Low-pressure liquid separation system

A liquid separation and low pressure technology, which is applied in the field of low pressure liquid separation system of medium pipeline of heat utilization equipment, can solve the problems of low working efficiency of equipment, unsightly appearance, waste of medium energy, etc., and achieves high pipeline layout beauty and medium energy storage Uniform and pipe-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the accompanying drawings.

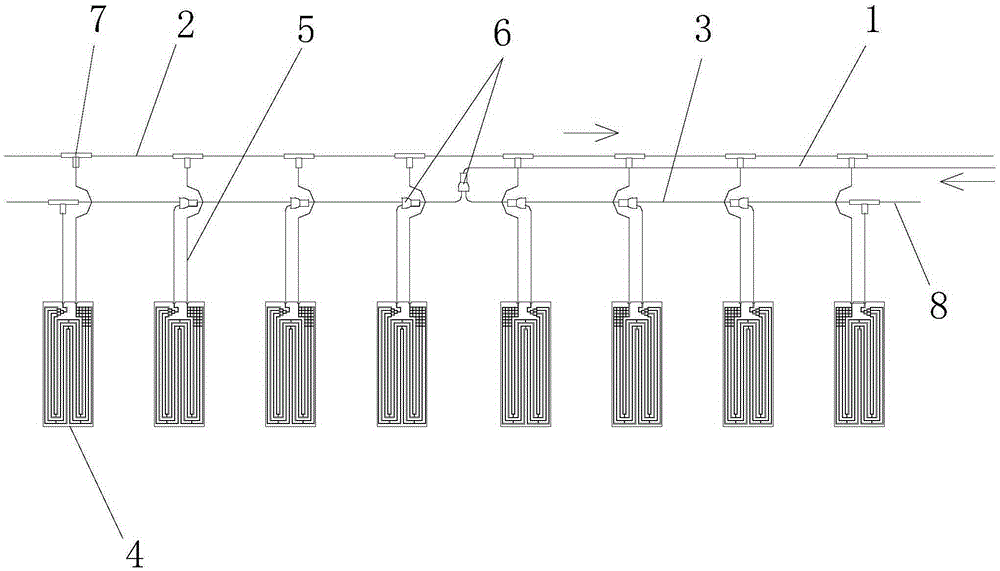

[0018] Such as figure 1 As shown, a low-pressure liquid distribution system provided in this embodiment includes a liquid inlet pipe 1 and an air outlet pipe 2. The liquid inlet pipe 1 is divided into two and communicated with two liquid distribution pipes 3 of equal length. The liquid pipes 3 are respectively connected to four heat collecting plates 4 through equidistant pipes 5, and the two liquid distribution pipes 3 are connected to eight heat collecting plates 4 in total. The joints of the liquid pipes are arranged symmetrically, and the heat collecting plates 4 are respectively connected to the air outlet pipes 2 through equidistant pipes 5 and the connection ports are arranged equidistantly on the air outlet pipes 2 .

[0019] The liquid inlet pipe 1 is divided into two by a Y-shaped tee 6 and connected to two liquid-distributing pipes 3, and the pipeline for com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com