Method for installing anti-pull part

An installation method and technology of the body, which are applied in the directions of building components, earthquake resistance, building types, etc., can solve the problems of poor structural stability of light steel buildings, poor seismic capacity of light steel buildings, and poor deformation resistance of pull-out parts, and are not easy to overturn. , good stability, improve the effect of anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

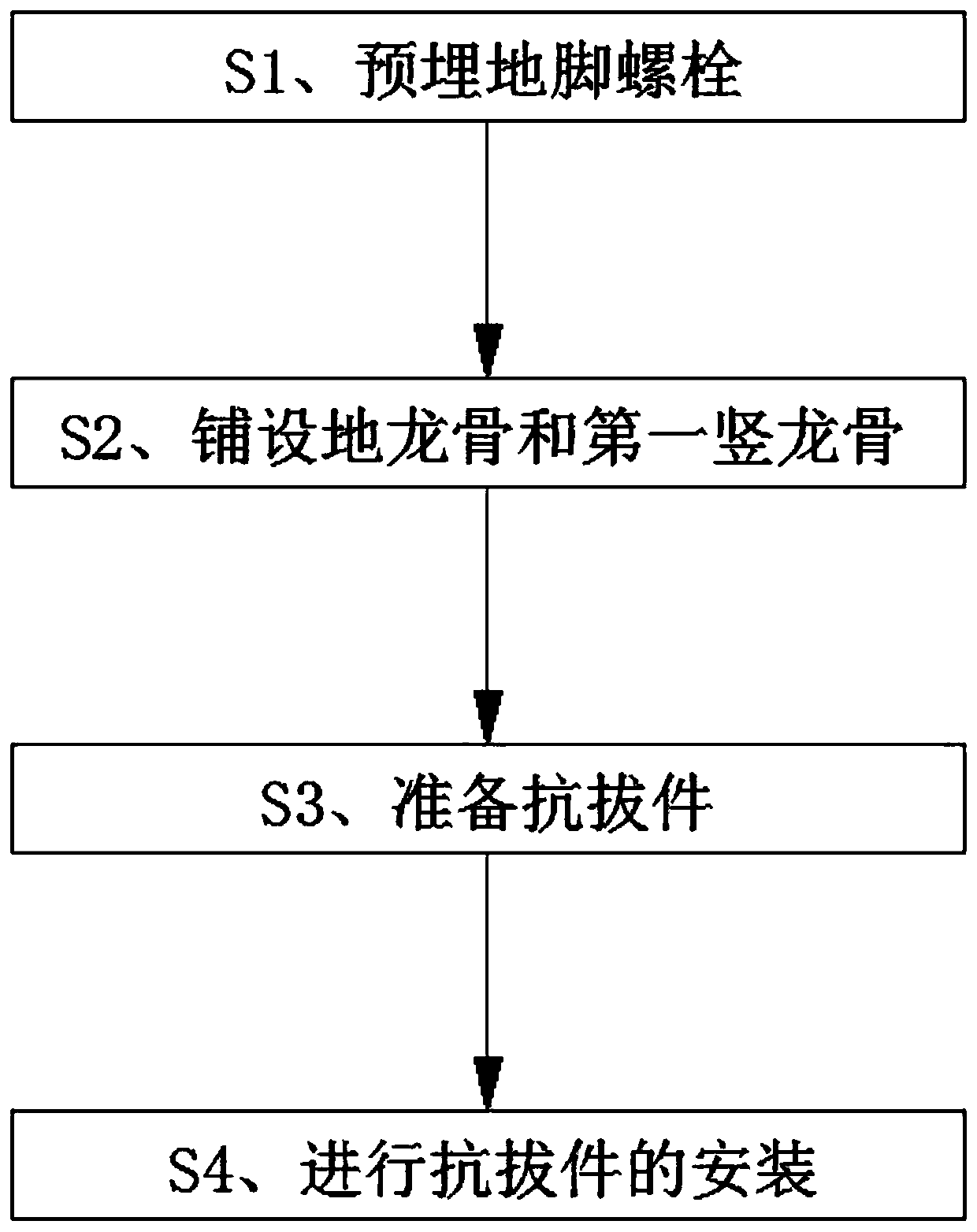

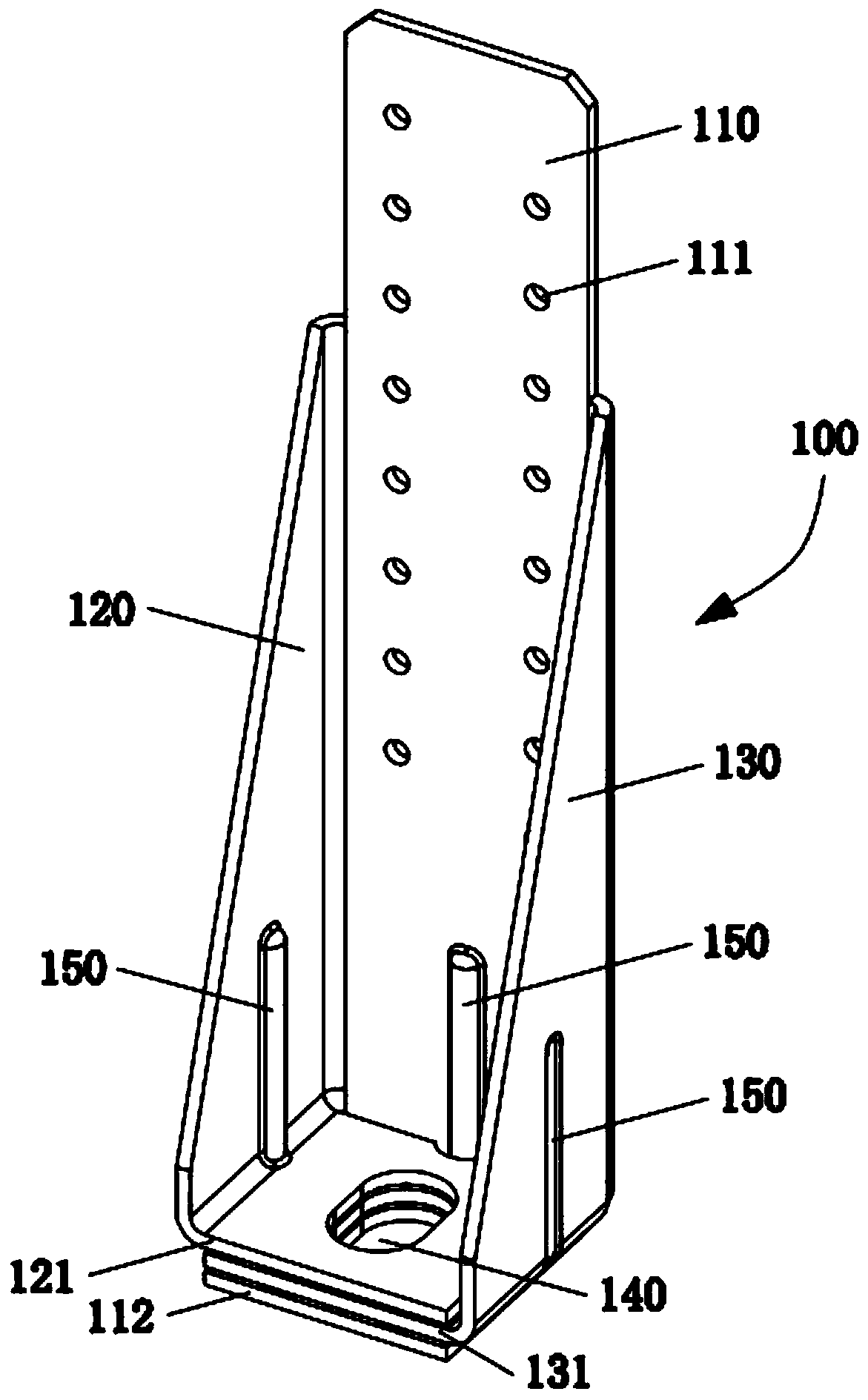

[0064] Cooperate figure 1 , Figure 3 to Figure 7 As shown, the invention discloses a method for installing an anti-pull part, comprising the following steps:

[0065] S1. Pre-bury the anchor bolts 400, pour concrete to form the foundation 200, and expose the anchor bolts 400 to the foundation 200.

[0066] S2. Lay the ground keel 310 , and the ground keel 310 is fixed on the foundation 200 through the expansion bolt 500 .

[0067] S3. Lay the first vertical keel 320 in the direction perpendicular to the ground keel 310, so that the first vertical keel 320 is located near the anchor bolt 400, and then prepare the anti-pull piece 100, and both the ground keel 310 and the first vertical keel 320 are used The C-shaped keel or the U-shaped keel fixes the first connecting body 110 of the anti-pull member 100 to the back of the first vertical keel 320, so that the second connecting body 120 and the third connecting body 130 respectively lean against the first vertical keel 320 si...

Embodiment 2

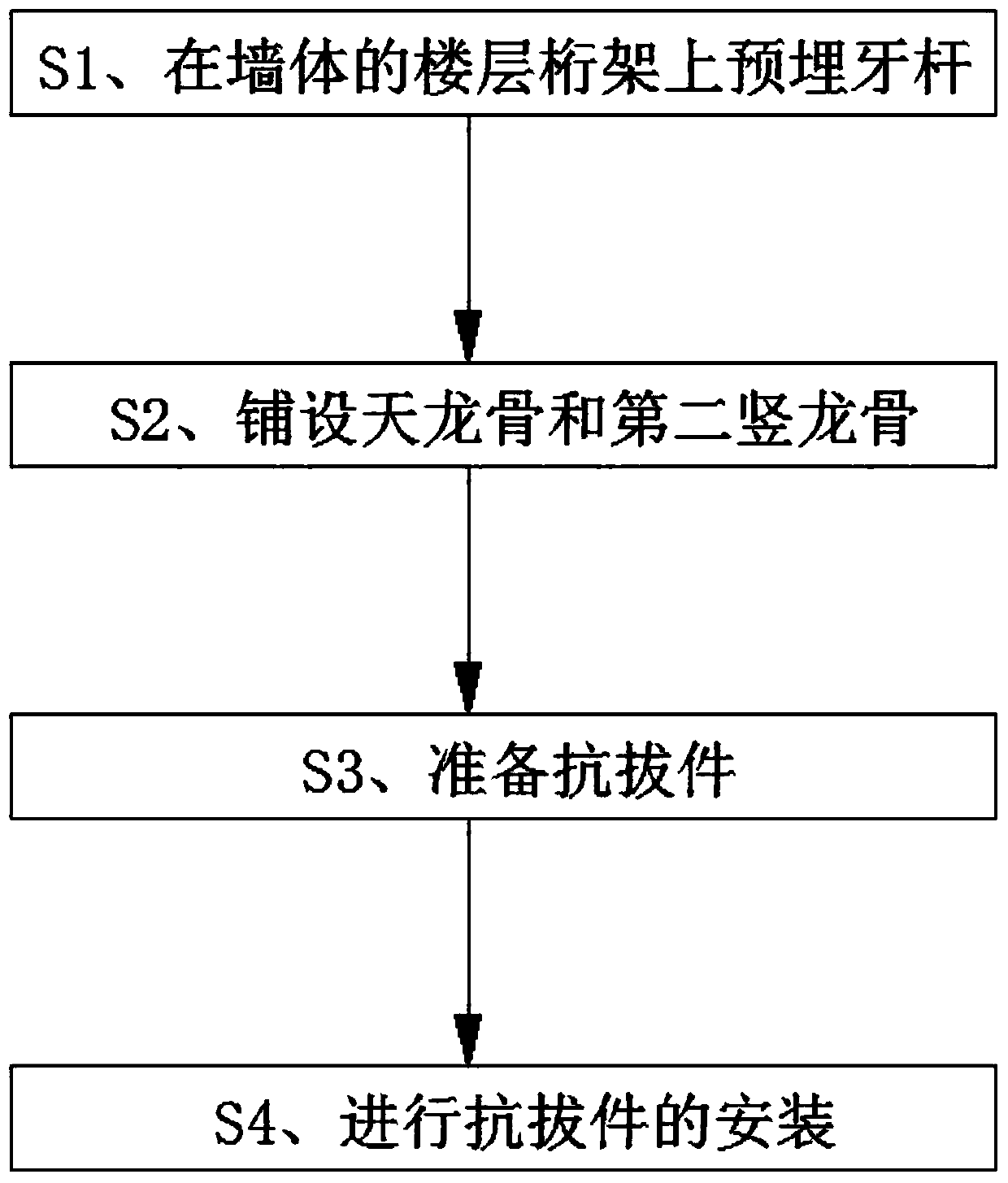

[0082] Cooperate Figure 2 to Figure 6 , Figure 8 and Figure 9 As shown, the invention discloses a method for installing an anti-pull part, comprising the following steps:

[0083] S1. Pre-embed the tooth bar 800 on the floor truss 710 of the wall, and expose the tooth bar 800 to the floor truss 710 . The tooth bar 800 is located in the middle of the floor truss 710 .

[0084] S2. Lay the sky keel 720 at the upper and lower ends of the floor truss 710 of the wall, and lay the second vertical keel 730 in the direction perpendicular to the sky keel 720, and make the second vertical keel 730 close to the tooth bar 800, and the sky keel 720 and the second vertical keel 730 are all C-shaped keels or U-shaped keels, so that the first connecting body 110 of the pull-out member 100 is fixed to the back of the second vertical keel 730, so that the second connecting body 120 and the third connecting body 130 are against the two sides of the second vertical keel 730 respectively.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com