Crop harvesting ploughing tool

A technology for crops and plow tools, which is applied in the field of crop harvesting plow tools, and can solve problems such as unsatisfactory cleanliness and leakage of green onions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

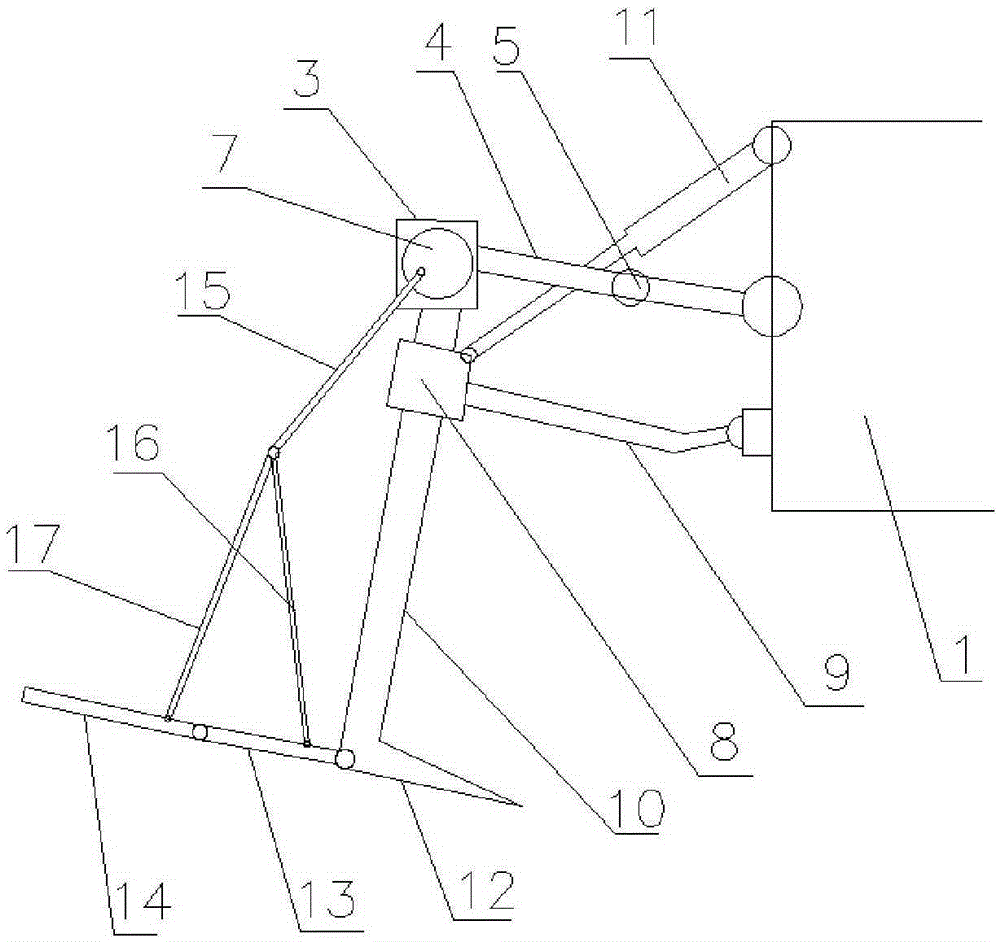

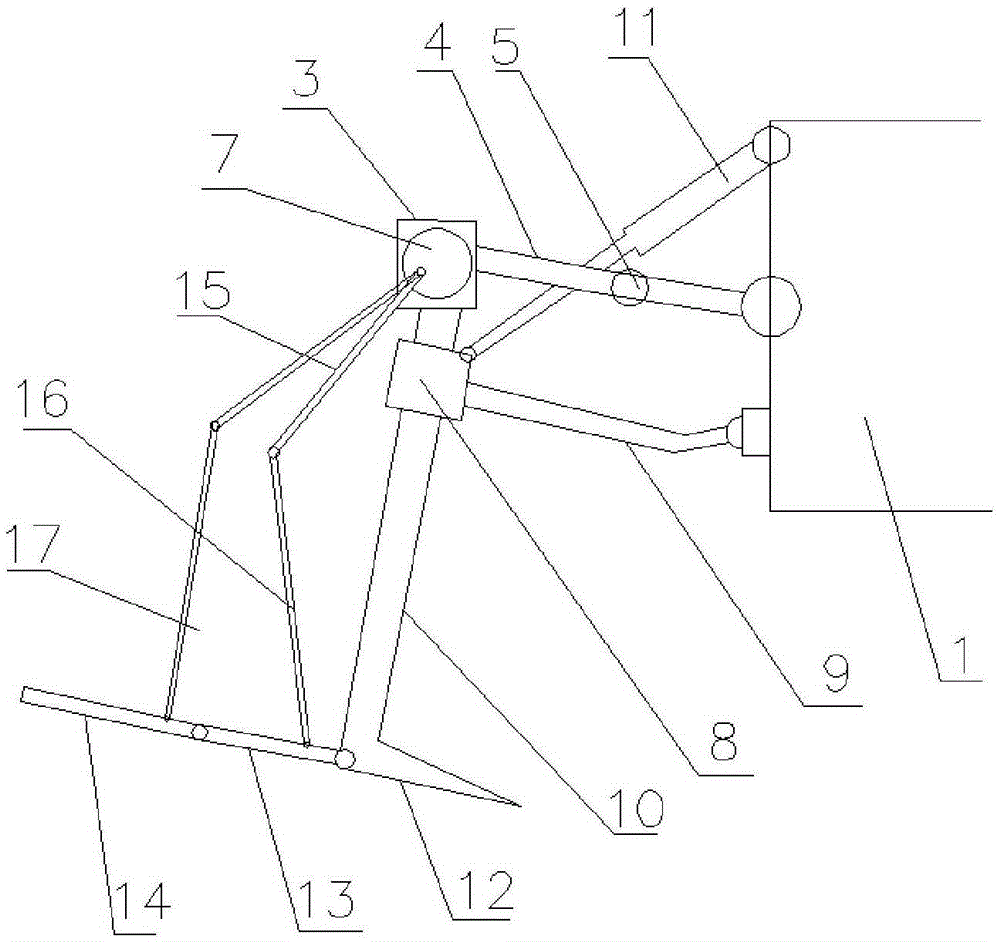

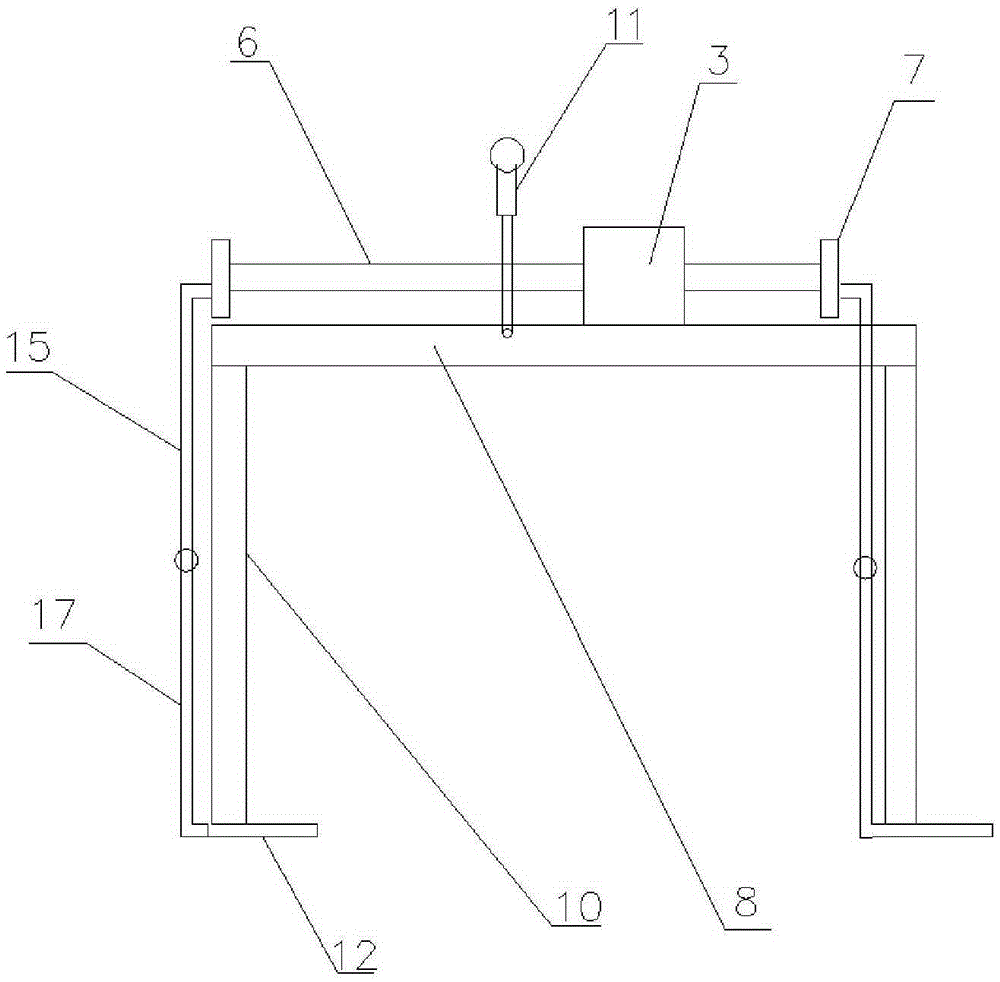

[0017] Such as Figure 1 to Figure 4 As shown, the crop harvesting plow of the present invention includes a support frame 2 connected to the tractor 1, the support frame 1 includes a beam 8, the two ends of the beam 8 are connected to the upper longitudinal beam 9 and the lower longitudinal beam 10, and the transfer case 3 is connected to the transmission The shaft 4 and the drive shaft 4 are connected to the power output shaft of the tractor 1 through the universal joint 5, the upper longitudinal beam 9 is hinged on the tractor 1, the crossbeam 8 is hinged with a hydraulic rod 11, and the other end of the hydraulic rod 11 is hinged on the tractor 1.

[0018] The transfer case 3 is connected to the eccentric wheel 7 through the connecting shaft 6, the vibrating rod 8 is connected to the eccentric wheel 7, and the soil lifting plow 12 is fixedly installed under the lower longitudinal beam 10. The fork is hinged to the rear vibration fork 14, and the front vibration fork 13 is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com