Manufacturing method of color filter substrate and color filter substrate

A technology of color filter substrate and manufacturing method, which is applied in optics, nonlinear optics, instruments, etc., can solve the problems of increased manufacturing cost, large QD consumption, and difficulty in realization, and achieves the effect of low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

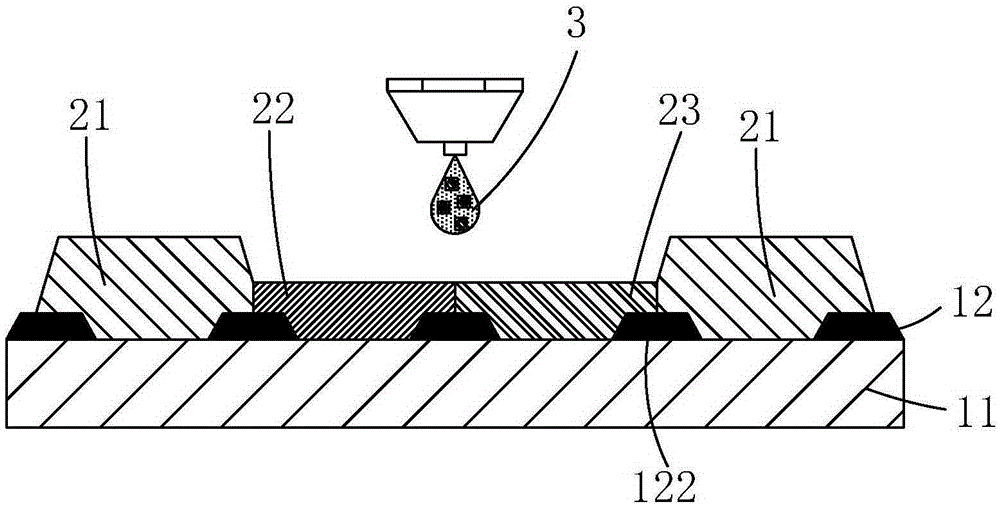

[0037] see Figure 1-Figure 4 , the present invention firstly provides a method for manufacturing a color filter substrate, which can be applied to the manufacture of common color filter substrates, including the following steps:

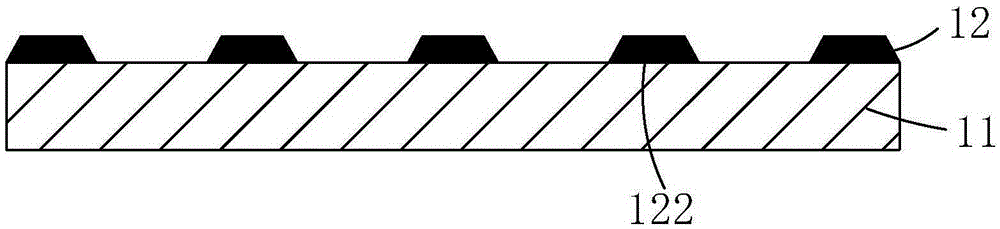

[0038] Step 1, such as figure 1 As shown, a substrate 11 is provided on which a black matrix 12 is formed.

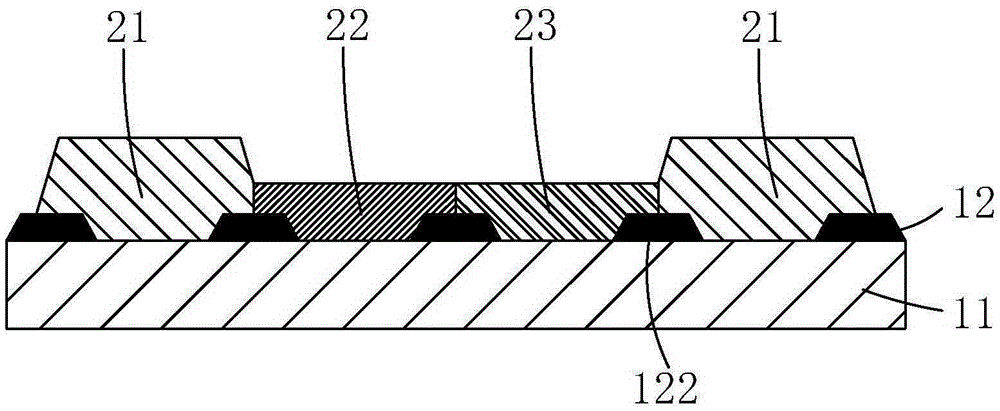

[0039] Step 2, such as figure 2As shown, several transparent color-resist blocks 21, several red color-resist blocks 22, and several green color-resist blocks 23 arranged in sequence are formed on the substrate 11 and the black matrix 12; wherein, every two adjacent A red color resistance block 22 and a green color resistance block 23 are arranged between the transparent color resistance blocks 21, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com