DIY module furniture and application thereof

A technology of furniture and connecting parts, applied in the field of furniture, can solve the problems of manual operation accounting for a large part, poor product quality management, and inability to assemble multiple times, and solve the problems of increasing production labor costs, simple and practical connection methods, The effect of meeting individual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

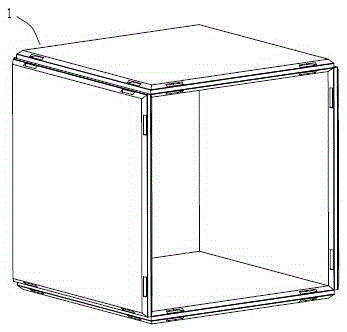

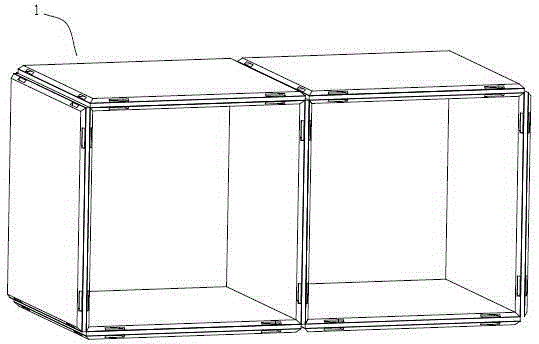

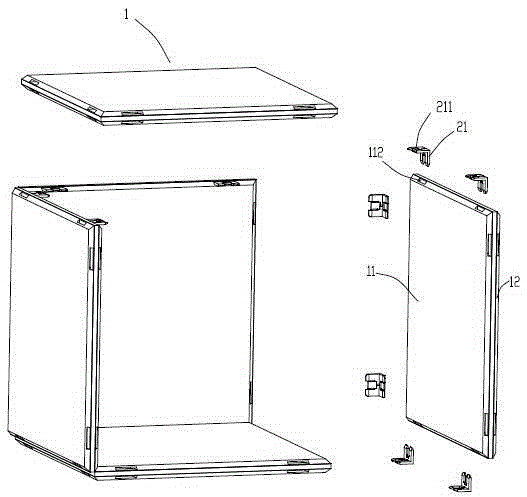

[0021] refer to Figure 1 to Figure 7 As shown, a DIY modular furniture includes a panel 1 and a connecting piece injection-molded by engineering plastics. The panel 1 includes left and right panels 11, 12 and a The middle connecting bar 13; the left and right panels 11, 12 are formed with some buckles 113, 123 on the side facing the middle connecting bar 13, and the middle connecting bar is correspondingly provided with a draw-in groove for accommodating the buckles; the edge of each panel is provided with The hypotenuses 111, 121 are provided with buckle grooves 112, 122; the connectors include L-shaped connectors 21, and the L-shaped connectors are elastically connected to the buckle slots through the vertical sides and the convex buckles 211 on the vertical sides. Buckle connection; adjacent boards are connected and installed through this type of connector 21. According to the needs of the combined furniture, the panels can be square or rectangular.

[0022] During produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com