Automatic-locking lifter lifting platform

A lifting platform, automatic locking technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of easy damage, long time, high maintenance and repair costs, etc., to improve safety performance, prolong service life, and protect products that are not easily worn Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

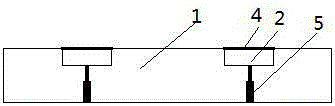

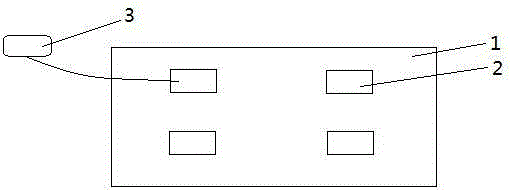

[0022] see figure 1 , figure 2 , figure 1 , figure 2 It is an automatic locking lifting platform of the present invention. According to the automatic locking lifting platform of the present invention, the four corners of the lifting platform 1 are respectively provided with a rectangular lifting block 2, and an automatic telescopic rod 5 is connected under the lifting block.

[0023] In addition, the width of the lifting block 2 is 250mm, and the length is 800mm.

[0024] Furthermore, the lifting block 2 is connected 3 through the control panel.

[0025] Moreover, there is a pressure sensing device 4 at the bottom of the lifting block 2 .

[0026] At the same time, the surface of the lifting platform 1 is provided with a cross-shaped raised pattern.

[0027] In addition, the surface 1 of the lifting platform is provided with a protective film.

[0028] Further, the components of the protective film are: 50% polyethylene, 40% polyacrylic resin, 2% surfactant, and 8% lu...

Embodiment 2

[0030] An automatic locking lift lifting platform, each of the four corners of the lifting platform 1 is provided with a rectangular lifting block 2, and an automatic telescopic rod 5 is connected to the bottom of the lifting block 2.

[0031] In addition, the width of the lifting block 2 is 400mm, and the length is 1000mm.

[0032] Furthermore, the lifting block 2 is connected 3 through the control panel.

[0033] Moreover, there is a pressure sensing device 4 at the bottom of the lifting block 2 .

[0034] At the same time, the surface of the lifting platform 1 is provided with a cross-shaped raised pattern.

[0035] In addition, the surface of the lifting platform 1 is provided with a protective film.

[0036] Further, the components of the protective film are: 70% polyethylene, 20% polyacrylic resin, 5% surfactant, and 5% lubricant.

Embodiment 3

[0038] An automatic locking lift lifting platform, each of the four corners of the lifting platform 1 is provided with a rectangular lifting block 2, and an automatic telescopic rod 5 is connected to the bottom of the lifting block 2.

[0039] In addition, the width of the lifting block 2 is 350mm, and the length is 900mm.

[0040] Furthermore, the lifting block 2 is connected 3 through the control panel.

[0041] Moreover, there is a pressure sensing device 4 at the bottom of the lifting block 2 .

[0042] At the same time, the surface of the lifting platform 1 is provided with a cross-shaped raised pattern.

[0043] In addition, the surface of the lifting platform 1 is provided with a protective film.

[0044] Further, the components of the protective film are: 60% polyethylene, 35% polyacrylic resin, 1.8% surfactant, and 3.2% lubricant.

[0045] After the vehicle travels from the approach bridge to the lifting platform 1, once the pressure sensing device 4 on each liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com