Dynamic ore matching optimization method for mined ore

An optimization method and ore technology, applied in the direction of instruments, data processing applications, forecasting, etc., can solve problems such as meeting requirements, ineffective connection of iron transportation, restricting the normal production of dressing plants, etc. The selection is basically stable and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

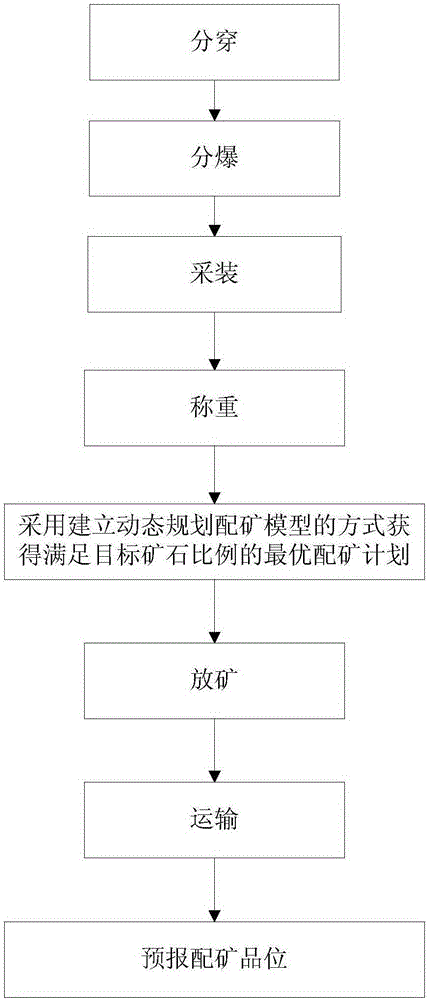

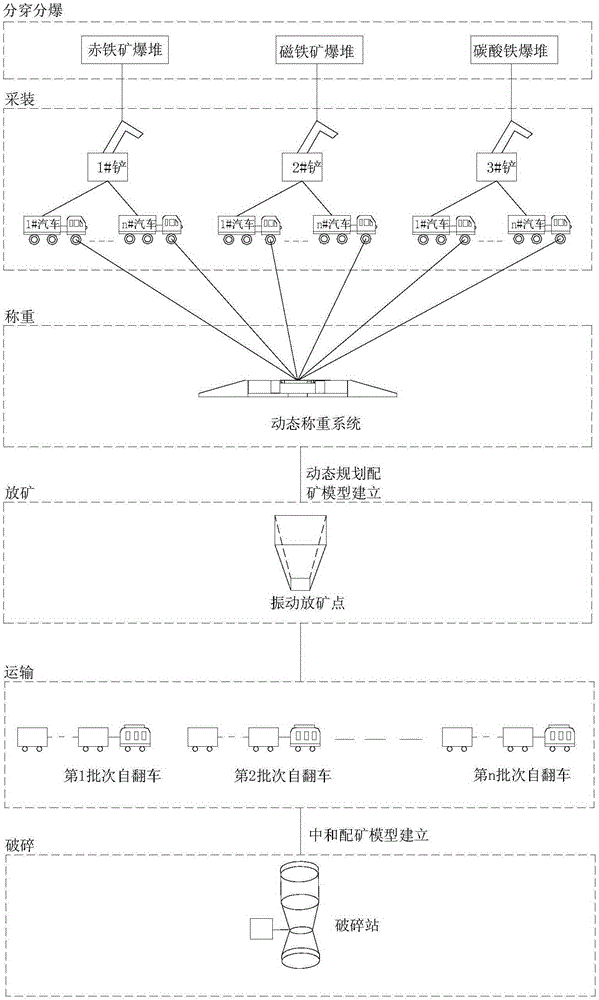

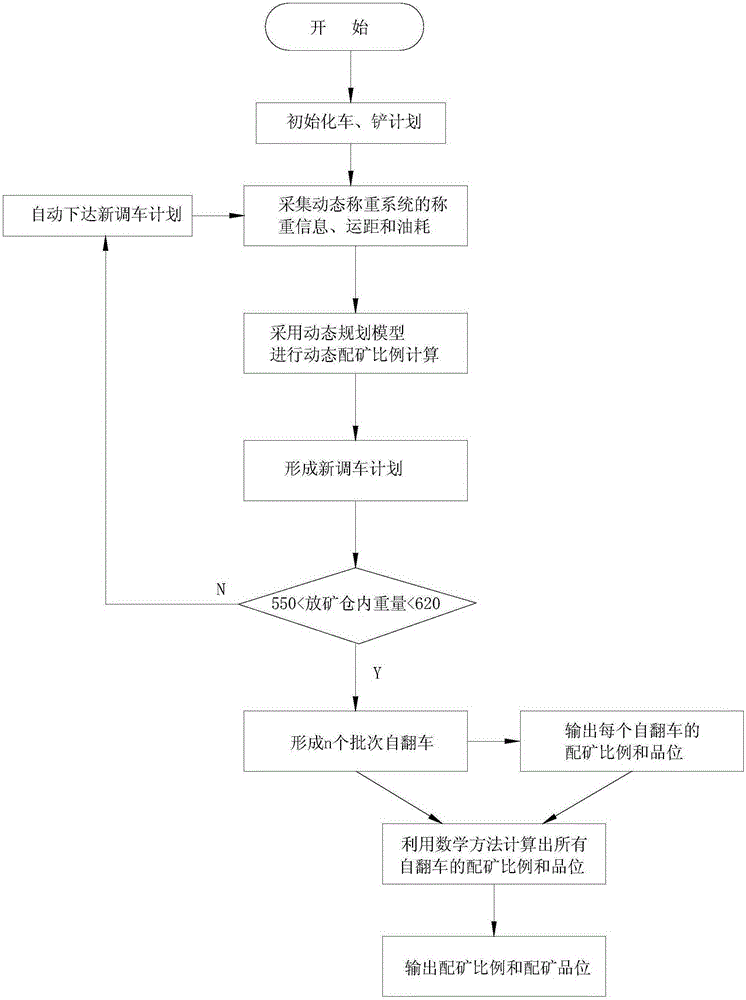

[0041] Such as figure 1 with figure 2 As shown, the mining intelligent ore dynamic ore blending optimization method in the embodiment of the present invention includes splitting, splitting, mining, weighing, and adopting the method of establishing a dynamic planning ore blending model to obtain the optimal ore blending plan that meets the target ore ratio, Ore drawing, transportation and ore blending grade forecast, the overall detailed flow chart of the method is as follows image 3As shown, the details are as follows:

[0042] Separate piercing and separate blasting: Through geological survey, different types of ores are perforated and blasted separately. According to the analysis of blast hole test data, different types of explosive piles are formed, hematite, magnetite and iron carbonate, among which iron carbonate belongs to For refractory ore...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com