A new type of environmentally friendly selenium-enriched bio-organic fertilizer for bananas

A bio-organic fertilizer, a new type of technology, applied in the direction of application, fertilization device, fertilizer mixture, etc., to reduce production costs, promote soil loosening, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

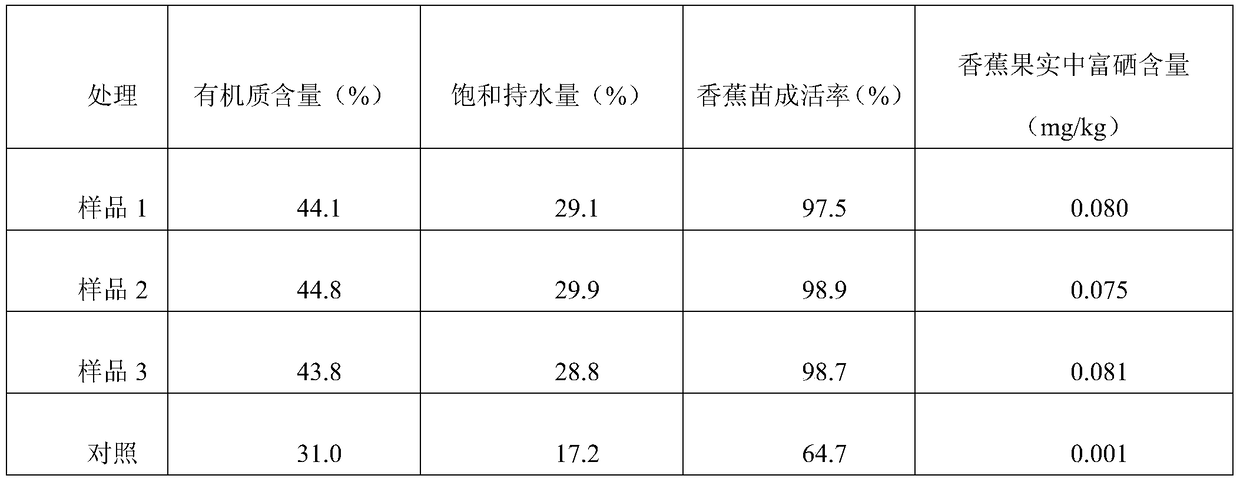

Examples

Embodiment 1

[0030] Take the following raw materials by weight: 55kg of alcohol waste liquid, 10kg of cassava residue, 20kg of coarse bran or oil bran, 10kg of selenium ore powder, 2.5-5.0kg of zinc sulfate, 0.05kg of selenium-enriched sweetener and 0.05kg of enzyme bacteria; The selenium content of selenium ore powder is ≥150mg / Kg, and the fineness is ≥60 mesh.

[0031] Its preparation method comprises the following steps:

[0032] (1) Mix the alcohol waste liquid, cassava residue and rice bran evenly, then add EM fermentation bacteria, and pile them up at a temperature of 40°C to ferment for 30 days, stirring once every 2 days to obtain a mixed fermentation product; the EM fermentation The dosage of bacteria is 0.1% of the total weight of alcohol waste liquid, cassava residue and rice bran;

[0033] (2) Mix selenium-enriched sweetener and enzyme bacteria with the mixed fermented product prepared in step (1), add tap water, and then pile it up at a temperature of 30°C for 60 days of ferm...

Embodiment 2

[0037] Take the following raw materials by weight: 65kg of alcohol waste liquid, 20kg of cassava residue, 30kg of coarse bran or oil bran, 25kg of selenium ore powder, 5.0kg of magnesium sulfate, 0.05kg of selenium-enriched sweetener and 0.05kg of enzyme bacteria; The selenium content of mineral powder is ≥150mg / Kg, and the fineness is ≥60 mesh.

[0038] Its preparation method comprises the following steps:

[0039] (1) Mix alcohol waste liquid, cassava dregs and rice bran evenly, then add EM fermentation bacteria, and pile them up at a temperature of 55°C for 60 days of fermentation, stirring once every 3 days to obtain a mixed fermentation product; the EM fermentation The dosage of bacteria is 0.5% of the total weight of alcohol waste liquid, cassava residue and rice bran;

[0040] (2) Mix selenium-enriched sweetener and enzyme bacteria with the mixed fermented product prepared in step (1), add tap water, and then pile it up at a temperature of 35°C for 90 days of fermentat...

Embodiment 3

[0044] Take the following raw materials by weight: 60kg of alcohol waste liquid, 15kg of cassava residue, 25kg of coarse bran or oil bran, 20kg of selenium ore powder, 3.0kg of borax, 0.05kg of selenium-enriched sweetener and 0.05kg of enzyme bacteria; The selenium content of the powder is ≥150mg / Kg, and the fineness is ≥60 mesh.

[0045] Its preparation method comprises the following steps:

[0046] (1) Mix alcohol waste liquid, cassava dregs and rice bran evenly, then add EM fermentation bacteria, pile them up and ferment for 45 days at a temperature of 50°C, and stir once every 3 days to obtain a mixed fermentation product; the EM The amount of fermentation bacteria is 0.3% of the total weight of alcohol waste liquid, cassava residue and rice bran;

[0047] (2) Mix selenium-enriched sweetener and enzyme bacteria with the mixed fermented product prepared in step (1), add tap water, and then pile it up at a temperature of 33°C to ferment for 80 days, turning it every 3 days ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com