Preinstallation device of mechanical arm tooling

A terminal and manipulator technology, applied in the manufacturing field, can solve the problems of long online adjustment time, large time occupied by the terminal, poor ergonomics, etc., to reduce engineering intensity and online adjustment process risks, improve pre- The effect of installation accuracy and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

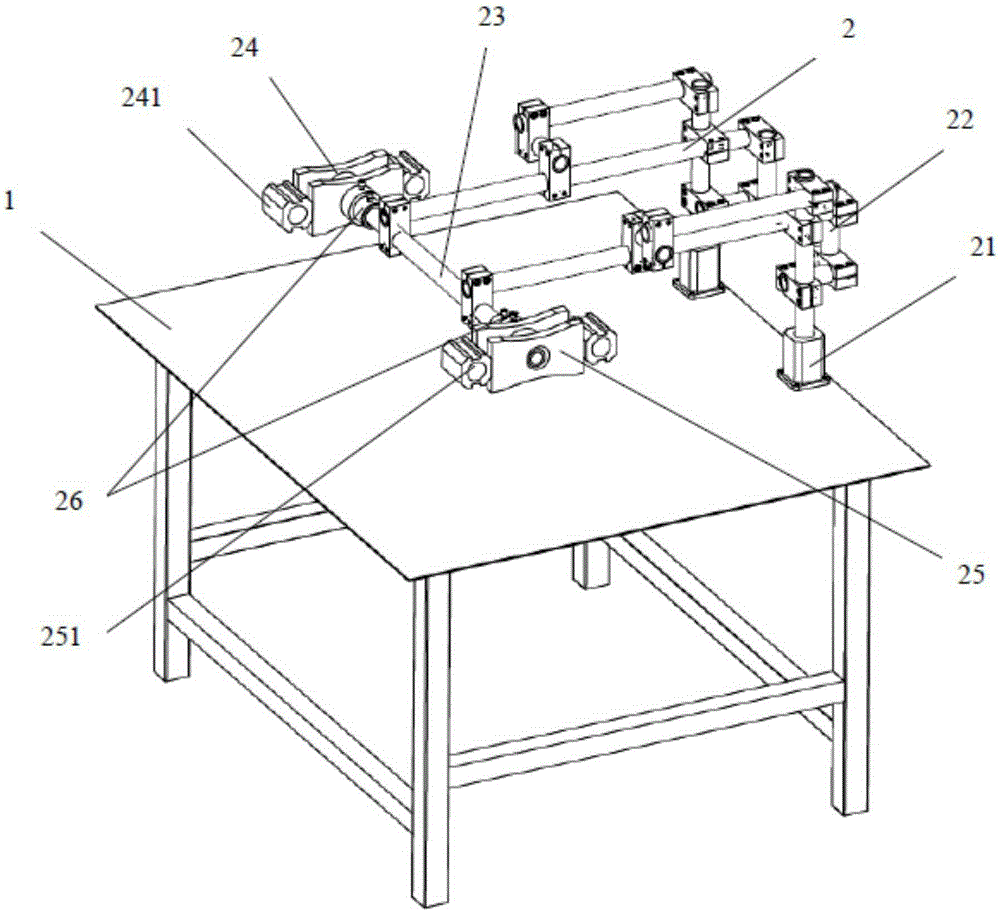

[0017] figure 1 It shows an overall structural diagram of a pre-installation device for a manipulator end picker. The pre-installation device for a manipulator end picker is mainly composed of a workbench 1 and a pre-installation device 2. The pre-installation device 2 is fixed on the On the workbench 1, the upper end of the base 21 is provided with a lifting mechanism, and the lifting mechanism can be stretched up and down along the vertical direction of the workbench 1, and the mounting seat connecting cross bar 23 is provided on the lifting mechanism, The two ends of the connecting cross bar 23 of the mounting seat are respectively connected with a mounting seat, and the two ends of the connecting cross bar 23 of the mounting seat are connected with the mounting seat to be provided with a distance adjusting mechanism 26, and the distance adjusting mechanism 26 can be moved along the The cross bar extends horizontally to lengthen or shorten the distance between the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com