Automatic assembling terminal machine

A technology of automatic assembly and terminal machine, which is applied in the assembly/disassembly of contacts, etc., which can solve the problems of low production efficiency, inability to handle complex terminals, and low product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

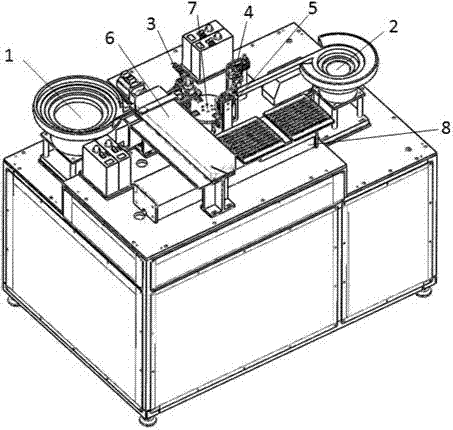

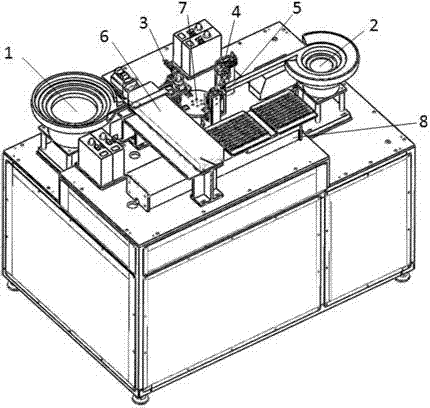

[0023] In general, figure 1 Shows the structure of the automatic terminal assembly machine according to the first embodiment of the present invention, as figure 1 As shown, the automatic terminal assembly machine of the present invention includes a pick-and-place unit, a magnetic nest alignment unit 1 , a terminal alignment unit 2 , a magnetic nest placement unit 3 , a terminal placement unit 4 , and a terminal assembly unit 5 .

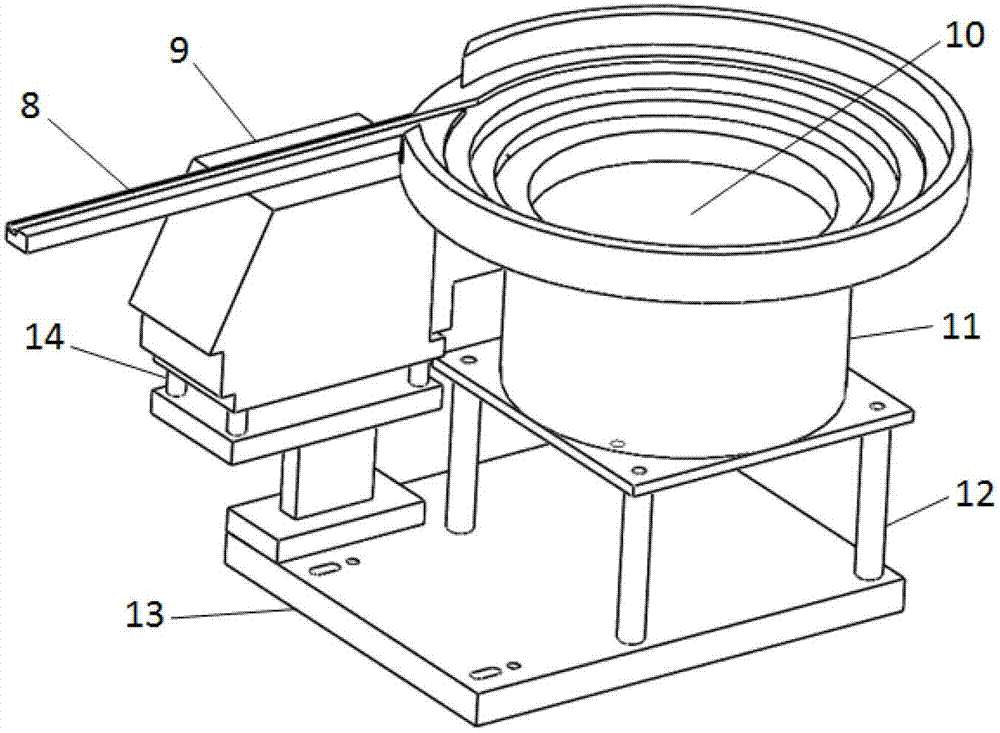

[0024] Specifically, figure 2 It shows the structure of the magnetic socket alignment unit of the automatic assembly terminal machine according to the present invention, such as figure 2 As shown, the magnetic nest alignment unit structure of the present invention includes a magnetic nest direct vibration guide rail 8, a magnetic nest direct vibration 9, a magnetic nest vibration plate 10, a magnetic nest circular vibration 11, a circular vibration support 12, a fixed plate 13, and a direct vibration support. 14.

[0025] The magnetic nest circu...

Embodiment 2

[0041] The structure of the automatic assembly terminal machine of the second embodiment of the present invention is as follows Figure 8 shown. The automatic assembly terminal machine of the second embodiment has basically the same components and functions as the automatic assembly terminal machine of the first embodiment, and the same units also use the same reference numerals. The only difference is that after the assembly is completed, The products are neatly arranged on the assembly rod fixture through the cooperation of the picking unit and the delivery unit, so as to speed up the output of the products. The automatic terminal assembly machine in the second embodiment of the present invention may also preferably include a picking unit 7 and a delivery unit 8 . Those skilled in the art should understand that the above two units can also be used in the automatic terminal assembly machine of the first embodiment.

[0042] Specifically, Figure 9 Shows the picking unit st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com