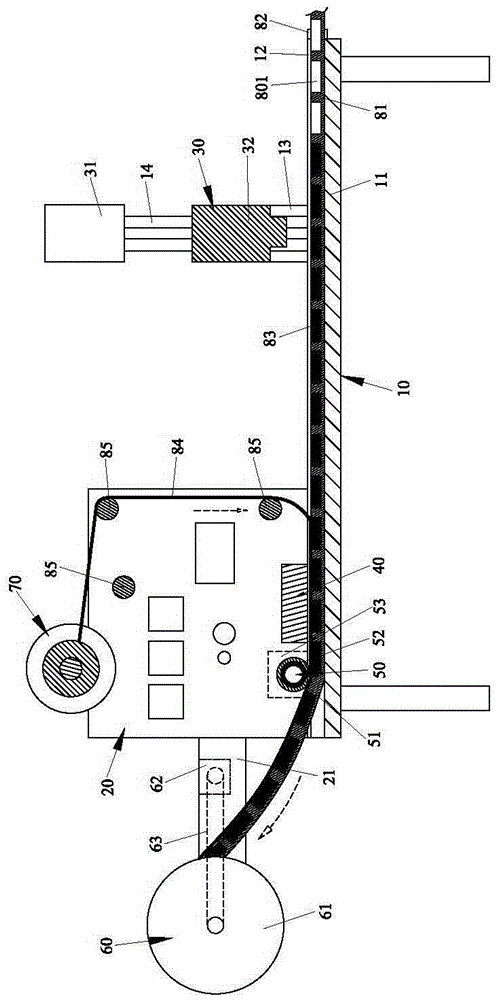

[0029] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, including frame 10, electrical control box 20, image recognition device 30, heating device 40, rolling device 50, winding device 60 and packaging film Unloading device 70.

[0030] The platform 11 of the frame 10 is concavely provided with a conveying trough 12 for guiding the belt-shaped packaging shell 81, and a photoelectric switch 82 is arranged on the side of the entrance of the conveying trough 12, and the photoelectric switch 82 is connected with the electrical control box 20 for communication. The switch 82 is used to detect whether the transformer 83 has been placed in the concave position 801 of the strip packaging shell 81 .

[0031] The electric control box 20, the image recognition device 30, the heating device 40 and the rolling device 50 are all arranged on the frame 10, and the image recognition device 30, the heating device 40 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com